Breakthroughs in Micro Injection Moulding with Wittmann MicroPower Micro Moulding machines

The demand for complex micro moulded parts

Small parts with extremely tight accuracy and tolerances are commonly in demand in a number of markets, including the Medical/Healthcare industry, Electronic industry, Automotive industry, Telecommunication industry and so many more. With the rapid development of technology and miniaturisation trend, the micro injection moulding market expects an exponential growth with new applications to be applied in new industries that have not yet been explored, with a predicted market value to reach more than 2.6 billion USD by 2030 (source).

Within the medical industry, micro injection moulding is extremely useful in manufacturing complex parts of 1 or more materials, in large quantities, within a clean-room environment. Over the coming years, the market is expected to grow as a result of an increase in the usage of sophisticated micro components for endoscopic surgery, a rise in the demand for minimally invasive treatments, and the desire to make implants and medical devices more comfortable for patients. There are also increasing demands for point-of-care testing and personalised medicine, leading to recent advances in the production and application of products like lab-on-a-chip.

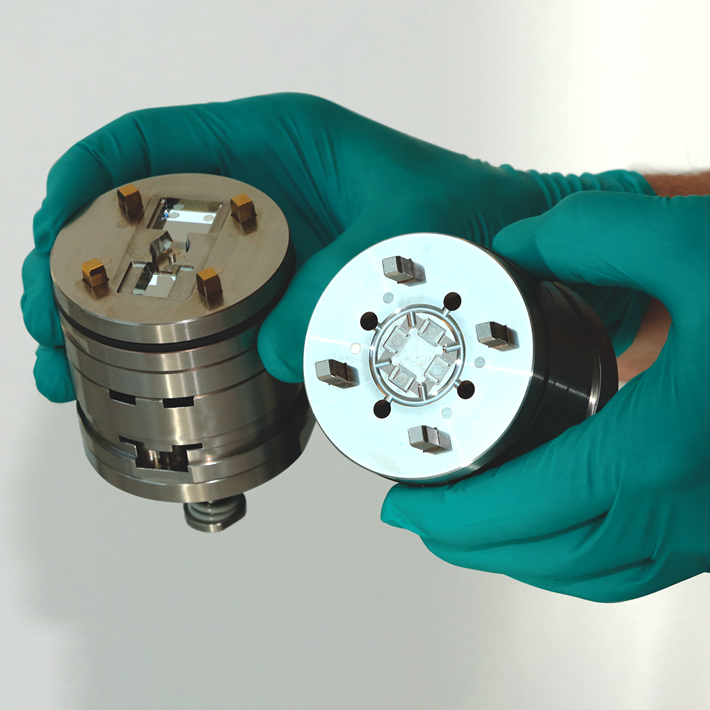

Photo: Using Wittmann Battenfeld MicroPower 15 machines helps Micro Systems achieve micro and nano features on multiple medical device components.

