Microfluidics and its applications

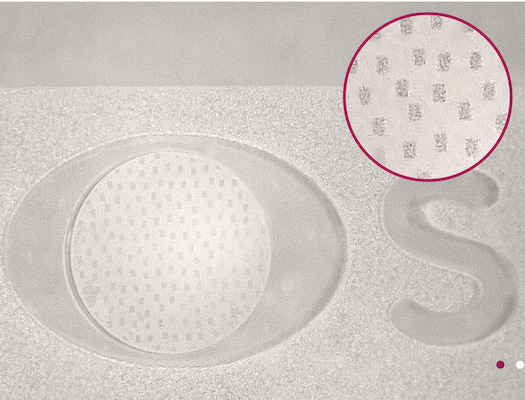

Lab-on-a-chip with 300 μm micro channels and chambers with static micro mixing features, and 3 LUER cones (Photo: Micro Systems)

What is Microfluidics?

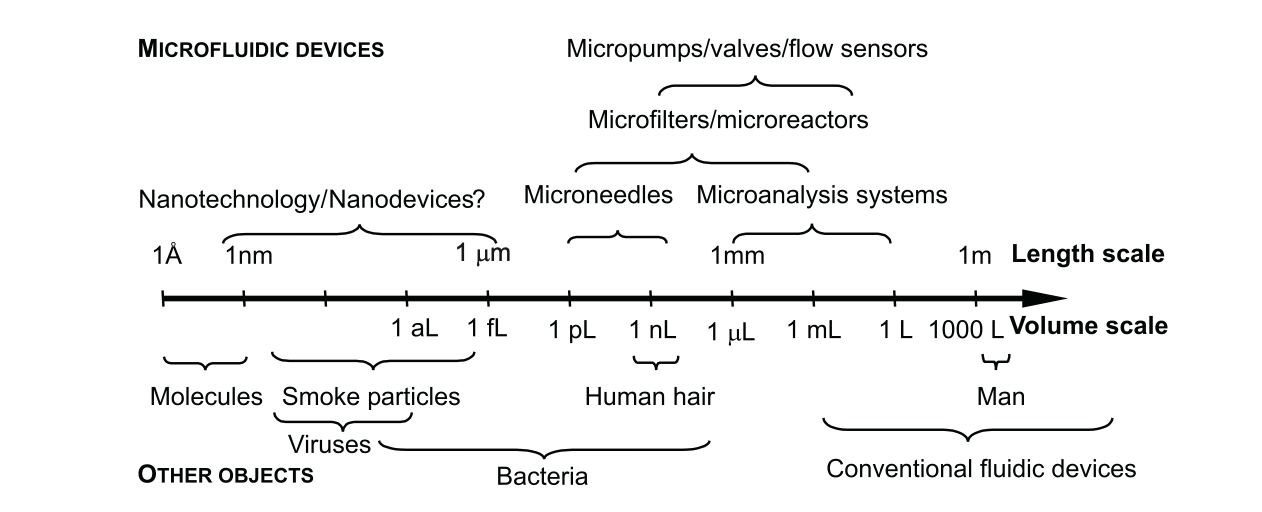

Microfluidics could be defined as the science and engineering of systems in which the behaviour of fluid is different from conventional flow theory mainly due to the small length scale of the system (Nguyen et al., 2019). The precise control and manipulation of tiny amounts of fluid within devices of internal diameters ranging from around 1 to 1000 micrometres could be achieved with microfluidics.

Microfluidics is not a field of engineering, science, or the creative arts, but actually a compilation of cooperative efforts that interdisciplinary engineers and scientists have made possible. It combines the profound knowledge within the field of the physics of fluids, at the same time, the engineering and expertise of designing and manufacturing devices with extremely small features.

