Microfluidics

MICROFLUIDICS & LAB-ON-A-CHIP MANUFACTURING

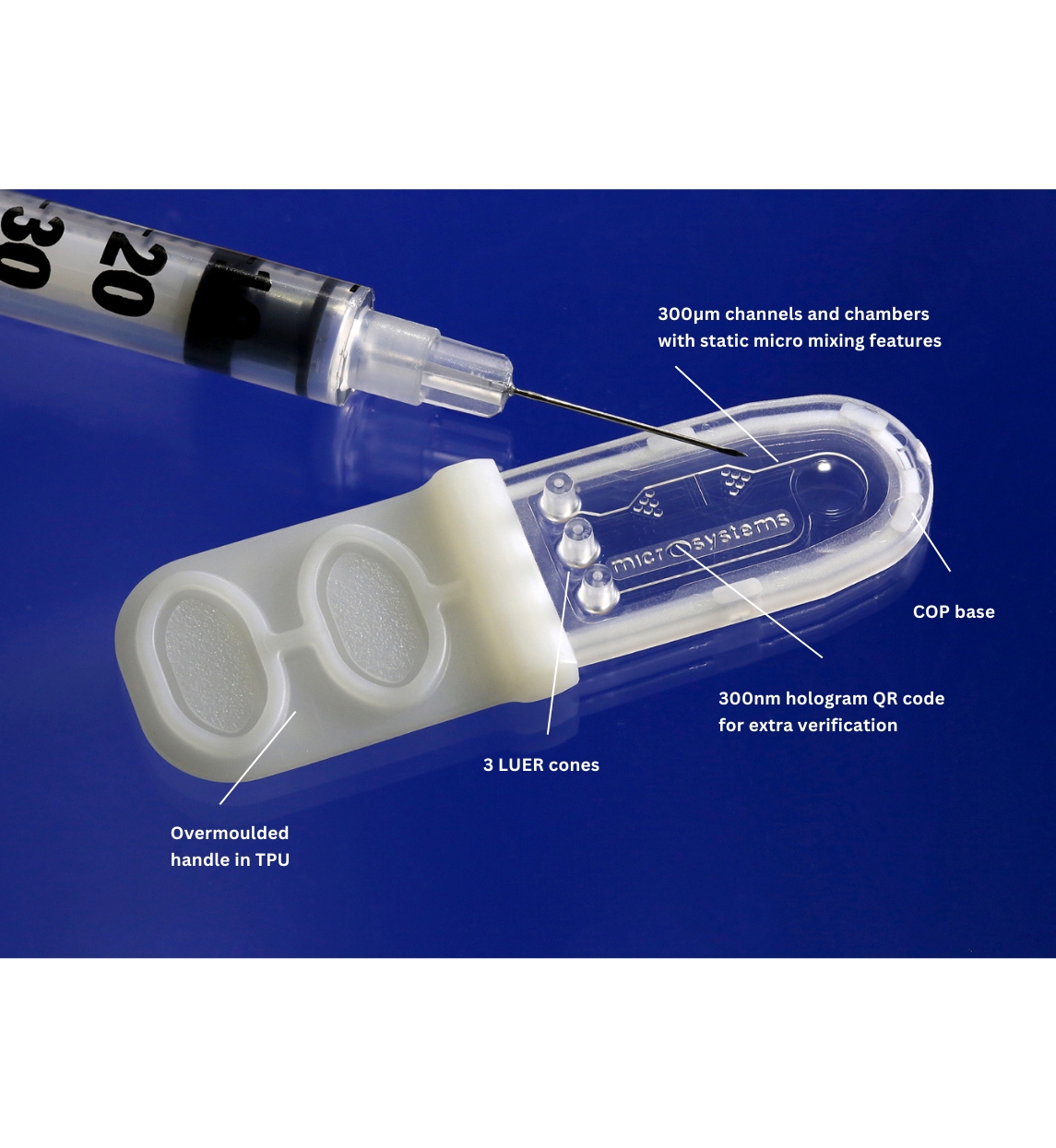

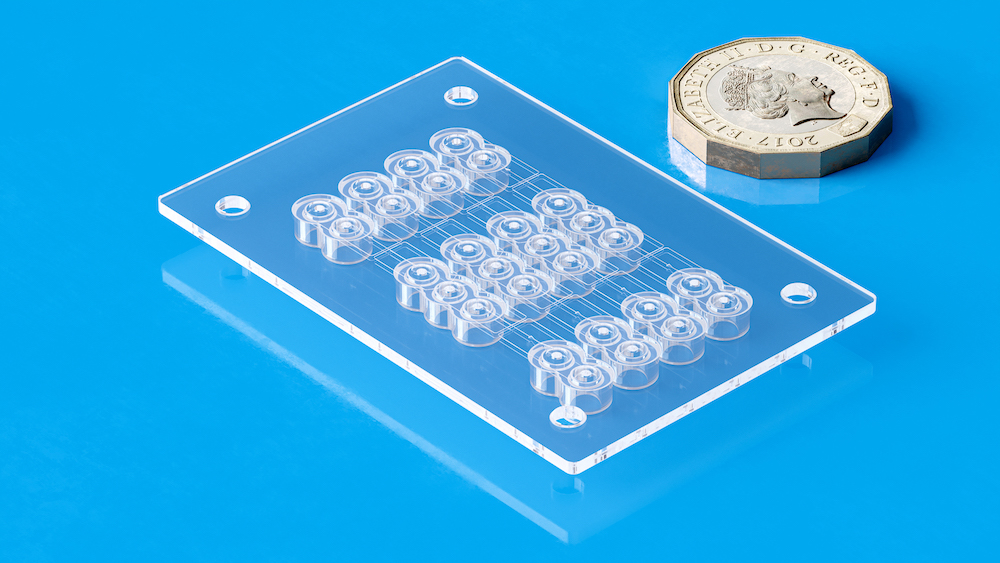

At Micro Systems, we deliver ultra-precise replication of microfluidic features—essential for manipulating capillary flow behaviours such as filling, pinning, and mixing—with sub-micron accuracy down to 0.5 microns. Our proven expertise in high-volume production of injection-moulded microfluidic and lab-on-a-chip devices includes advanced polymers such as PC, COC, and COP. We design and manufacture ultra-precision moulds capable of producing micro- to nano-scale channels, fully customised to your exact microfluidic requirements.

