Non-medical applications of Microfluidics

Microfluidics, the study of fluids on the micro- and nanometer scale, has now advanced to the point where a wide range of applications, in both medical and non-medical fields, may be served in various processes. The future research will be able to incorporate this technology into end products that can be used by both specialists and non-specialists, allowing for more effective and affordable applications.

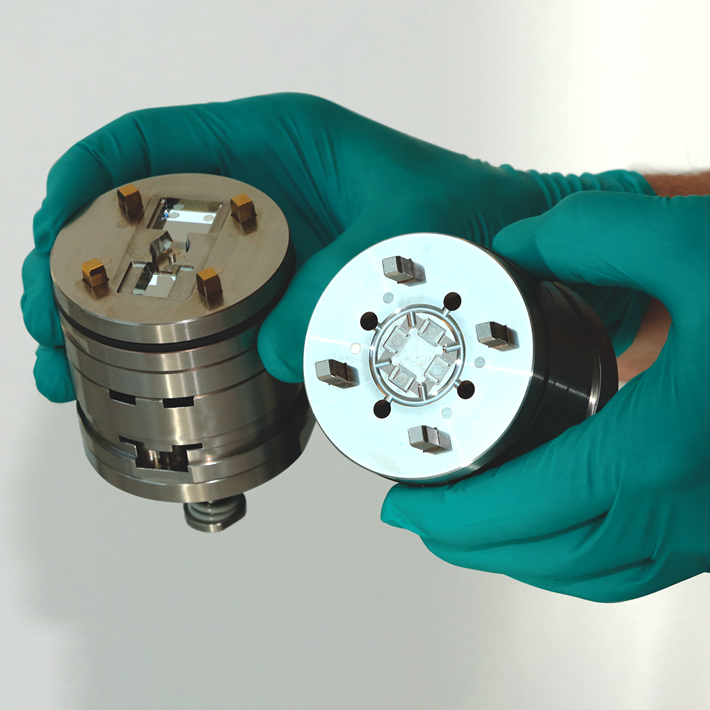

(Photo: Micro Systems)

Microfluidics and Environmental Applications

In the environmental sector, their primary uses include detecting water contaminants (e.g., heavy metals and organic pollutants), identifying microorganisms (e.g., viruses and bacteria), and studying environmental issues (e.g., bacterial electron transfer and biofilm formation) (Wang et al., 2020).

Microfluidics offers key advantages for water testing, enabling rapid, on-site analysis for real-time monitoring of pollutants and quick response to contamination. These devices can accurately test heavy metal levels and detect pathogens (e.g., bacteria and viruses) that cause waterborne illnesses, unlike traditional methods that are labour-intensive and generate significant waste. Recent advancements have made microfluidic platforms more affordable for monitoring contaminants in various water sources, including drinking, sewage, freshwater, and saltwater (Saez et al., 2021).

As water and sanitation is one of the UN’s goals for sustainable development, microfluidic technology enables on-site water quality testing without the need for expensive lab access or experts. It offers rapid analysis at remote locations, with enhanced sensitivity, selectivity, and reproducibility, resulting in shorter measurement times.

Another interesting application of microfluidics in the environmental field is soil analysis. The EU-funded MobiLab project created a lab-on-a-chip sensor that measures soil levels of the four most crucial plant nutrients: ammonia, nitrate, phosphate and potassium. Overfertilisation leads to excessive costs, groundwater pollution, greenhouse gas emissions, and depletion of natural fertiliser. Microfluidic-based soil analysis, replacing traditional methods, offers a quicker, cost-effective solution to sustain plant production while reducing environmental impact. Researchers have developed a capillary electrophoresis-based soil analyser that provides rapid, accurate macronutrient content indicators. By combining soil nutrient analysis with a single microfluidic chip, the iMETOS MobiLab analyser lowers expenses, according to project organiser Günther Kriechhammer. The project relies on creative engineering, including microfluidics, the science of manipulating and directing fluids through networks of channels with diameters ranging from tens to hundreds of micrometres, due to the structures’ micrometre scale.

