Micro Milling and Micro Metrology in Micro Manufacturing

The emerging techniques in micro and nano manufacturing make it possible to produce extremely complex structures with very few geometric restrictions, high design flexibility and various applications in numerous industries and professions, including medical, electronics, photonics, biotechnology, automotive and aerospace.

Micro milling for ultra-precision geometries

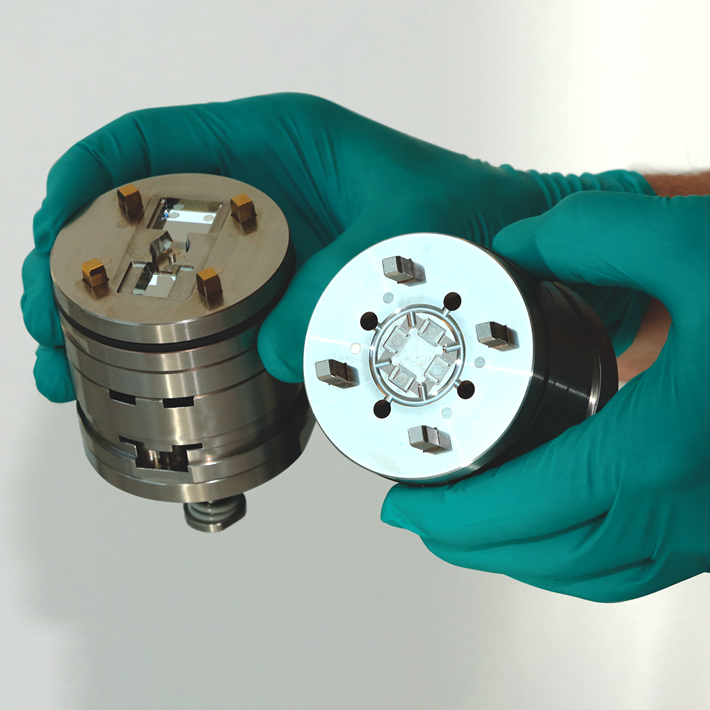

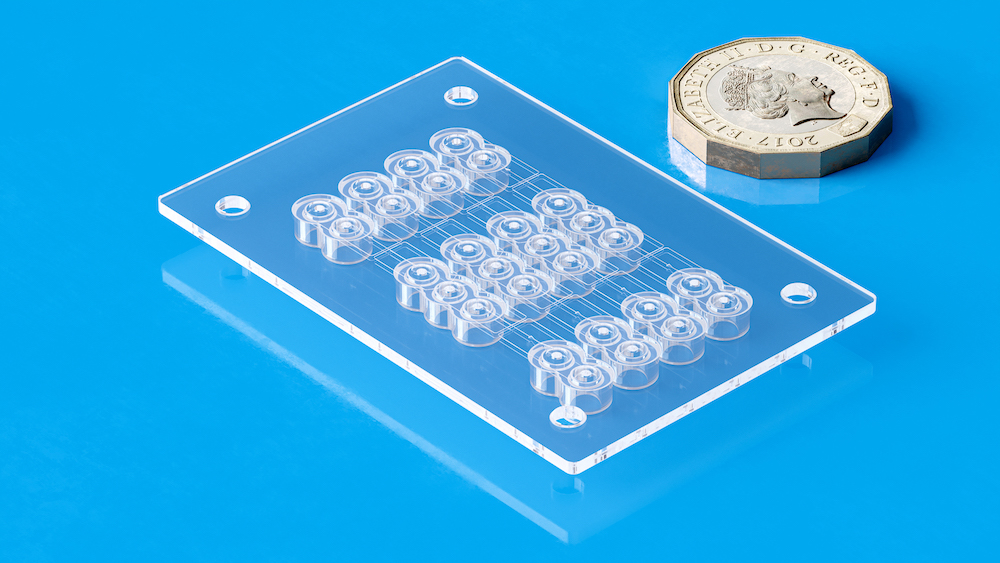

Micro milling is an advanced manufacturing technique utilised to produce highly complex 3D geometries in challenging materials, such as hardened steels. It is particularly well-suited for creating precise, accurate parts with microscale features, achieving tolerances of less than 1 micron in form and dimensional accuracy. Operating at extremely high speeds (50,000+ rpm), micro milling enhances cut quality, improves surface finish, reduces tool wear, and increases machining productivity. In the mould-making industry, micro milling enables the creation of highly accurate, high-aspect ratio microstructures (such as microchannels, ultra-thin walls, and microarrays) and precisely patterned surface microstructures. These features are critical in applications like microfluidics and lab-on-a-chip technologies. For instance, Micro Systems has successfully used micro milling to manufacture microfluidic moulds for single-cell immune profiling and gene expression technologies, producing moulded devices with 0.5-micron reproducibility using polymers such as PC, COC, and COP. These moulds incorporated 50-micron microchannels, integrated optical features, and a surface finish of less than 20-nanometre Ra.

Figure 1: Microfluidic chips with incorporated 30-micron microchannels, integrated optics features and a surface finish of less than 20-micron Ra.

In a recent project, Micro Systems utilised the Kern Pyramid Nano machine within a temperature-controlled environment to achieve a positional accuracy of 0.0005 mm (0.00002”). With a spindle speed of 55,000 rpm, the machine was able to process fully hardened steel using cutters as small as Ø0.050 mm (0.002”). At this level of micro-manufacturing, proprietary techniques are employed to ensure precise cutter alignment, resulting in finished parts without any visible cutter steps. Additionally, the UK-based mould maker meticulously controls all critical factors, including material properties, tool geometry, air temperature, manufacturing environment, and cutting parameters, to ensure optimal efficiency and precision in the production of the desired outcomes.

Using innovative CAD/CAM softwares, collective experience and knowledge on material performance, time-cost efficient machining strategies and micro milling excellence from designers, technicians and engineers, Micro Systems is advancing into much smaller ranges of dimensions with extremely high levels of precision, accelerating the disruptive miniaturisation trend especially in the medical and diagnostic sectors.