HIGH ACCURACY MICROFLUIDICS DETAILS

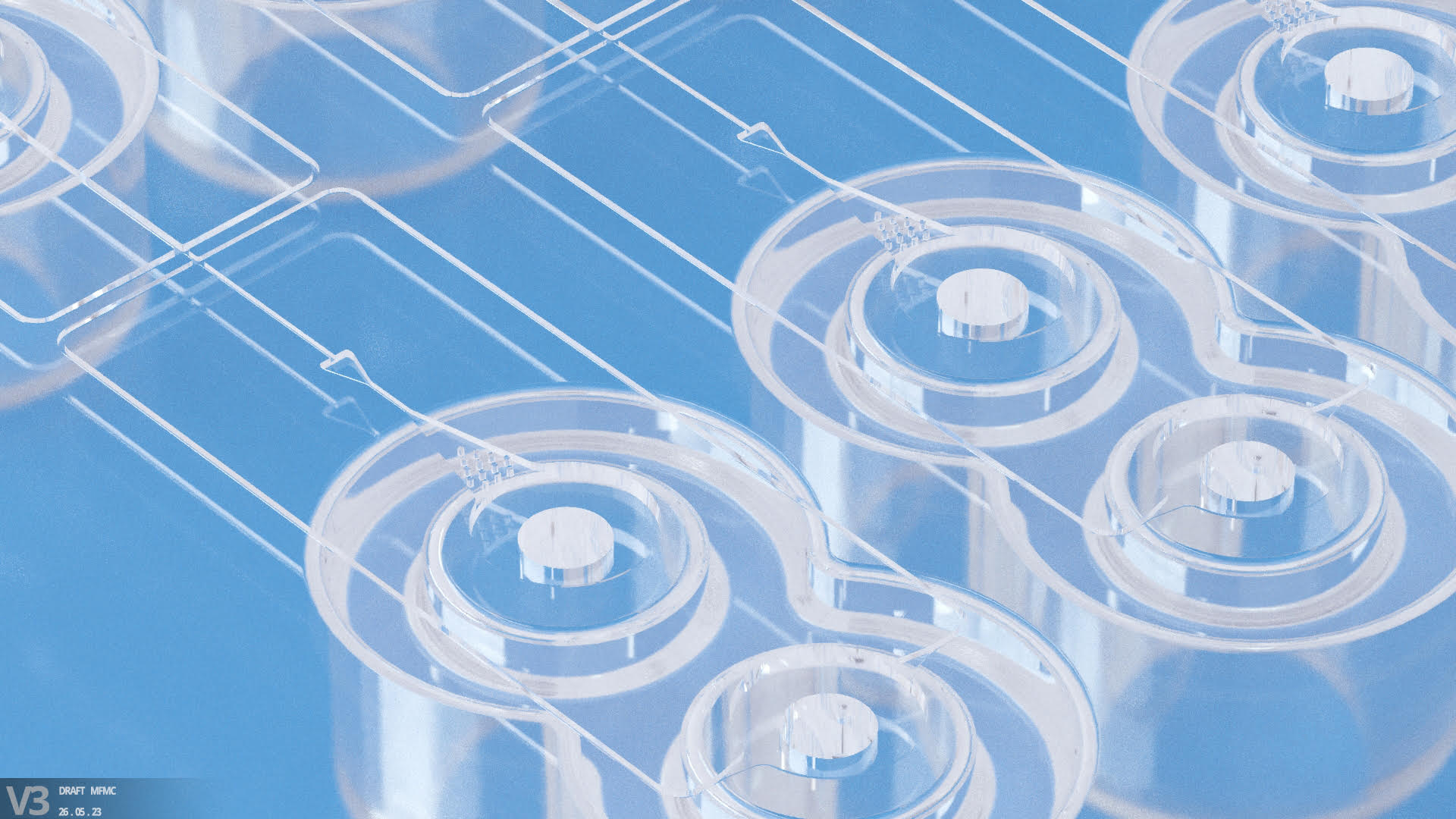

Our ultra-precise manufacturing processes support the integration of barcoded hydrogel beads, cells, and partitioning oil into single-cell emulsion droplets—crucial for single-cell gene expression and immune profiling in genomics. We engineer inline filters and support structures directly within the microchannel architecture, with feature sizes typically between 10 and 50 microns, enabling precise flow control and cell selection. Each moulding solution is custom-developed to ensure flawless surface replication and exceptional feature definition at the micro-scale.

Read more about Microfluidics on our Blog.

INTEGRATED OPTICS

Our integrated optics enable continuous capillary flow to ensure 100% filling of inspection chambers, supporting precise optical laser detection via Frustrated Total Internal Reflection (FTIR) to identify magnetic nanoparticles.

Through extensive research into tool insert materials, manufacturing processes, and microfluidic production techniques, our integrated optics—traditionally machined in nickel inserts—can now be produced in hardened stainless steel (50 Rc), meeting the demands of high-volume component moulding.