Why choose Injection Moulding for Medical Device Manufacturing?

Medical devices are a fundamental element of the Health Systems in any country, essential for the diagnosis, treatment and rehabilitation of illnesses and diseases. According to a recent report, the size of the global market for medical devices, estimated at USD 512.29 billion in 2022, is expected to increase by USD 799.67 billion by 2030, with a CAGR of 5.9% from USD 536.12 billion in 2023.

To comply with the rigorous regulatory and quality standards in medical device manufacturing, plastic injection moulding is extensively employed for the production of medical components and parts. This technique provides a cost-effective and efficient solution for manufacturing large volumes of precision-engineered, high-quality plastic components, ensuring exceptional accuracy and consistent performance.

Benefits of Plastic Injection Moulding

Plastic injection moulding provides distinct advantages over alternative plastic manufacturing methods in the production of medical devices—advantages that are essential for ensuring optimal performance, reliability, and adherence to regulatory standards in healthcare applications globally.

Superior properties and Micro dimensions

Plastic injection moulding offers outstanding versatility, compatible with a wide array of medical-grade materials, allowing product designers to meet stringent performance requirements. This technique accommodates the use of durable, high-strength plastics that can endure abrasive conditions, mechanical stress, and impact without cracking, shattering, or deforming. Many of the polymers employed in injection moulding also provide excellent thermal resistance, making them ideal for repeated sterilisation processes, such as autoclaving. Furthermore, these materials exhibit superior resistance to contamination and typically require minimal sterilisation, thereby supporting compliance with rigorous regulatory standards, including FDA guidelines, while also helping to reduce overall component costs.

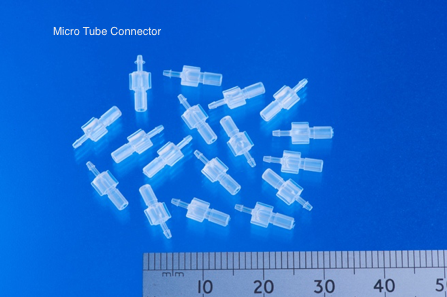

Additionally, injection moulding allows for the production of very small medical parts, down to a fraction of a human hair. For example, at Micro Systems, our experts in micro mould and micro moulding are working on projects for extremely small and precise parts, with accuracy down to a fraction of a micron, and surface finish of less than 10 nm. Or the increasing popularity of microfluidic devices also requires the use of micro mould and micro moulding to produce parts of tolerance as low as +/-0.001mm, with integrated optics.

Mass production and Cost efficiency

Injection moulding is very cost-effective when it comes to mass production, as the bulk injection moulding will reduce the cost-per-part overall by dividing the expense of tooling over thousands of pieces. The design and manufacture of the moulds and toolings is the initial step in the production of any injection-moulded product, which could require quite an investment in time and finance, especially for complicated ones like micro parts. Once the tooling is established, plastic injection moulding facilitates the rapid and cost-effective production of large quantities of identical medical components, ensuring consistent quality and precise dimensional accuracy. This makes it an optimal solution for the high-volume manufacturing of single-use medical devices, such as tubing, containers, syringes, clippers, and other disposable items, where precision, repeatability, and strict adherence to hygiene standards are paramount.

Furthermore, advancements in injection moulding technology now allow for highly precise control over the entire manufacturing process, significantly reducing production times while ensuring exceptional accuracy and tight tolerances in the final components. For instance, at Micro Systems, medical micro moulding is conducted using dedicated production cells, each equipped with robotic handling systems for component separation or tray packaging. These are integrated with in-line camera vision systems, which provide real-time inspection to ensure component integrity and quality assurance prior to packaging.

High aesthetics and design flexibility

Medical devices are increasingly designed to be not only compact and portable but also aesthetically appealing, as the demand for visually attractive products grows in order to avoid the typical institutional appearance. Plastic injection moulding offers a broad range of options to meet these aesthetic requirements, from specific surface features for identification and functionality to diverse choices in colouring and transparency. Additionally, this manufacturing method provides medical device designers with greater flexibility, enabling multiple functionalities to be integrated in a single step of the injection moulding process, rather than relying on the combination of various techniques to achieve the desired outcomes.

Advanced moulding techniques like over-moulding, thin-wall moulding, 2-shot moulding, 2K moulding, etc. at Micro Systems can provide further complexity, hence helping customers in achieving high precision products without foreign materials or costly assembly processes.

Applications of Injection Moulding in Medical Device

Plastic injection moulding is used in a variety of ways in the medical device sector, for a range of products like:

- Implantable parts

- Containers such as test tubes and beakers

- Instruments and components for surgery

- Components and equipment for drug distribution

- Orthopaedics

- Housings and casings for equipment used in laboratories and the medical field

- Dental X-ray equipment components

- Surgical Equipment

- Diagnostics: Microfluidics, Lab-on-a-chip

Medical-grade plastic used in Injection Moulding in Medical Device

Medical-grade plastic is commonly defined as plastics that are particularly made to produce medical equipment and devices. In the medical industry, the usage of biocompatible plastics is intended to promote healing and recovery without resulting in unfavourable outcomes including injuries, allergic responses, or toxic reactions.

The injection moulding process enables the use of a wide range of medical-grade plastics, selected based on the specific properties and performance requirements of the components or parts. Commonly used medical-grade plastics for manufacturing medical device components via injection moulding include:

- Polypropylene (PP): one of the most widely utilised polymers in the sector because of its toughness and toughness, strong chemical bonding resulting in a superior material for making test tubes and beakers for use in medical equipment.

- Polyethylene (PE): a popular plastic polymer made up of a large number of ethylene polymers, with high tensile strength and stiffness, durability to extreme environmental conditions, including sterilisation.

- Silicone: a chemically inert chemical substance that resembles synthetic rubber with exceptional mechanical qualities and compatibility with biological tissues, ideal for making items and gadgets with high flexibility at an affordable cost, including connectors, tubing, contact lenses, breast implants, medication delivery systems, and catheters, etc.

- Polycarbonates (PC): a reinforced technical thermoplastic with exceptional mechanical qualities, including toughness, flexibility, resistance to abrasion, breaking, temperature, etc., while appearing to be transparent, very compatible with bodily tissues, hence perfect for producing a variety of medical plastic injection parts, including clear masks, safety gear, oxygenators, etc.

- Polyether Ether Ketone (PEEK): a common thermoplastic material that has exceptional resilience to extreme circumstances, including those involving radiation, high temperatures, chemicals, wear and tear, etc., mostly used to make surgical and medical implants.

The material chosen for the product depends on the required strength, operating environment (chemical and temperature resistance during operation, sterilisation procedures, etc.), industry requirements (FDA and medical industry standards), and other factors like costing, portability, practicality, etc.

Looking for a medical device mould and injection moulded part manufacturer?

Micro Systems specialises in the design, manufacture and validation of ultra precision micro moulds for the medical, pharmaceutical and optical markets, at the same time, the development and use of micro and nano technologies in the design and manufacture of injection moulded components. We have a dedicated micro moulding facility, and have ISO13485 and ISO9001 certifications. Contact us today to start planning your micro injection moulding project and take advantage of our decades of micro moulding expertise.