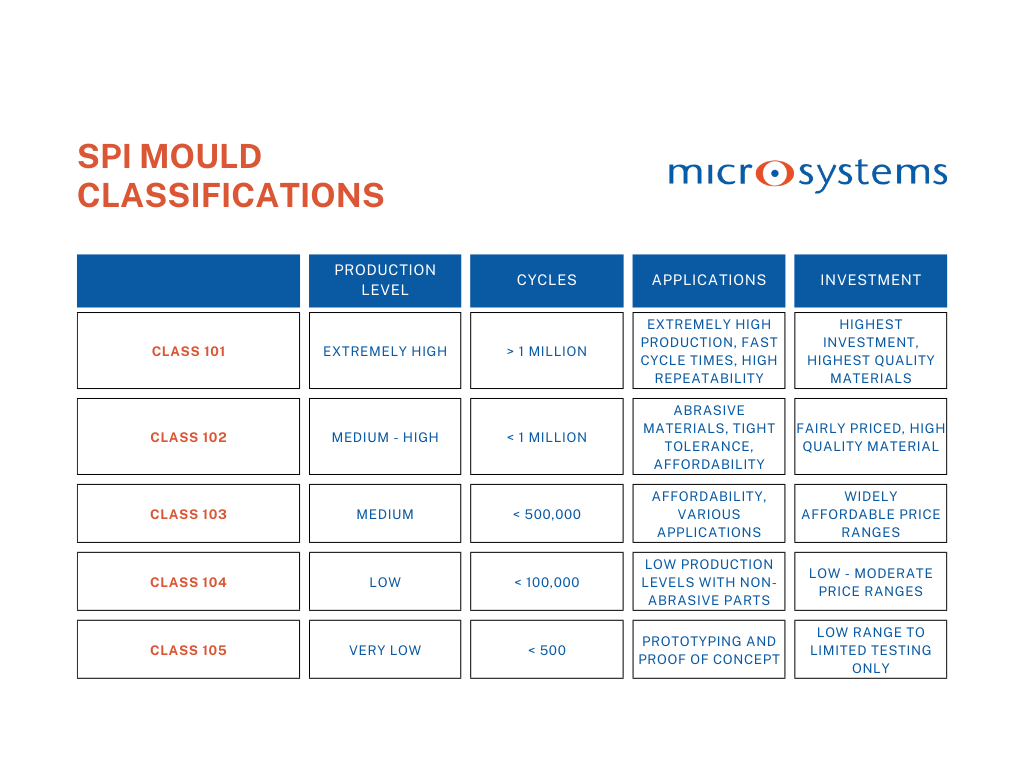

SPI Mould Classifications

SPI Mould Classifications offers a standardised method for categorising moulds. The standard includes class 101 through class 105, with class 102, 103, and 104 moulds comprising the majority of moulds now in production.

What is SPI Mould Classifications?

The Society of the Plastics Industry created the SPI Mould Classifications in an attempt to provide a more straightforward explanation of the kind of thermoplastic injection tool needed for a certain manufacturing need. These rules are meant to be only a guide, as they will often change when more projects are undertaken or as needed by the client, in order to better represent the needs of a certain tool. Distinctive distinctions in tool design, construction, materials, and components will be determined by the various categories. SPI includes 5 levels of classifications, from Class 101 to Class 105.

Class 101 Tool

Class 101 is used for high output moulds.These moulds are made using the best materials available, hence generally are the most expensive, guaranteeing lifespan and durability, and include features like sliding cores, gibs, and line locks. They are built to survive more than a million cycles and are intended for incredibly high productivity and fast cycle time. In order to maintain the integrity of the mould over time, tool steel with a minimum hardness that can withstand abrasive materials is frequently needed for these moulds.

Controlling the temperature is crucial for these moulds, especially for slides, cores and cavities. To maintain the mould’s temperature and guarantee constant component quality, there must be enough channels for heating and cooling. Cooling channel-containing plates and inserts should be made of corrosive-resistant material or coated to stop corrosion. Minimum hardness for the mould foundation should be 280 BHN, and cavities and cores used for moulding must be hardened to a minimum of 48 Rc range. Class 101 moulds are a reliable option for applications requiring great repeatability and tight tolerances.

Class 102 Tool

Class 102 moulds combine affordability and quality in a harmonious way. These moulds are made for applications requiring up to a million cycles and are appropriate for medium to high production volumes. They may not be as durable as Class 101 moulds, but they still have a remarkable lifespan. Often constructed from premium steel, the tooling for these moulds has a somewhat lower hardness than Class 101. The minimum hardness required for tool construction components is 28 Rc, and it is recommended to harden cavities and cores to a minimum of 48 Rc range. Whenever feasible, temperature control features should be located right inside the cavities, cores, and sliding cores. Class 102 moulds are a well-liked option for applications that need to strike a compromise between performance and affordability because of these mould qualities.

Class 103 Tool

Class 103 moulds are frequently the first option for manufacturers in the plastics sector searching for a dependable mould for medium production runs. The applications for which these moulds are intended can need up to 500,000 cycles. As they are made of high-quality materials, they should operate well without going over budget. The minimum hardness required for tool construction components is 18 Rc, and cores and cavities must have at least 28 Rc. Their non-abrasive material-specific requirements make them an adaptable option for a variety of applications.

