Top Medical-Grade Plastics for Injection Moulding: From PEEK to TPE

In the evolving field of medical device manufacturing, medical injection moulding continues to lead in precision, sterility, and scalability. The performance of a medical product is heavily influenced by the polymer it’s made from, especially when dealing with implantable, biocompatible, or sterilisation-resistant parts. This article covers the most advanced and reliable materials used in British injection moulding, from PEEK to TPE, with attention to mechanical behaviour, process parameters, and medical compliance.

1. PEEK (Polyether Ether Ketone)

PEEK is a semi-crystalline, high-performance thermoplastic from the polyaryletherketone family. Its outstanding mechanical and thermal properties make it suitable for long-term implants and load-bearing applications in medical moulds.

Key Properties:

- Tensile strength: ~90–100 MPa

- Modulus of elasticity: ~3.6 GPa

- Melt temperature: ~343°C

- Sterilisation: Compatible with autoclave, gamma, EtO, and steam

- Biocompatibility: Certified to ISO 10993 and USP Class VI

In British injection moulding operations, PEEK is used for spinal cages, dental frameworks, and cardiovascular devices due to its radiolucency and chemical resistance [Victrex, 2024]. Processing requires precise control of melt and mould temperatures (360–400°C barrel, 160–200°C mould) and corrosion-resistant tooling [Smith & Nephew, 2023].

2. TPE (Thermoplastic Elastomers)

TPEs are versatile materials that behave like elastomers but can be processed using thermoplastic methods. They are ideal for soft-touch, flexible medical components.

Key Properties:

- Shore hardness range: A20 to D50

- Elongation at break: Up to 600%

- Sterilisation: EtO, gamma (autoclave tolerance depends on type)

- Biocompatibility: ISO 10993 certified

TPEs are widely used in wearable medical devices, syringe grips, catheter seals, and fluid control valves. In British injection moulding, medical-grade SEBS- and TPU-based TPEs are commonly overmoulded onto rigid substrates using multi-shot or insert moulding techniques [British Plastics Federation, 2024].

3. Polycarbonate (PC)

Polycarbonate provides a combination of transparency, impact resistance, and dimensional stability. It is widely used for diagnostic housings, IV chambers, and filter components.

Technical Features:

- Tensile strength: ~70 MPa

- Glass transition temperature: 147°C

- Sterilisation: EtO, gamma, limited autoclave cycles

PC requires pre-drying at 120°C for 4–6 hours to prevent hydrolytic degradation during processing. Medical-grade variants are manufactured under strict quality control for use in Class II and III devices [Covestro Medical Polymers, 2023].

4. Polypropylene (PP)

PP is a semi-crystalline polymer valued for chemical resistance, steam sterilisability, and low cost. It is commonly used for non-implantable disposables such as syringes, pill containers, and labware.

Properties:

- Melt flow index: Varies by grade (typically 12–25 g/10min)

- Sterilisation: EtO, gamma, autoclave

- Fatigue resistance: Excellent (ideal for living hinges)

Its low melt viscosity makes it suitable for thin-wall moulding with short cycle times in high-volume medical injection moulding lines [MHRA, 2023].

5. Polyethylene (PE)

Medical-grade polyethylene, including HDPE and UHMWPE, is widely used in tubing, prosthetic liners, and orthopaedic implants.

Features:

- Coefficient of friction: Exceptionally low

- Tensile strength (HDPE): ~30 MPa

- Sterilisation: EtO and gamma

UHMWPE, in particular, is used in acetabular cups and knee bearings due to its outstanding wear resistance and low particulate generation. It is more commonly machined than injection moulded due to high viscosity [Zimmer Biomet, 2022].

6. ABS (Acrylonitrile Butadiene Styrene)

ABS offers good rigidity, impact resistance, and ease of processing. It is used for housings, hand-held instruments, and non-invasive diagnostic devices.

Characteristics:

- Heat deflection temperature: ~95°C

- Surface finish: High gloss, paintable

- Sterilisation: EtO and gamma (not suitable for steam)

ABS is rarely used in implantables but is suitable for electronic and structural enclosures. It is processed in British injection moulding environments requiring cosmetic appearance and moderate durability [BASF Healthcare, 2023].

