Sustainable Design and Manufacturing in Plastic Injection Moulding

Sustainable Design and Manufacturing in Plastic Injection Moulding are key factors in promoting the sustainability of the industry with increasing demands from the health care and medical sectors. According to a recent report by Absolute Reports, the size of the world market for medical micro injection moulding, which was estimated at USD 240.2 million in 2022, is anticipated to grow at a CAGR of 10.42% over the course of the forecast period and reach USD 435.26 million by 2028.

What is Plastic Injection Moulding?

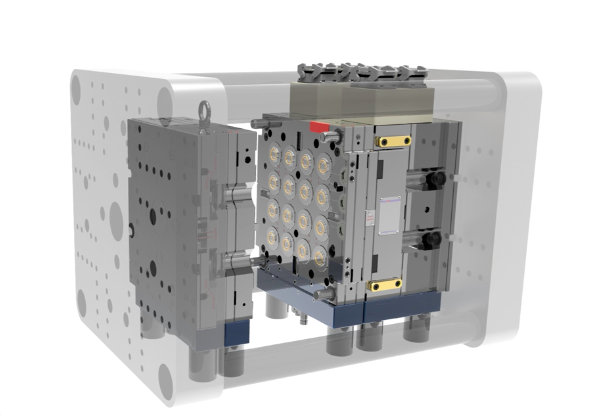

Plastic injection moulding is a standard procedure for producing plastic components used in a variety of industries. Plastic injection moulding is the process of melting plastic pellets (thermosetting / thermoplastic polymers) and injecting them under pressure into a mould cavity, where they fill and solidify to form the finished product. It is a quick manufacturing technique that allows for the creation of large numbers of the same plastic product in a short period of time.

Plastic injection moulding is a popular method for manufacturing plastic components for the medical, aerospace, car, and toy sectors. This method brings a number of benefits, especially in terms of flexibility, efficiency, consistency, cost-effectiveness and quality.

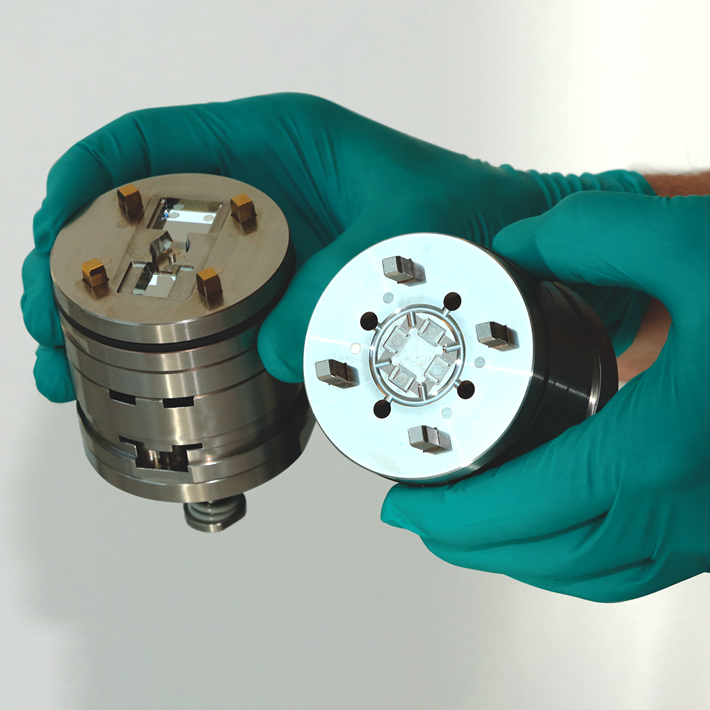

Micro moulding is a growing specialisation within the plastic injection moulding industry, which creates plastic components with shot weights ranging from 1 to 0.1g and tolerances ranging from 10 to 100 microns. This moulding technology enables producers to create complex tiny geometries with the greatest accuracy and precision possible, mainly for the use in medical devices, drug delivery, sensors and other high-precision micro-tolerance thermoplastic components.

What is Sustainable design and manufacture?

