Process Validation Protocols for FDA-Compliant Medical Moulding

Medical-grade moulding is a highly regulated discipline where consistent product quality and patient safety are paramount. Under FDA guidance, process validation for medical moulding must demonstrate that manufacturing processes reliably produce components meeting predetermined specifications.

1. Regulatory Foundation & Quality Management Systems

The U.S. Food and Drug Administration’s Quality System Regulation (21 CFR Part 820) mandates process validation when final product quality cannot be fully verified by inspection [FDA, 2024]. Medical moulding operations typically align with ISO 13485:2016, which defines requirements for design controls, risk management, cleanliness, documentation and personnel competence [ISO, 2016]. These standards establish the quality management system essential for FDA compliance.

2. The Three-Stage Process Validation Paradigm

FDA-aligned medical moulding validation protocols employ a three-stage structure: Process Design, Process Qualification, and Continued Process Verification [EMA, 2020].

Stage 1: Process Design

Manufacturers define critical quality attributes (CQAs) and critical process parameters (CPPs), variables such as mould temperature, injection pressure, and cooling time that influence part quality [Smith, 2021].

Stage 2: Process Qualification

This stage comprises IQ, OQ, and PQ (Installation, Operational, and Performance Qualifications):

- IQ (Installation Qualification) verifies proper installation of machines, utilities, tooling and software, complete with calibration records and environmental conditions [Crescent Industries, 2023].

- OQ (Operational Qualification) defines and challenges operating limits (e.g. melt temperature, cycle time), frequently using design of experiments (DOE) to ensure robustness [Aprios, 2023].

- PQ (Performance Qualification) confirms that under routine production conditions, the process consistently creates parts meeting specifications across multiple runs. Statistical measures (e.g. Cpk ≥ 1.33) are documented in the Validation Master Plan (VMP) [Medical Micro Moulding, 2022].

Stage 3: Continued Process Verification (CPV)

Once qualified, monitoring must continue, tracking output data, detecting trends, and initiating corrective actions when processes drift from predefined limits [FDA, 2011].

3. Associated Validation Elements

Material and Biocompatibility Validation

Medical-grade resins must meet ISO 10993 and USP Class VI biocompatibility requirements. Tests include cytotoxicity, sensitisation, systemic toxicity and implantation studies [ISO, 2018].

Dimensional Inspection & Functional Performance

Precision is critical. Measurements using coordinate measuring machines (CMMs), laser scanners or optical comparators enable verification of dimensional tolerances and functional features [Marlee-Texen, 2023].

Sterilisation & Cleaning Validation

Materials and parts must withstand intended sterilisation methods (autoclave, EtO, gamma), compatibility validation is essential [Accelerated Plastics, 2022]. Cleaning validation ensures that residues, chemical or microbial, are removed to predetermined, risk-based limits [EMA, 2020].

4. Risk Management & Change Control

ISO 14971 risk management must be applied throughout the validation lifecycle. Techniques like FMEA guide identification and mitigation of failure modes. Any changes impacting CPPs, tooling, materials, or processes require change control assessment, potential re-validation, and documentation by a Change Control Board (CCB) [ISO, 2019].

5. Documentation & Audit Readiness

Comprehensive documentation ensures traceability and audit readiness:

- Validation Master Plan (VMP) and Protocols: high-level strategy and individual IQ/OQ/PQ procedures.

- Device Master Record (DMR) & Device History Record (DHR): detailed design, process, material, batch and test records [Accelerated Plastics, 2022].

- Mould History Record and Process Parameter Logs: track equipment history and each production run [Aprios, 2023].

- Inspection, Deviation Reports, and CAPA Logs: document non-conformities and corrective actions [Medical Micro Moulding, 2022].

