How to find the right micro moulding supplier?

Selecting the right supplier is crucial for project success, especially in micro moulding, where complex products require strict standards and procedures for global sales. This process often involves more time and detailed evaluations.

Partnership from Day 1

Unlike conventional injection moulding, the design and manufacture of mould tooling for micro-moulded components require exceptional precision and specialised skills. A micro-moulding partner should be viewed as a strategic collaborator, not just a supplier, working closely with OEM designers and developers. The ideal partner can offer guidance on the practicality, scalability, accuracy, timescales, and cost-effectiveness of the product concept and design.

When shortlisting potential suppliers, OEMs should consider the level of support and communication methods to ensure effective collaboration throughout the process.

Effective project management is crucial for a successful partnership. A supplier with strong project management capabilities can optimise client satisfaction and project success through clear, organised plans. Project managers help mitigate unexpected costs and delays by providing up-to-date information to all relevant stakeholders.

A strong supplier relationship also enables OEMs to understand the supplier’s values, business approach, and sustainability, ensuring alignment. For projects with future expansion potential, OEMs should assess the supplier’s ability to scale resources to meet growing demands.

The chosen micro moulding supplier should have the required experiences, technology and capability to meet the future demands from OEMs. (Photo: Micro Systems)

Tooling/Material expertise

Micro moulding presents unique challenges due to the extremely small sizes of components, often down to a fraction of a human hair. Materials behave differently at this scale, making it difficult for conventional injection moulding companies to undertake micro moulding projects. The selected partner must possess specialised knowledge in tooling and materials to ensure that the chosen material and mould designs can support the scalability and durability of the final parts.

Depending on the project’s nature—whether a prototype, mass production, medical, or non-medical—material experts from the supplier should provide valuable input from the outset, minimising the risk of errors and inefficiencies due to unsuitable materials.

Suppliers should also demonstrate their expertise through samples from previous projects, showcasing their capability to produce moulds and components to the required micro-scale.

Technology and In-house production

Due to the complexity and tight relationships between mould components, it is vital to choose the supplier that has the capability to design and manufacture micro moulds in-house. As the heart of any micro moulding project, micro moulds require a combination of unique expertise and state-of-the-art technology. Top micro moulding manufacturers invest millions annually in training, advanced equipment, and manufacturing technologies. However, success also hinges on seamless collaboration between departments (design, tooling, etc.) within the supplier’s facility. Suppliers with both micro tooling and micro moulding capabilities on-site are ideal for turnkey projects, as they can quickly address issues in the final moulding stage, avoid miscommunication, and enhance overall efficiency.