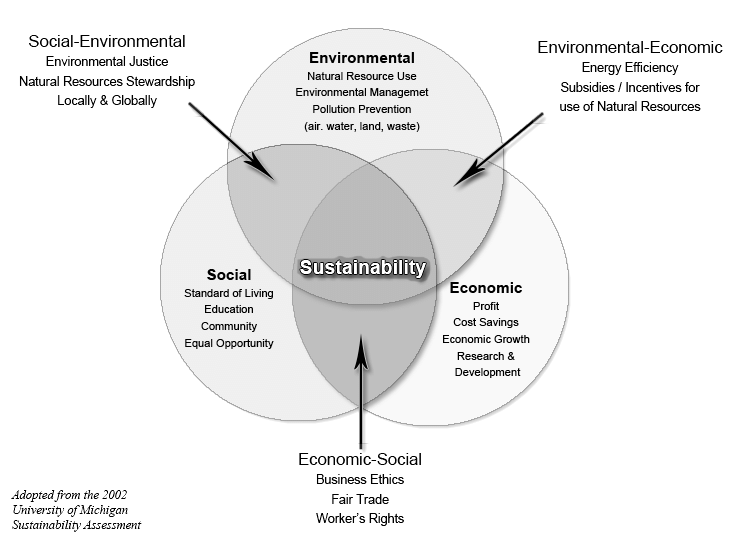

Sustainable design and manufacturing is a systems approach to the development (design & manufacture) and distribution (supply chain) of goods and services using cost-effective procedures. The aims of these methods are to reduce negative environmental impacts as well as energy and natural resource usage, and to implement socially responsible practices for employees, local communities and societies across the whole product and service life cycle.

Tripple Bottom Line (Source: Sustainability Assessment and Reporting for the University of Michigan’s, 2002, p.8) is crucial for Sustainable Design and Manufacturing in Plastic Injection Moulding

Based on the objectives of sustainable design, the design stage has the biggest influence in defining how a product’s raw materials, production, distribution, consumption, maintenance, and disposal will affect the environment. According to the European Commission’s Sustainable Product Policy, up to 80% of a product’s negative environmental effect is finalised at the design stage. As a result, it is critical for designers and producers to analyse and minimise environmental implications during the design process, before finalising the product design. Design for sustainability hence enables the relevant stakeholders to conduct a thorough review of all the many factors and produce an environmentally sound product. Some principles of sustainable design include dematerialisation, modular design, prioritising green energy sources, product-service systems migration, longevity in design, reduction and elimination of long-distance outsourcing, and investment on simulation.

In recent years, doing business based on sound sustainable practices is increasingly important in the eyes of investors, regulators, consumers, and the communities in which the businesses operate. For example, the UK government will enact the world’s most aggressive climate change target, reducing emissions by 78% by 2035 compared to 1990 levels, or as a result of COVID-19 pandemic, consumers are moving towards a more sustainable shopping habit, with 34% of customers choosing brands with ecologically friendly practices over those that do not (Deloitte survey). Especially, according to the UK’s Carbon Trust, most firms could lower their energy expenditures by up to 20% with a minimal investment, a savings that could correspond to a 5% rise in total revenues.

Profiting from sustainable manufacturing is not simply a game just for large corporations, but new companies and small enterprises can also play an important role. Start-ups and small and medium-sized firms (SMEs) can significantly profit from their sustainable business models, from attracting more customers, creating new business streams and increasing its competitiveness in a growing global market.

Check out Micro Systems 2022 CSR Report

Sustainability in Micro Plastic Injection Moulding

Sustainability has been increasingly more important among plastic injection moulding businesses, with improvements and innovations reshaping the industry. Most common practices, many of which are currently being applied at Micro Systems (UK) include:

Sustainability has been increasingly more important among plastic injection moulding businesses, with improvements and innovations reshaping the industry. Most common practices, many of which are currently being applied at Micro Systems (UK) include:

- Optimise injection mould design to decrease material waste, supported by effective computer-aided designs and advanced prototyping systems before finalising the ultimate designs;

- Reduce and recycle scrap plastic at source through effective quality control procedures;

- Improve cycle times through advanced process control and automation;

- Ship locally and prioritise purchasing from local suppliers;

- Minimise packaging;

- Increase in green energy sources, while reducing energy consumption through energy-efficient machines, facility and frequent maintenance;

- Recycle post-consumer products;

- Educate customers and stakeholders on sustainability in micro injection moulding through sharing knowledge and best practices.

A highly effective solution is rapid prototyping. Businesses could reduce the risks of design mistakes while lowering possible scrap created by the early production runs of an imperfect design, by refining and enhancing it before deciding on full production.

Working closely with our customers from the first stages, from design to manufacturing, enables Micro Systems (UK) to maximise design efficiency and simplify production, hence resulting in a higher level of sustainability of the final products for both ourselves and our customers. Micro Systems (UK) is devoted to sustainability and strives to provide environmentally friendly products and procedures.

Contact us today to start planning your micro injection moulding project and take advantage of our decades of micro moulding expertise.