Microfluidics and Energy Applications

Thanks to the extremely small dimensions of the capillaries in the microfluidic reactors and the associated high surface-to-volume ratio, microfluidic technology offers a way to get around some of the most significant shortcomings of the current techniques for synthesising nanomaterials. These traits enable quick and uniform mass transfer as well as better control over the properties of the created nanomaterials, at the same time, the compact size and distinctive geometries of such microreactors allow for fine fluid mixing control, enhanced heat transmission, simple automation, and significantly faster reaction times.

Another breakthrough research is in energy saving. A platform developed by the University of Toronto Engineering team, inspired by the colour-changing skin of squid, offers greater control and lower costs than previous methods. The prototypes, made of flat plastic sheets with millimetre-thick tubes, allow fluids containing customised pigments or particles to regulate light wavelength, intensity, and dispersion. This multi-layered fluidic system is designed to reduce energy costs in HVAC and building lighting.

Microfluidics and the Oil/Gas industry

The Oil and Gas industry is exploiting a number of microfluidics’s advantages, including but not limited to rapid analysis, low reagent volumes, low cost, excellent control of conditions, and opportunities for separations and multiplexing, both above and below ground. Furthermore, due to the extremely tiny volumes (and small areas) involved, high pressures with microfluidics are readily managed in contrast to conventional big pressure/volume/temperature cells. Microfluidics can be used for oil and gas analysis, property measurement, enhanced oil recovery and hydraulic fracturing.

A PhD researcher from the University of Aberdeen also came up with a revolutionising idea that will enable businesses to assess oil samples on-site. The technology has the potential to provide significant cost and time benefits across a wide range of businesses by eliminating the need to ship samples back to labs onshore.

Microfluidics technology is also ideal for removing crude oil from porous rocks that has been combined with contaminants or is in a dynamic condition.Crude oil extraction often requires rapid adjustments, necessitating the characterisation of fluid flow through porous rock to optimise resource extraction. Factors such as connectedness, tortuosity, and the interactions between fluid and pore structure influence this process. A microfluidic device can measure asphaltene content within 30 minutes, with a concentration range of 0.1% to 15%.

Microfluidics and the Food industry

Microfluidics is poised to revolutionise the food industry, enabling applications such as fish oil encapsulation, antibiotic detection in dairy, novel food structures, and pathogen monitoring in food and water (Neethirajan et al., 2011). It also offers significant benefits in agriculture and animal sciences, including nutrient monitoring, plant cell sorting to improve crop quality, biopesticide delivery, and enhanced animal breeding, health monitoring, vaccination, and therapeutics (Neethirajan et al., 2011).

For example, the MOLOKO project aims to manufacture, put into use, and validate a self-managing, automatic, miniature integrated photonic sensor that will be used as process analytical instrumentation for fast-response, on-site monitoring of interest analytes for security and quality within the milk supply chain. By implementing a highly-integrated optoplasmonic-microfluidic sensor in the strategic checkpoints along the entire supply and value chain of milk, the project specifically aims to realise multiplexing quantitative detection of up to 10 analytes, including food safety parameters such as antibiotics (e.g. penicillin, ampicillin, cephalonium) and toxins (e.g. mycotoxins and bacterial toxins) and food quality parameters such as lactoferrin and caseins.

Microfluidic applications are advancing rapidly in monitoring the safety and quality of packaged food, including time-temperature indicators, critical temperature sensors, food microbe detectors, and active packaging. Smart packaging technology, offering more than just protection, could shape the future of food packaging (Pou et al., 2022).

References:

Wang, T., Yu, C. and Xie, X. (2020) ‘Microfluidics for environmental applications’, Microfluidics in Biotechnology, pp. 267–290. doi:10.1007/10_2020_128.

Saez, J. et al. (2021) ‘Microfluidics and materials for Smart Water Monitoring: A Review’, Analytica Chimica Acta, 1186, p. 338392. doi:10.1016/j.aca.2021.338392.

Neethirajan, S. et al. (2011) ‘Microfluidics for Food, agriculture and Biosystems Industries’, Lab on a Chip, 11(9), p. 1574. doi:10.1039/c0lc00230e.

Pou, K.R.J., Raghavan, V. and Packirisamy, M. (2022) ‘Microfluidics in smart packaging of foods’, Food Research International, 161, p. 111873. doi:10.1016/j.foodres.2022.111873.

