Sustainability in medical plastics

The problems of plastics

Years after years, people have been talking about the problems of plastics, with serious consequences touching all aspects of life. It is believed that 9 billion tonnes of plastic have been produced since the 1950s, when industrial production began, but just around 9% of that output has ever been recycled. In the previous 3 decades, plastic manufacturing has quadrupled, with more than 380 million tonnes of plastic produced globally in 2020. Despite rising recycling rates, only 16% of plastic trash is recycled to generate new plastics, with the remaining 40% going to landfill, 25% incinerated, and 19% dumped. Other studies suggest that up to 22% of all plastics waste escape and enter the environment uncontrollably, with severe repercussions. According to the World Health Organization, approximately 80% of hospital trash is general garbage, 55% of which is plastic with a recycling rate of 20%.

In the healthcare industry, plastic waste often consists of both clinical and non-clinical materials. Gloves, protective garments, surgical drapes, syringes, incontinence products, and IV bags & administration kits are examples of significant product categories for clinical goods in a hospital context. Food-contact items, hygiene supplies and bags are examples of non-clinical waste.

Due to its nature, medical plastic waste raises serious issues in the amount generated and its treatment. Annually, the usage of plastics in healthcare was recently projected to be 15 million tonnes globally, and account for 36% of healthcare waste in Europe. Furthermore, 42% of healthcare plastic waste is burnt, resulting in climate change and environmental consequences. In particular, in the UK, the NHS, one of the largest generators of healthcare waste in Europe, is the largest consumer of single-use plastics. According to a recent assessment by Healthcare Without Harm, the NHS created 11,300 tonnes of trash every day before the epidemic, 22.7% of which (or almost 2,500 tonnes) are plastic waste daily.

Plastics are used commonly in hospitals in a number of ways, from throwaway plastic syringes to surgical instruments. Especially, single-use plastics are seen as an appealing choice in healthcare since they allow for the preservation of a sterile environment and the easy disposal of any diseased plastic material. However, the sheer volume of single-use plastics used in hospitals is worrying, which is why hospitals must implement methods to support the decrease of single-use plastics in the future.

The future of sustainability in medical plastics

With revolutionary changes in technology, the medical plastics sector has a great potential to promote sustainability from product conception to product end-of-life for both disposable and durable devices and equipment. In 2020, the NHS (UK) unveiled its “For a Greener NHS” campaign, which seeks to dramatically reduce the healthcare system’s carbon footprint and plastic waste output in order to become the world’s first net zero healthcare system.

Current methods of incineration, landfill, and low-value recycling must be replaced with a “circular” mindset in which everything is created, acquired, and utilised for as long as possible at its best value before being recycled back into new goods or other high-quality applications. While it is almost impossible for the healthcare industry to achieve net-zero emission plastics status due to the importance of single-use plastic in preventing contamination and infection spread, it is possible, and more important than ever, for the industry to minimise plastic consumption and waste in certain areas.

Reduce plastic usage

Among the three R’s of Sustainability, reducing is considered to be the most effective in tackling our waste issues, and it can happen at all aspects within the healthcare industry.

For example, the NHS (UK) is committed to cut up to 100 million plastic straws, cups and cutlery from hospitals, as the organisation purchased at least 163 million plastic cups, 16 million pieces of plastic cutlery, 15 million straws and 2 million plastic stirrers in 2018 alone.