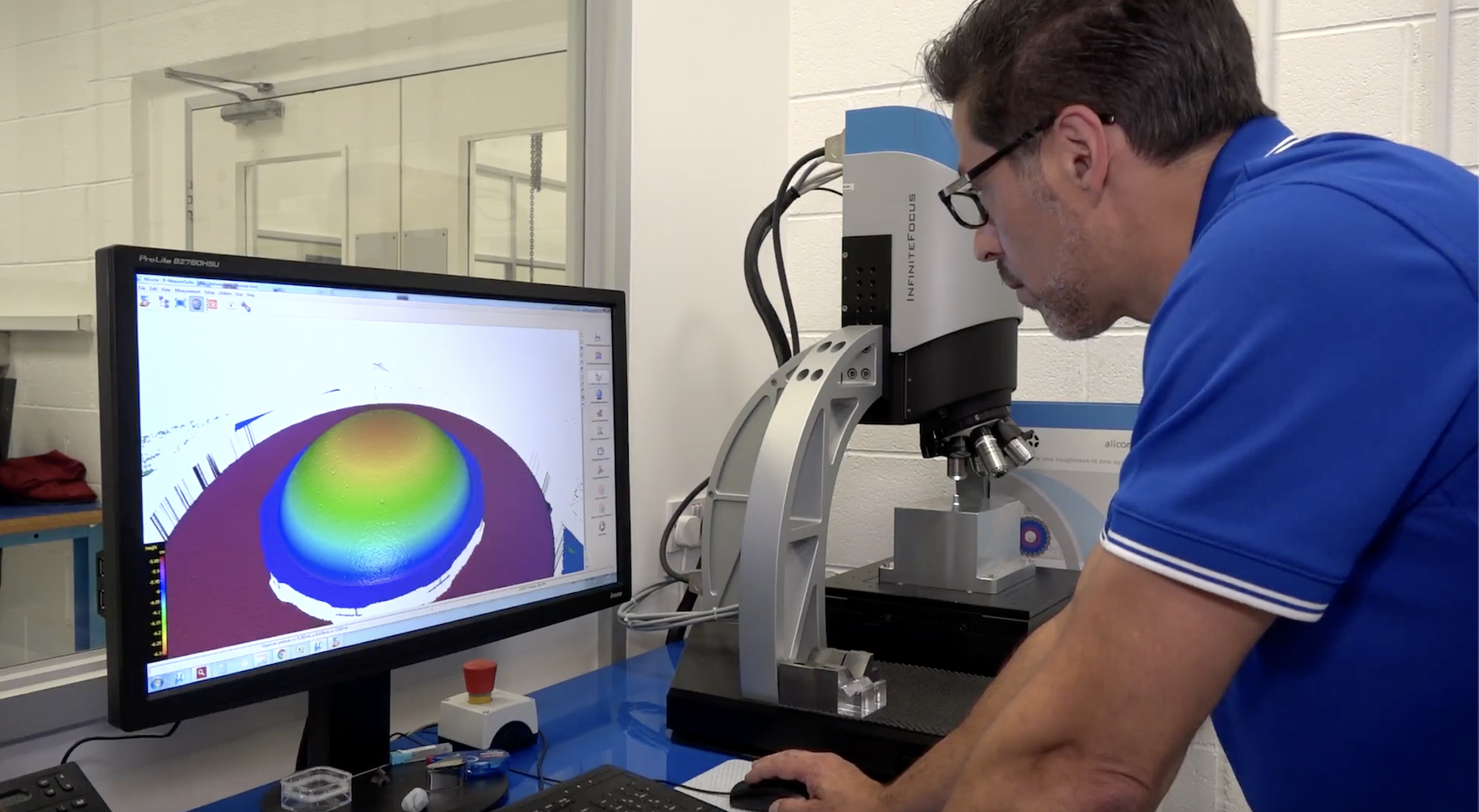

A critical part of micro moulding that differs it from conventional injection moulding is the vital role of quality assurance and measuring. Micro moulding suppliers having the ability to carry out quality checks with an inhouse Micro Metrology department could avoid any error in measurement due to the change in environments between the production site and metrology site. A trusted supplier could also prove their highest attention to quality assurance by heavily investing on the top micro metrology equipment.

A critical part of micro moulding that differs it from conventional injection moulding is the vital role of quality assurance and measuring. Micro moulding suppliers having the ability to carry out quality checks with an inhouse Micro Metrology department could avoid any error in measurement due to the change in environments between the production site and metrology site. A trusted supplier could also prove their highest attention to quality assurance by heavily investing on the top micro metrology equipment.

Choosing a supplier with recognised Quality Management System (QMS) certifications, such as ISO 9001 or ISO 13485, is essential, particularly for OEMs in the healthcare and medical sectors. These certifications ensure that the supplier follows formal processes, procedures, and roles in line with globally accepted standards to meet project objectives, whether for tool manufacture or micro injection moulding.

With the green revolution across industries nowadays, another important factor to be considered when choosing the ideal micro moulding supplier is Corporate Social Responsibility (CSR). As sustainable procurement becomes standard, especially for international businesses, selecting a micro moulding supplier with a clear CSR approach and high transparency enables OEMs to align their own CSR performance effectively.

After-sales service support

The relationship between OEMs and micro moulding suppliers extends beyond delivery. Trusted suppliers provide prompt after-sales support, demonstrating professionalism and commitment to long-term partnerships. Given the potential for faults or scheduled maintenance in micro moulds, suppliers must communicate effectively with OEMs to ensure timely and cost-efficient resolution of issues.

Conclusion

In an environment where marketing can be misleading, it’s crucial to distinguish between suppliers who claim to mould micro components and those with the expertise to do so. Investing time in selecting the right micro moulding partner from the start enables OEMs to save time and costs, reduce faults, and establish a trusted supplier for future projects.

When making the final decision on the chosen micro moulding supplier, OEMs should ask themselves those important questions:

- Does the supplier possess the necessary production capabilities?

- Does it have the ability to produce/design moulds/micro moulded parts quickly enough to meet requests at the stages of product development, market launch, or production?

- Does it provide the products at a reasonably competitive price?

- Does it have the necessary degree of quality control (in Healthcare/Medical, in Food and Drink, etc.)? Does it have the required certifications for the targeted industry?

- What is its method of communication? Who will be responsible for the communication between the 2 parties?

- Does it work with other contractors for your project? If yes, how do they control the quality of their suppliers?

- Does it provide after-sale services (maintenance, servicing, etc.)?

- Does it have the required scalability and flexibility for the future expansion of the project?

Micro Systems specialises in the design, manufacture and validation of ultra precision micro moulds for the medical, pharmaceutical and optical markets, at the same time, the development and use of micro and nano technologies in the design and manufacture of injection moulded components. We have a dedicated micro moulding facility, and have ISO13485 and ISO9001 certifications. For more information, please Contact us or visit our website.