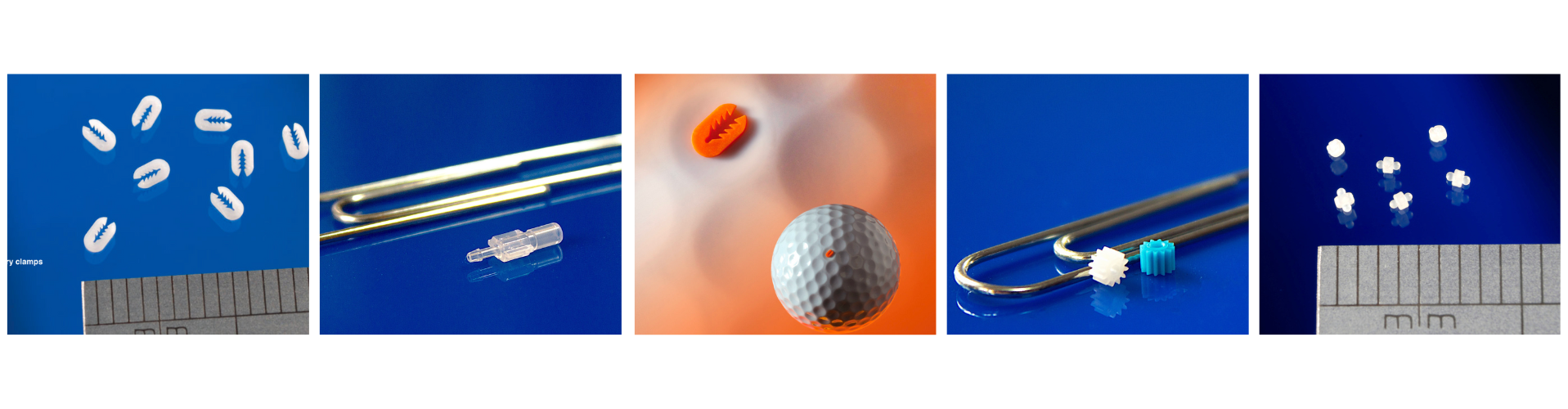

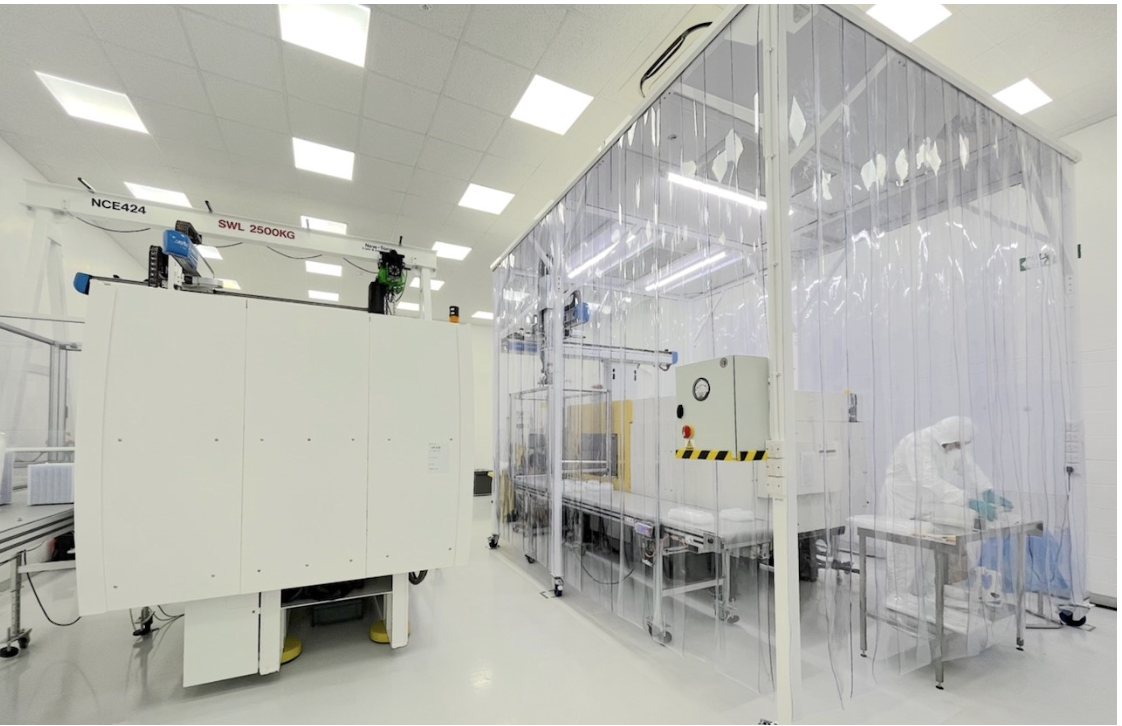

Mould Design and Cleanroom Processing

Medical moulds used in Class II and III device manufacturing must be built to exacting tolerances (±0.01 mm or better). Tooling typically uses corrosion-resistant grades such as 420 stainless or H13, with SPI A2 or A3 surface finishes to allow for smooth part release and minimal particulate generation.

Many British injection moulding manufacturers operate ISO Class 7 or 8 cleanrooms to support sterile production lines. Mould validation (IQ/OQ/PQ), material traceability, and device history records are required to meet MHRA and UKCA standards [GOV.UK, 2024].

The selection of the right polymer for medical injection moulding is a complex balance between mechanical performance, sterilisation resistance, processing behaviour, and regulatory compliance. From the structural robustness of PEEK to the flexible biocompatibility of TPE, British injection moulding specialists rely on a core portfolio of medical-grade thermoplastics to meet industry demands.

Each of these materials—PEEK, TPE, PC, PP, PE, and ABS—plays a unique role in the design and function of modern medical devices. The correct application of these plastics, combined with well-engineered medical moulds, ensures compliance, patient safety, and long-term product success.

Contact Micro Systems today to get support from our medical moulding experts!