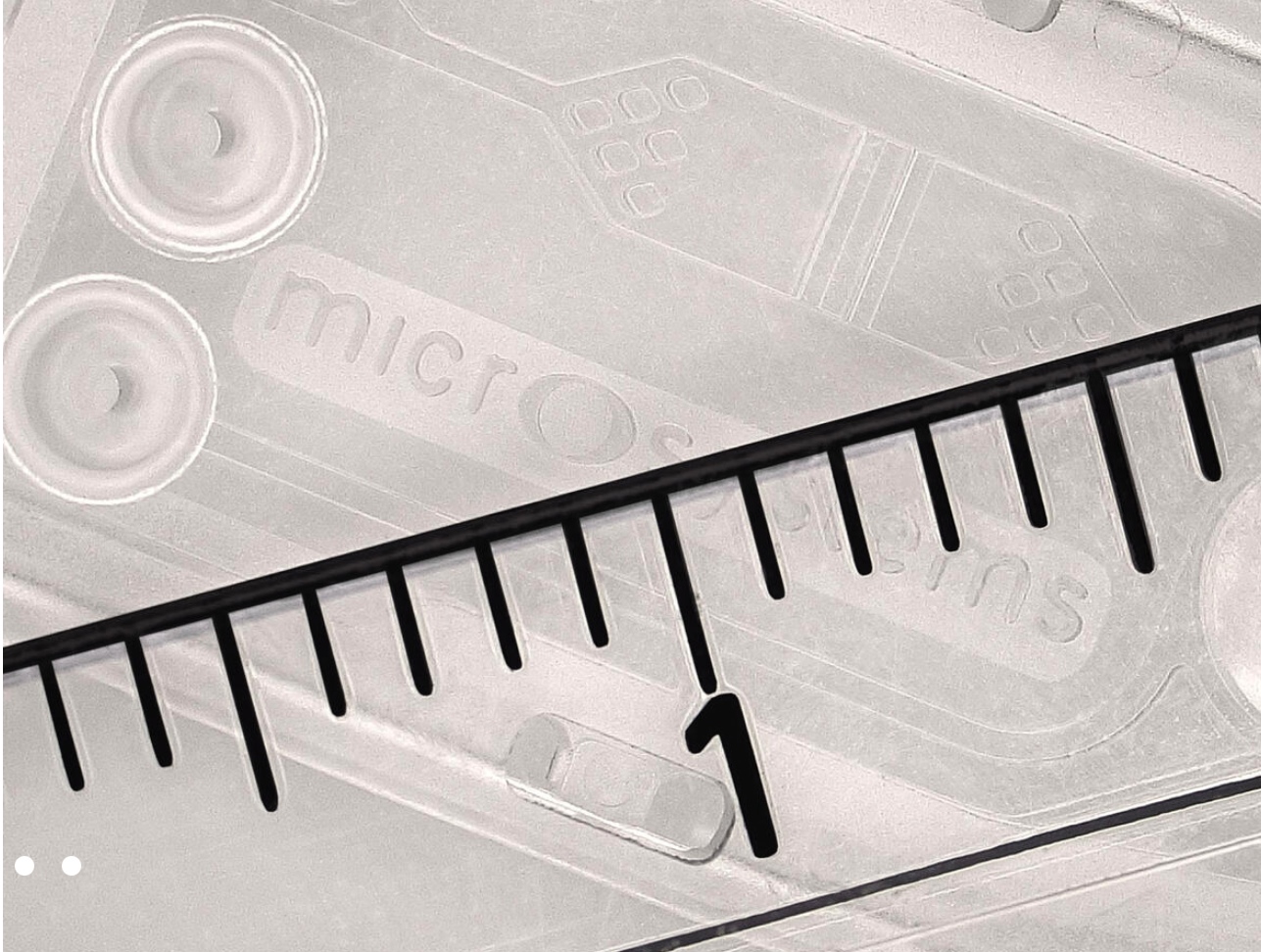

Microfluidic device sizes vary greatly depending on their applications (Photo: Nguyen et al., 2019)