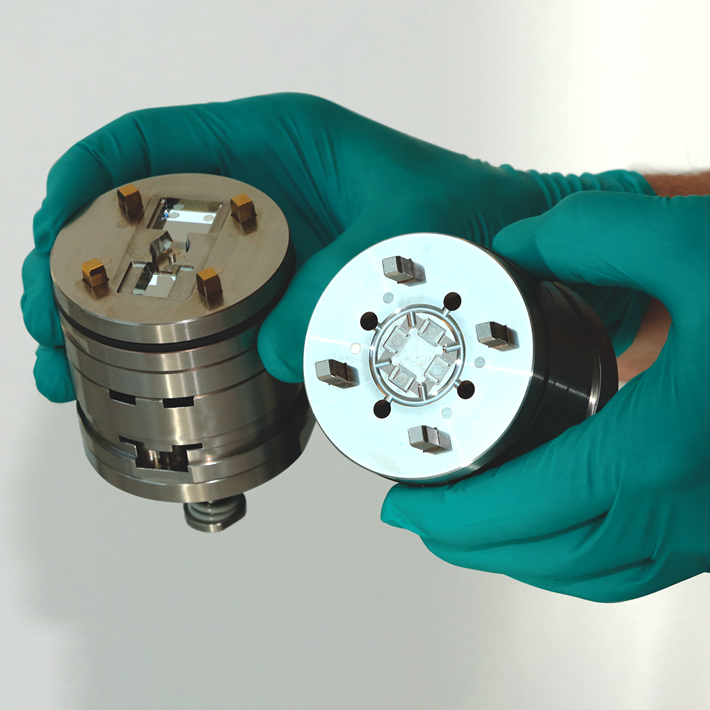

Surgical Innovations provides a range of reusable instruments, for example, reusable trocar reusable cannula, which help hospitals reduce costs and waste (up to 70% compared to costly, fully disposable alternatives) while ensuring its reliability and quality.

Replace where possible

Beside reducing single-use plastic consumption in seem-to-be easier areas like catering and packaging, hospitals worldwide are renovating their way of doing things, replacing traditional single-use plastic items with reusable, long-lasting ones. For example, the NHS (UK) now uses reusable sharps containers which could be re-used up to 600 times, saving 600 single-use containers from being incinerated (equivalent to running 2 small cars for a year), and lots of bulky packaging.

Another successful alternative is the FDA-approved Enviropouch, a reusable steam sterilisation pouch designed to replace single-use plastics used to keep sanitary requirements up to date. Or NewGen Surgical with their plant-based skin stapler, which saved 500 pounds of plastic waste on every 10,000 staplers used. Even though they are not yet widely used, these developments have acted as significant milestones toward sustainability in modern healthcare goods. New materials like PolyVinyl Chloride PVC have been effectively substituted in some medical foams, and material manufacturers are also looking at alternatives to animal-based gelatine.

Recycle

According to the Healthcare Plastics Recycling Council (HPRC), Europe creates around 1 million tonnes of non-infected medical plastic waste each year, which may be recycled. By effectively separating the waste stream at source in hospitals and healthcare centres, it is more achievable to increase the rate of recycling single-use plastic waste, especially ones that are not biohazards since they do not come in contact with patients and practitioners. Partnering with experts like HPRC could help hospitals set up and implement recycling programmes for medical plastic waste more effectively and economically.

Human factor

The human factor, on the other hand, is critical throughout the transformation to increase the sustainability of medical plastics. Continuous monitoring, as well as comprehensive education and awareness training, are required to guarantee that the right decisions are taken and implemented on a daily basis. According to a recent study, a long list of factors has contributed to the embedding of single-use practices and norms in US healthcare, including just-in-time purchasing systems to reduce storage, planned obsolescence from manufacturers and suppliers, the mistaken belief that re-used items impacts risk and patient safety, the concerns about purchasing liability and cost, the confusing classificatory and asymmetric regulatory frameworks and split roles and incentives for taking action (Transforming The Medical Device Industry: Road Map To A Circular Economy: Study examines a medical device industry transformation). Organisations like WRAP are helping hospitals across departments with tools and guidance widely available to relevant personnels.

Procurement wise, adopting a strategy that includes sustainability into the procurement process and considers environmental consequences from the start would assist healthcare systems in reducing wasteful single-use plastic.

Last year at COP26, 45 nations committed to more sustainable and low-carbon healthcare, with 14 aiming for net zero by 2050. Thus, innovations and revolutionary business ideas are crucial for plastic medical product providers, to both meet the changing demand of hospitals worldwide, and to achieve a more sustainable growth.

At Micro Systems (UK), our experts work closely with each customer to design and produce moulds for medical-grade components that meet the toughest requirements of the industry while celebrating innovative breakthroughs to improve the sustainability performance. We also welcome partnership with universities and researchers all over the world to develop new concepts and ideas related to micro and nano moulding. Our sustainability strategy and quality control support our customers in increasing their supply chain transparency and commitment towards sustainability in the healthcare industry. Contact us today to start planning your micro injection moulding project and take advantage of our decades of micro moulding expertise.

Check out our 2022 CSR Report!