The ultimate micro injection moulding technology

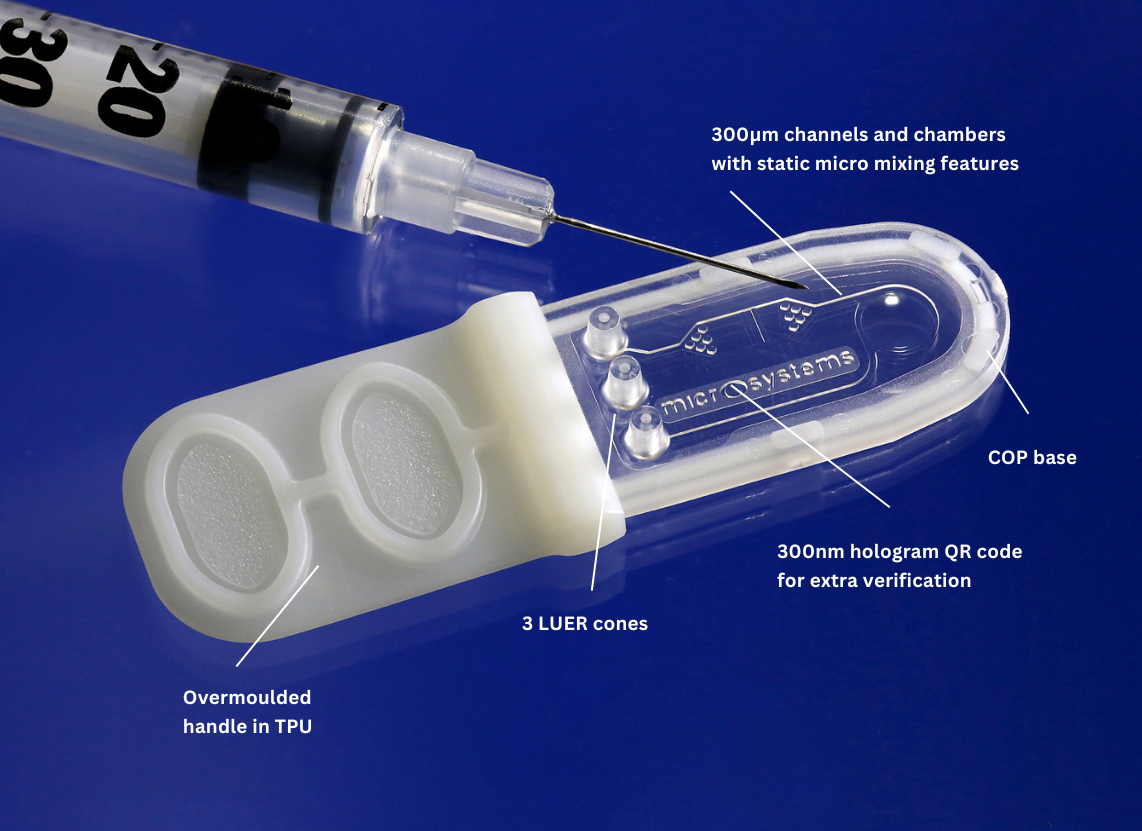

Using one of the most sophisticated micro injection moulding machines on the market with our in house manufactured ultra-precision moulds, Micro Systems has achieved significant breakthroughs in moving from micro to nano manufacturing. For example, the Wittmann Battenfeld MicroPower 15 machines has an impressive capability in manufacturing our lab-on-a-chip devices, with extremely high degree of precision for micro parts and micro surface structures throughout a stable injection moulding process. This lab-on-a-chip sample has a base plate with 300 μm-micro channels and chambers with static micro mixing features, and 3 LUER cones on the top part. The production of this 2-component application is carried out in an ISO 13485 accredited clean-room micro injection moulding environment, ensuring the final products meet global strict medical requirements. Using our trusted Wittmann Battenfeld MicroPower 15 machines, we are able to achieve more complex applications in microfluidics and lab-on-a-chip manufacturing, where microfluidic features required for the manipulation of capillary flow to generate specific capillary requirements (filling, pinning or mixing), and microfluidic junctions required for droplet mixing and generation are precisely reproducible within 0.5 microns.

Photo: Micro Systems’ microfluidics chip using a multistage-2-component injection moulding on Wittmann Battenfeld MicroPower 15 machines. The manufacturing cell originally consisted of two micro injection moulding machines connected together via a cleanroom tunnel, then now simplified due to the development of the 2-shot MicroPower 15 machines. The now ready for use lab-on-a-chip can be inserted into a hand carried measuring instrument, for example for the execution of a drug test with blood or urine.

Besides, utilising the advanced technologies of Wittmann Battenfeld MicroPower 15, Micro Systems have successfully manufactured lenses with in-line inspection capability used to accept or reject lenses based on the detection of particulates of less than 5 micron in diameter within the lens area. Other products manufactured in-house using our Wittmann Battenfeld MicroPower 15 machines include micro check valves with critical sealing diameters to seal mist passage in soft-mist inhaler, micro cannulas for precision medicine delivery, etc.

The use of Wittmann Battenfeld MicroPower 15 machines also supports Micro Systems in manufacturing high-precision micro parts from engineering plastics including POM and PEEK, with high-precision reproduction of micro structures inside the mould, for example, Fresnel lenses and copyright protection holograms. Wittmann Battenfeld MicroPower 15 machines also allow for combi-mould of two or more plastic materials in different colours or with different attributes and insert moulding (using a high precision handling robot and a metal parts feeding station), helping us stay ahead in this competitive market.

Photo: Wittmann Battenfeld MicroPower 15 machines in ISO class 7 cleanroom at Micro Systems in the UK.

Reflecting on the outstanding performance of Wittmann Battenfeld MicroPower 15, Tom Clark, Technician at the micro moulding department at Micro Systems said, “The Micropower 15 machines are really impressive to work with. The excellent user-friendly interface makes it very easy to operate efficiently. They are always consistent and reliable in providing excellent repeatability as well as low cycle times. The use of integrated camera systems to check components during production is very beneficial and time saving for us. We have achieved impressive results in moulding complicated components with small features thanks to the Micropower 15”.

Micro Systems in-house micro-mould manufacture and processing knowledge, combined with the outstanding performance and process control of Wittmann Battenfeld MicroPower 15 machines, enable us to accurately produce micro moulded components which push the boundaries of micro-engineering and would previously have been considered impossible. The combination of technology and knowledge allows for efficient turnkey capabilities, from micro mould design, micro mould manufacture to customised micro injection moulding.

For further information, contact Micro Systems today to discuss your micro injection moulding projects!