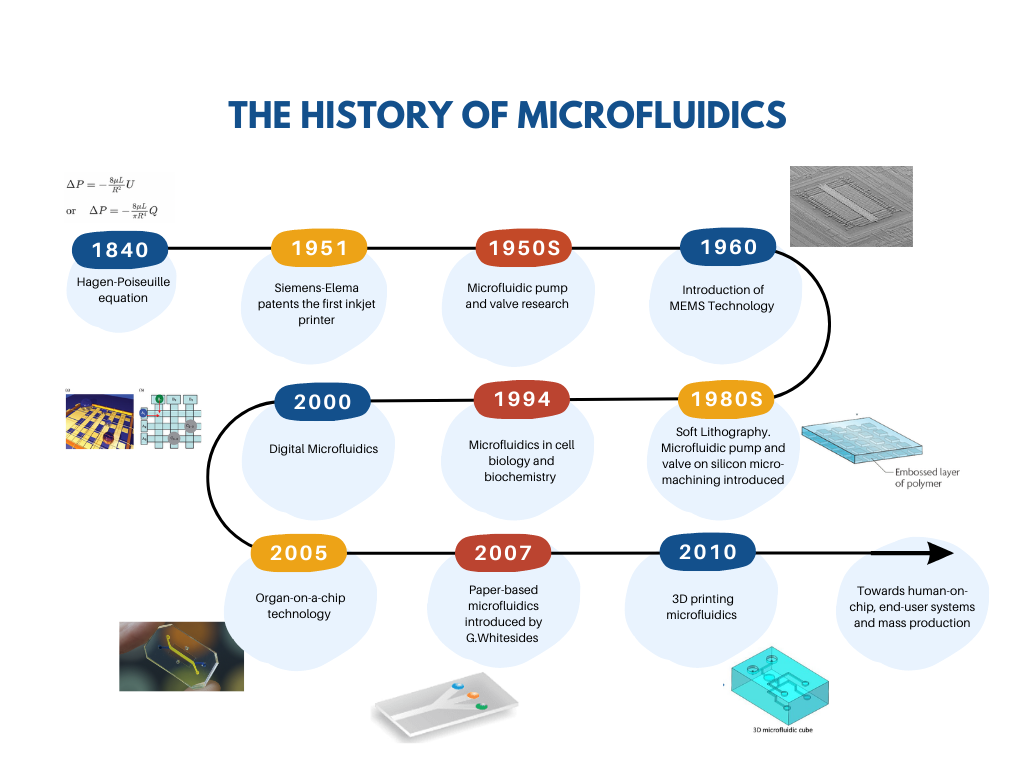

The history of Microfluidics

The development of advanced microfluidics is closely tied to a number of other fields, with significant contributions from microanalysis, biodefense, molecular biology and microelectronics.

Microfluidics enables the manipulation of extremely small volumes of samples and reagents, integrating multiple functions into compact, cost-effective devices. Initially, microfluidics was used in microbiology for analytical analysis. Furthermore, military research spurred significant advancements in microfluidics for defense applications, particularly in response to potential bacteriological threats.

The concept of microfluidics dates back to the 1950s with the development of inkjet printers, which utilised small tubes to transport ink for printing. In the 1970s, a miniature gas chromatograph was created on a silicon wafer. By the late 1980s, the introduction of silicon-based microvalves and micropumps paved the way for several silicon-based analytical systems.

In the 2000s, microfluidic diagnostic devices were successfully commercialised, leading to a surge in the development of diagnostic products and microfluidics companies. Since then, advancements in technologies such as 3D printing, 3D tissues, and organ-on-a-chip models have further propelled the growth of the microfluidics field.

Applications

One of the most significant developments in the medical device industry this decade has been the development of microfluidics, which has given rise to a number of applications that promise to further our understanding of the human body. With the creation of novel parts and procedures for the injection, mixing, pumping, and storage of fluids in the microchannels, the number of microfluidic systems applications in chemistry and biochemistry has grown over time.

Microfluidics is highly valuable in the field of biological and chemical analysis and diagnostics, for example, cancer and pathogen detection, thanks to its capabilities in using extreme small quantities of samples and reagents, lower experimental time, smaller devices, being more portable and high-resolution-and-sensitivity separation and detection.

Micro Fluidic Machining – Fully hardened 50 Rc Injection Mould Insert and Microfluidic COC Injection Moulding – Blood Analysis.

Microfluidic devices are integral to various advanced techniques such as capillary electrophoresis, isoelectric focusing, immunoassays, flow cytometry, mass spectrometry sample injection, PCR amplification, DNA analysis, cell separation and manipulation, and cell patterning. These devices also enable the measurement of molecular diffusion coefficients, fluid viscosity, pH levels, and chemical binding constants. In research, microfluidic systems are widely used in studying antibiotic-resistant bacteria, nanoparticle transport in blood, and chemical reaction kinetics.

In medical applications, microfluidics plays a crucial role in drug delivery systems, offering benefits such as reduced pain, minimized risk of side effects, and enhanced user-friendliness, safety, portability, and cost-efficiency. Microneedles, commonly used for transdermal drug delivery, can penetrate the skin without affecting nerve fibers. These microneedles come in various forms, including hollow (single or array of needles), solid (for creating skin pores), and porous (pre-filled with a drug). In terms of materials, microneedles can be dissolvable (water-soluble polymers), degradable (taking longer to degrade post-insertion), or swellable (absorbing interstitial fluid to facilitate drug transport without polymer dissolution).

