Overmoulding in Medical Devices: Enhancing Biocompatibility & Durability

Overmoulding, also known as two-shot or 2K injection moulding, is a precise manufacturing process where a secondary polymer, often an elastomer or silicone, is moulded over a substrate, creating a seamless, high-performance medical component. It enhances biocompatibility, durability, and user safety, while eliminating adhesives and reducing assembly complexity.

1. Biocompatibility: Safe contact with patients

- Medical-grade elastomers, including liquid silicone rubber (LSR) and thermoplastic elastomers (TPE/TPU), offer hypoallergenic surfaces suitable for direct skin and tissue contact.

- These materials comply with ISO 10993 standards and withstand sterilisation techniques including autoclaving and gamma irradiation.

- Seamless overmoulding reduces potential microbial ingress by eliminating sharp edges and assembly joints.

2. Durability: Built for long-term clinical use

- Overmoulded medical devices resist aggressive disinfectants, solvents, and mechanical abrasion, maintaining performance across multiple sterilisation cycles.

- Silicone-overmoulded connectors can endure up to 500 autoclave cycles at 134 °C without degradation in adhesion or flexibility.

- Integrated elastomeric layers act as vibration dampers, increasing impact resistance and improving patient and clinician safety.

3. Functional & ergonomic benefits

- Soft-touch interfaces, non-slip grips, and visual coding improve surgical instrument handling and user comfort (Medical Design Briefs, 2024).

- Multi-material integration enhances sealing performance for fluid-handling devices, reducing leakage risks in critical applications.

- Production efficiency improves by reducing assembly steps and minimising adhesive use.

4. Material & design engineering considerations

- Robust adhesion requires careful matching of substrate and overmould materials (e.g., PEEK with TPE or polycarbonate with LSR).

- Surface treatments such as plasma etching or chemical priming may be applied to enhance interfacial bonding (Medical Design Briefs, 2024).

- Differential shrinkage and thermal expansion must be accounted for to maintain medical-grade tolerances.

5. Regulatory and technical requirements for overmoulding medical devices

Overmoulding medical components demands strict adherence to regulatory, material, and process requirements to ensure patient safety and product compliance. Materials must be certified as medical-grade and comply with ISO 10993 for biocompatibility, particularly where direct or indirect patient contact occurs. The process should be validated according to ISO 13485 standards, incorporating traceability, risk analysis (ISO 14971), and cleanroom manufacturing where required. Additionally, the overmoulding process must withstand repeated sterilisation cycles, such as steam autoclaving, ethylene oxide (EtO), or gamma irradiation, without degradation of mechanical properties, adhesion strength, or dimensional stability. Design engineers must also account for chemical resistance to hospital disinfectants, compatibility between substrate and overmould materials, and mechanical interlocks or surface treatments to ensure a robust and long-lasting bond.

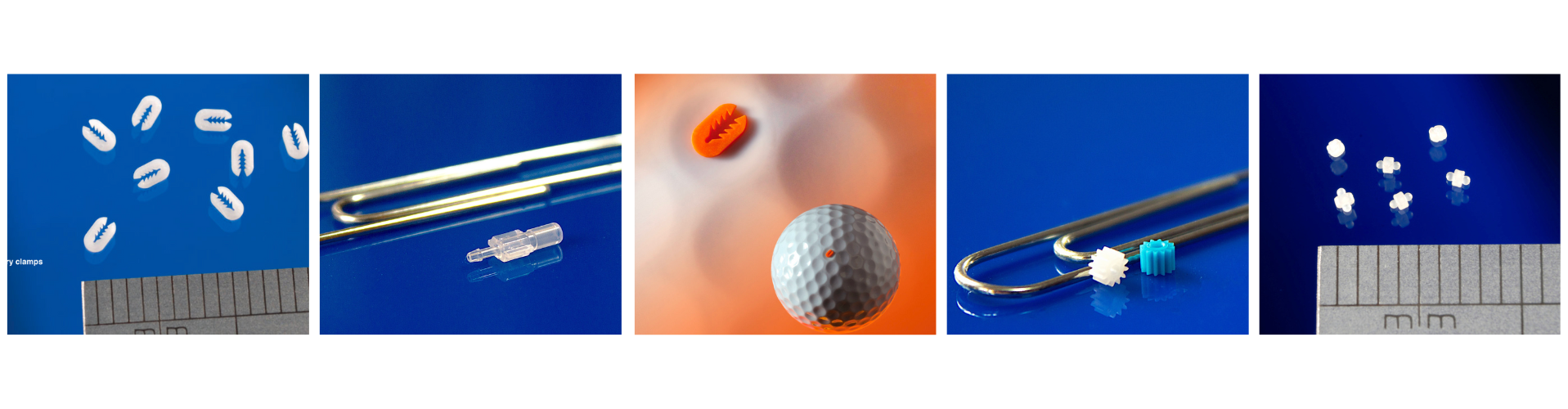

Micro Systems’ overmoulding expertise

Micro Systems specialises in precision overmoulding services for medical components, offering ISO 13485-certified manufacturing that integrates micro injection moulding with advanced overmoulding processes. Using Class 7 cleanroom facilities and validated process controls, Micro Systems ensures full regulatory compliance, biocompatibility testing, and scalable production for high-volume medical device programmes (Micro Systems, 2024).

Contact us today!