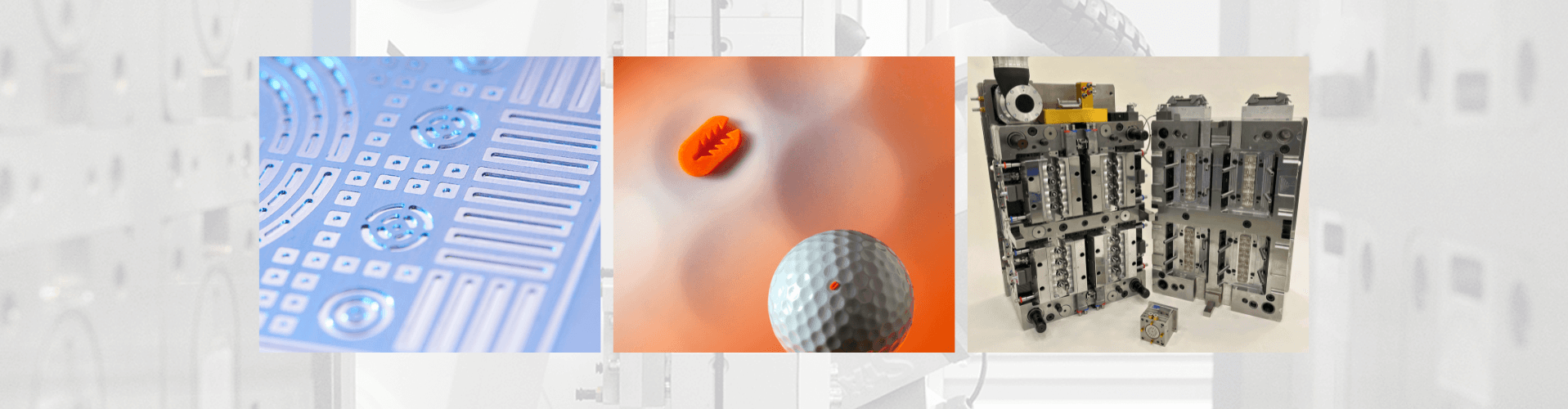

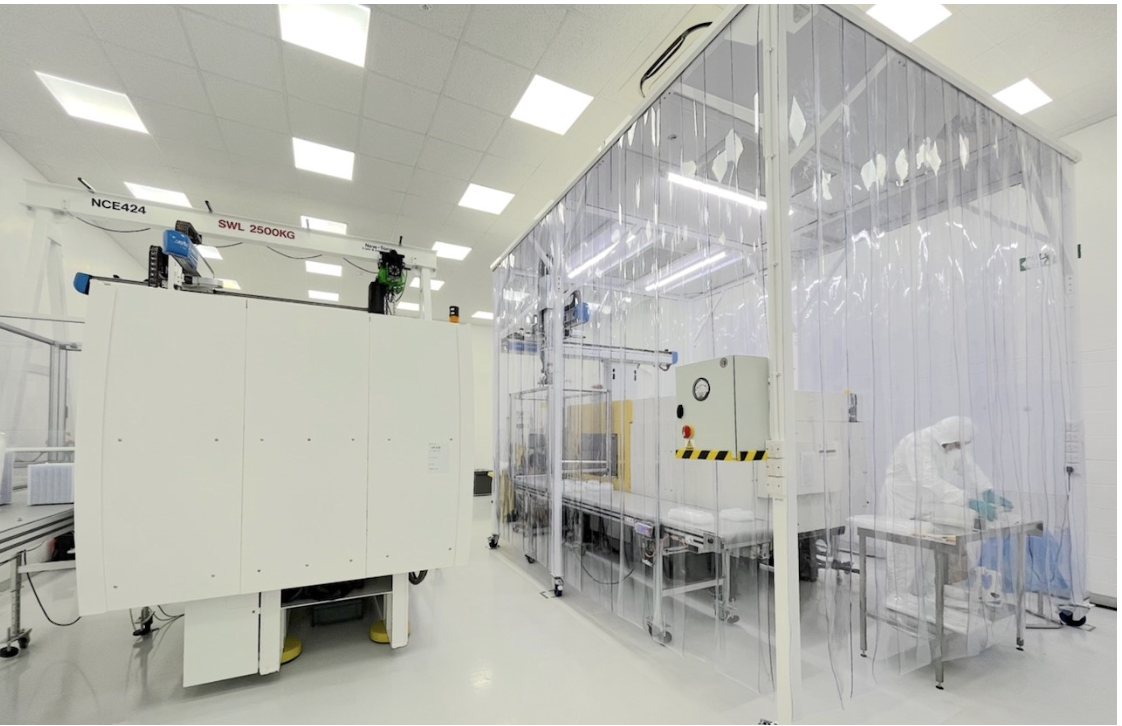

6. Guaranteeing Compliance: How Micro Systems Supports FDA-Validated Moulding

Micro Systems, a leading provider of medical moulding solutions, ensures FDA-compliant process validation through an integrated approach. Our facilities operate to ISO 13485 standards, with in-house metrology laboratories equipped for CMM, optical and CT scanning, enabling full dimensional verification. The company applies rigorous IQ/OQ/PQ protocols, supported by DOE methodologies, to guarantee process robustness. By embedding ISO 14971 risk management into design and production, and maintaining cleanroom-controlled environments, Micro Systems ensures every moulding process meets the required validation requirements.

7. Best Practice Overview

- FDA-Required Process Validation: IQ/OQ/PQ lifecycle + CPV ensures consistent quality [FDA, 2024].

- Standards Compliance: adherence to ISO 13485, ISO 10993 and 21 CFR Part 820 ensures regulatory alignment.

- Risk-Based Approach: FMEA, change control, and CAPA reduce lifecycle risk.

- Robust Documentation: VMP, DMR/DHR, inspection and deviation records safeguard audit readiness.

- Quality beyond Validation: cleanroom control, dimensional checks, sterilisation and cleaning validation ensure continuous compliance.

Establishing effective process validation protocols for FDA-compliant medical moulding is essential for manufacturers delivering precision components. By systematically applying IQ/OQ/PQ validation, rigorous documentation, biocompatibility assessment, sterilisation validation, risk-based change control, and continual monitoring, companies can ensure safe and compliant manufacturing. With its integrated quality systems and validation expertise, Micro Systems is uniquely positioned to have the ability to guarantee the required process validation across the lifecycle of medical moulding projects.

References

- Accelerated Plastics (2022). Medical Device Injection Moulding Compliance. Accelerated Plastics.

- Aprios (2023). Process Validation Compliance in Injection Moulding. Aprios.

- Crescent Industries (2023). Medical Injection Moulding Process Development and Validations. Crescent Industries.

- EMA (2020). Guideline on Process Validation. European Medicines Agency.

- FDA (2011). Guidance for Industry: Process Validation – General Principles and Practices. U.S. Food and Drug Administration.

- FDA (2024). Quality System Regulation (21 CFR Part 820). U.S. Food and Drug Administration.

- ISO (2016). ISO 13485:2016 – Medical Devices – Quality Management Systems. International Organization for Standardization.

- ISO (2018). ISO 10993:2018 – Biological Evaluation of Medical Devices. International Organization for Standardization.

- ISO (2019). ISO 14971:2019 – Application of Risk Management to Medical Devices. International Organization for Standardization.

- Marlee-Texen (2023). Comprehensive Guide to Medical Device Injection Moulding. Marlee-Texen.

- Medical Micro Moulding (2022). FDA and ISO 13485 Compliance Requirements for Auto-Injector Component Moulding. Medical Micro Moulding.

- Smith, J. (2021). Critical Process Parameters in Injection Moulding. Journal of Medical Manufacturing, 12(3), pp. 45–52.