Class 104 Tool

Class 104 moulds are useful when there are minimal production requirements and non-abrasive materials are being employed. For short runs, usually up to 100,000 cycles, these moulds are perfect. They are frequently produced of gentler steel varieties, which may not have the hardness of their higher-class counterparts but are nonetheless suitable for their intended purposes due to their restricted production scope. Aluminium, mild steel, or any other metal that is agreed upon can be used for cavities.

Class 105 Tool

Prototypes are vital in the early phases of product development. Prototype moulds, also known as class 105 moulds, are made for very limited manufacturing runs, usually less than 500 cycles. They are ideal for testing functionality and design ideas prior to going into full-scale production. These moulds may not have as many features as more advanced classes because of their restricted use, but they nonetheless accomplish their goal of creating the minimal number of prototype pieces required for testing. For this classification, all components are optional, hence designers and manufacturers have the full flexibility to test their concept.

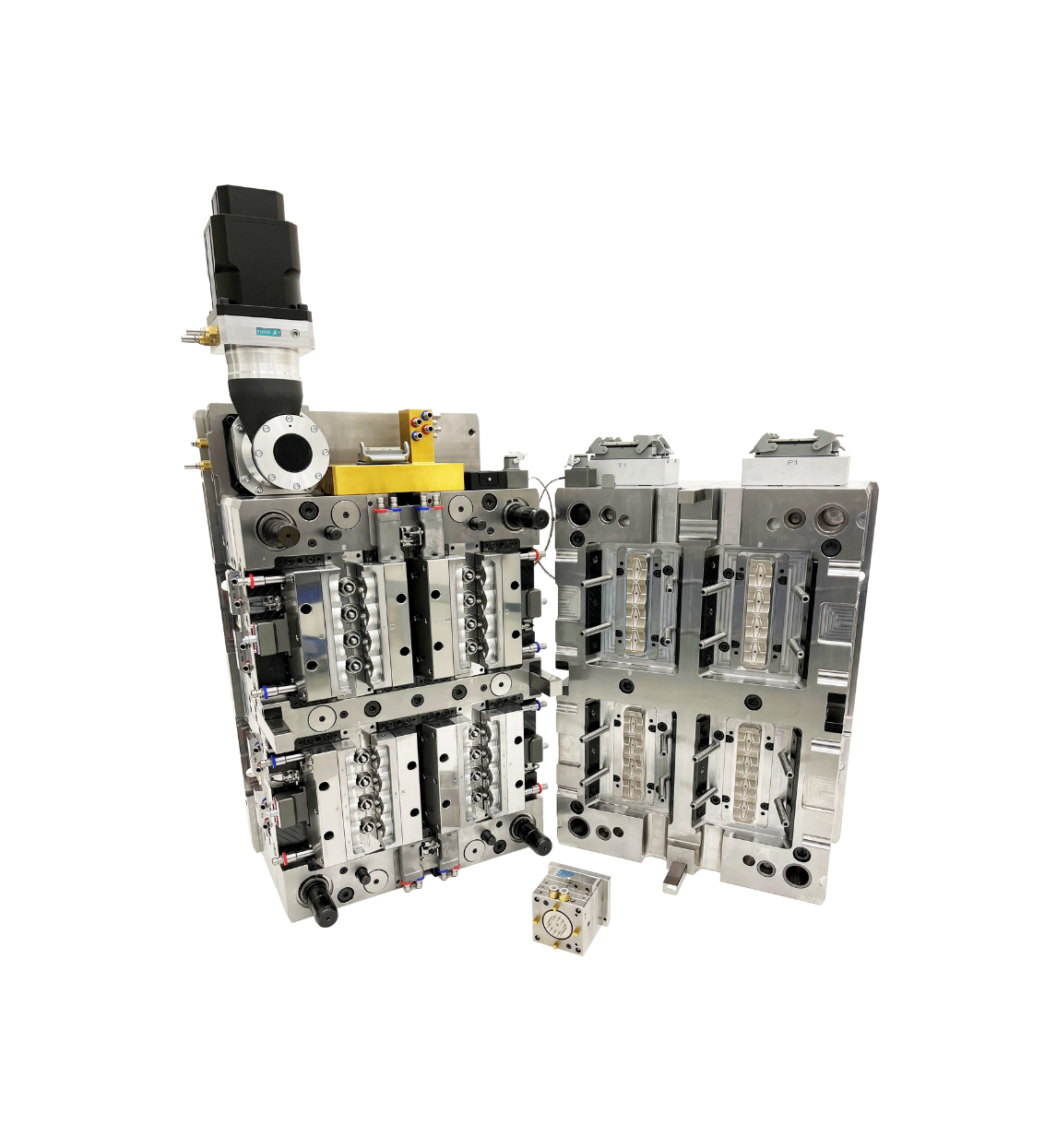

At Micro Systems, we have the extensive experiences and capabilities to design and manufacture all SPI mould classifications per request, with full support from day 1 of the project. We also have in-house the latest technology for machining, metrology and quality assurance. We are ISO 9001 and ISO 13485 certified.

Contact us today to discuss your mould and tooling projects!