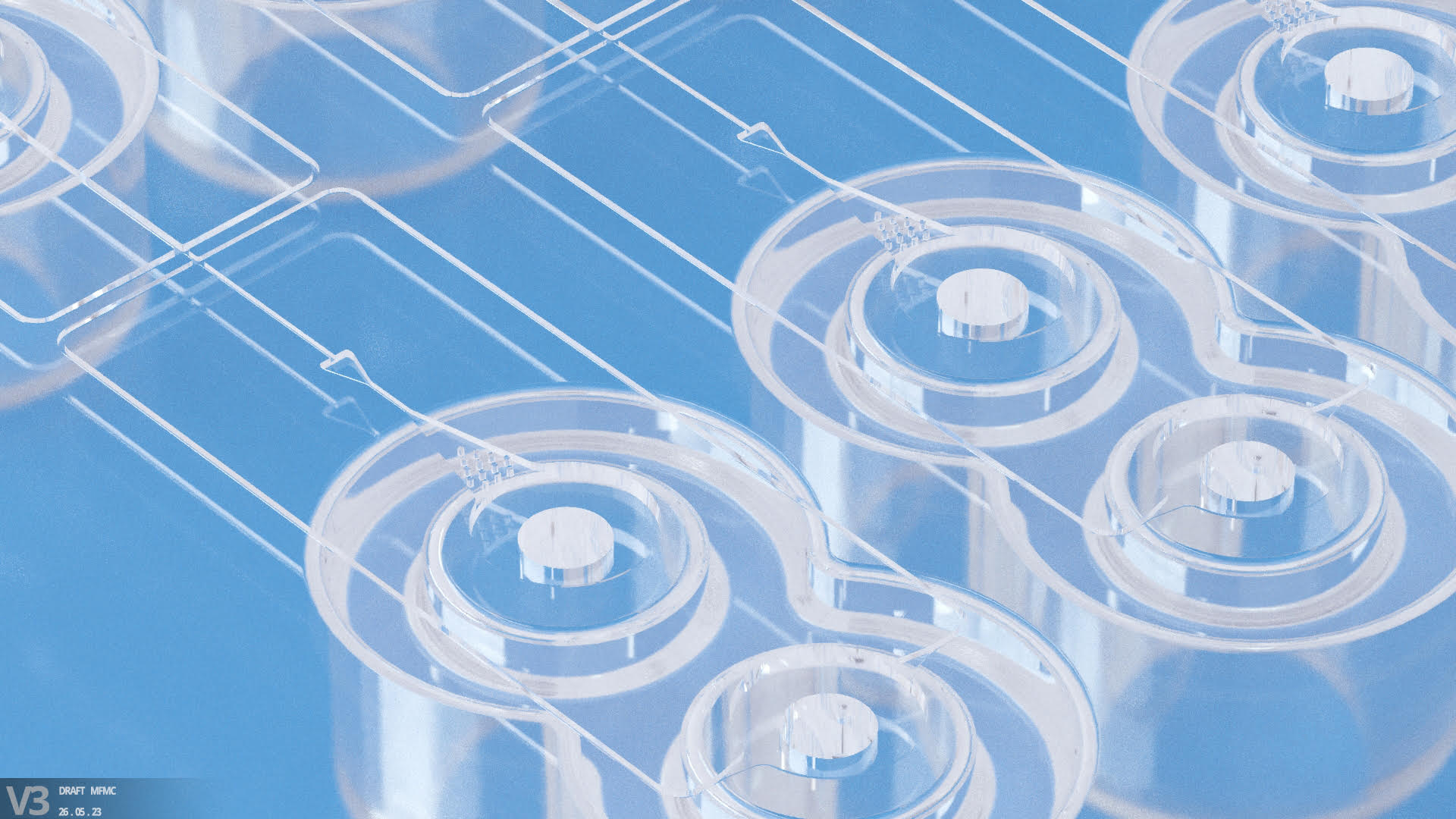

Micro Systems’s vast know-how in design, ultra-precision micro machining capabilities and expert knowledge in micro moulding technology allow us to manufacture advanced microfluidic moulds with tolerance as low as +/-0.001mm, with integrated optics. We have a dedicated micro moulding facility, and have ISO13485 and ISO9001 certifications. For more information, please Contact us or visit our website.