Micro metrology enabling manufacturing precision

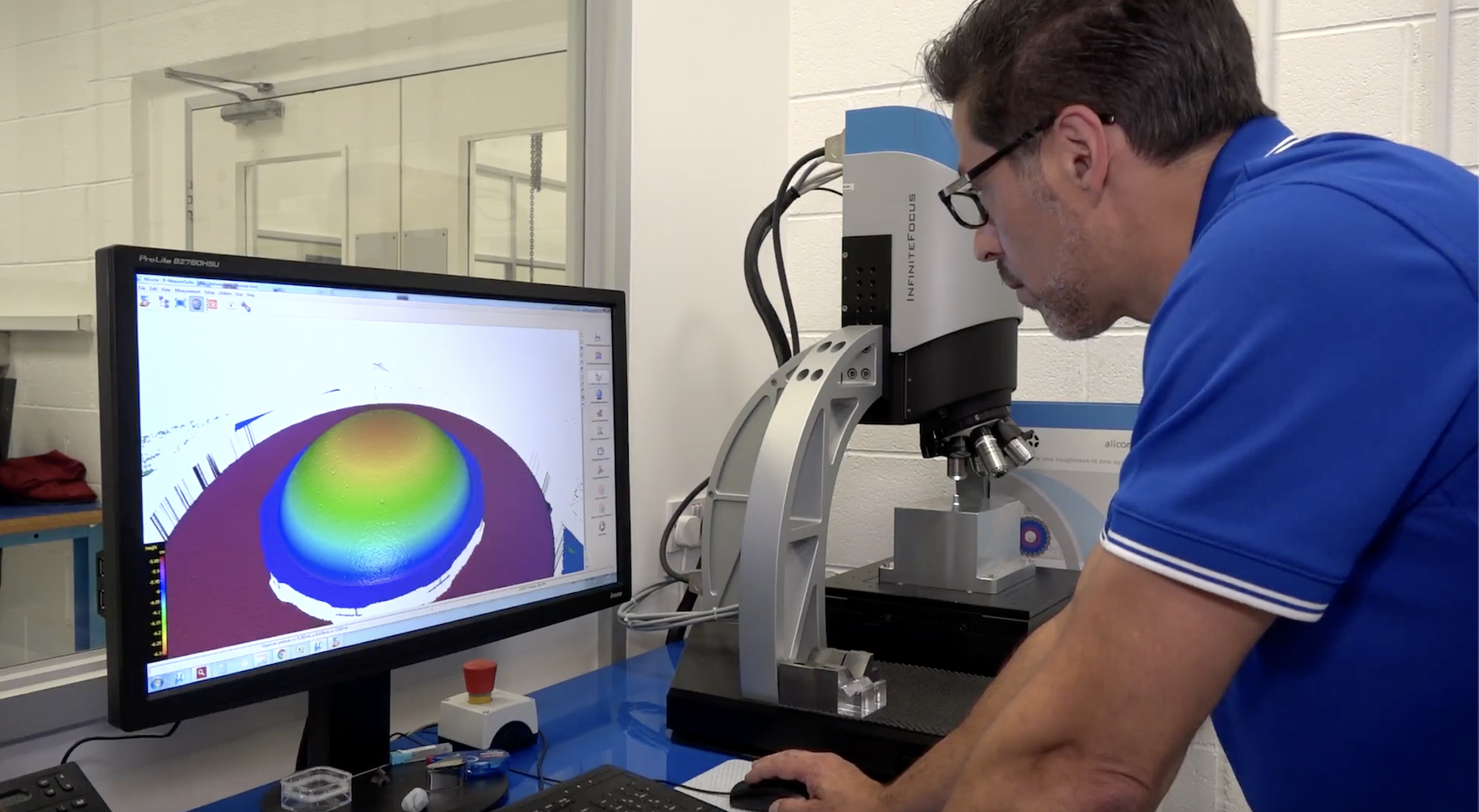

The increasing complexity of micro-manufacturing necessitates advanced measurement and verification techniques, which are provided by micro metrology. To ensure quality assurance for micro parts across various length scales, a range of advanced micro metrology technologies and systems are required. These include non-contact white light interferometry (for surface measurement and inspection) and focus-variation (for shape and roughness measurement), which generate colour 3D models for comparison against CAD models and other data analyses. The ability to accurately scan and measure components during the manufacturing process can significantly reduce project lead times, enabling faster iterations of design or material adjustments, providing more reliable measurements, and potentially lowering costs.

Certain machines, such as the Keyence VHX6000 digital microscope, are employed to conduct in-process checks (IPCs) on parts while they remain on the machine. The capability to mount the micro metrology system directly onto the KERN machine for IPCs ensures that no positional accuracy is compromised during the loading and unloading of parts for measurement checks. Additionally, Micro Systems uses the Alicona InfiniteFocus G5 to perform comprehensive 3D surface analysis at the nano level, providing detailed 2D Ra and 3D Sz surface roughness results with a resolution of 10 nm. This allows for the detection of any potential corrosion, burns, or surface defects, with all measurements traceable to ISO standards.

By utilising many groundbreaking techniques and expertise in micro machining to solve complex micro-manufacturing problems, at Micro Systems, significant progress is being made as we move from micro to nano manufacturing. With in-house mould design, mould manufacture and micro moulding capabilities, Micro Systems can provide one-stop solutions for challenging ultra-precision manufacturing projects for medical, pharmaceutical, ophthalmics and diagnostics markets.

Contact us today to discuss your Mould Manufacture and Injection Moulding projects!

Micro Systems (UK) Limited

As posted on »inno« No. 85: High-Precision Production Processes