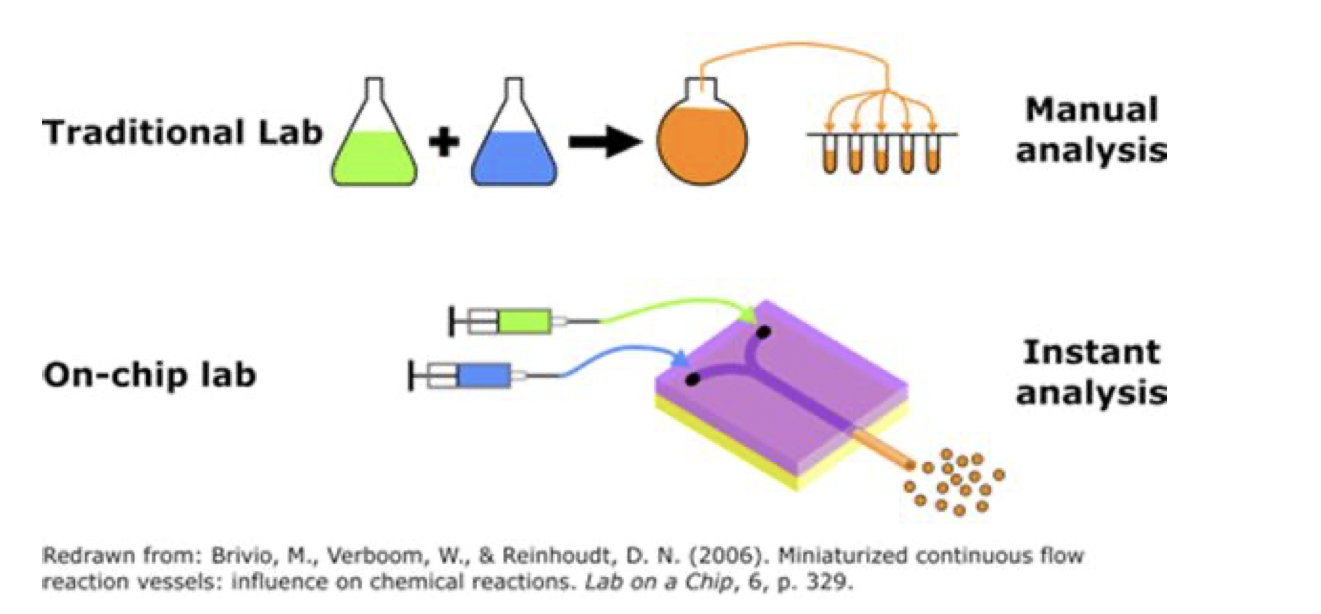

Lab-on-a-chip is gaining more popularity in recent years thanks to its advantages in low fluid volumes consumption, shorter response time, small footprints and portability. It is a miniaturised device that integrates into a single chip one or more analyses that are typically done in a lab, for analyses such as PCR and DNA sequencing, HIV status or biochemical detection. Organ-on-a-chip is a physiological organ biomimetic platform that reproduces the physiological environment of human organs, significantly helping scientists in researching human physiology for organs when testing for advancements in treatment or safety of new drugs.

Despite recent advancements in microfluidic technology, processing a variety of volumes and introducing samples still present various difficulties. Microfluidic methods have been improved thanks to recent advances in nanotechnology, revolutionsing very sensitive bioanalytical systems that can analyze challenging material.

The market for Microfluidics

According to the most recent study by Emergen Research, the size of the worldwide microfluidics market reached USD 20.14 billion in 2021 and is anticipated to experience a revenue CAGR of 16.1% during the projected period. By 2030, the microfluidics market size will reach USD 77.28 billion, with the driving factor being the higher demand from the healthcare industry. The microfluidics market is anticipated to have considerable global expansion during the forecast period as a result of the continued development of novel microfluidics technologies such 3-D printed microfluidics, paper-based microfluidics, and droplet-based microfluidics. Additionally, the incorporation of artificial intelligence (Al) and machine learning (ML) in microfluidic devices is expanding as a result of the potential of these technologies for real-time analysis and decision-making in a variety of applications.

In 2021, microfluidic chips captured a significant market share, driven by their adoption in biomedical and healthcare applications. The integration of advanced technologies like 3D printing and nanofabrication is expected to drive further market expansion.

Regarding materials, polymers led the market in 2021 due to their affordability and availability, making them the preferred choice for microfluidic devices.

Geographically, North America held the largest market share in 2016 and is expected to maintain its leadership throughout the forecast period, fueled by growing demand from the pharmaceutical and healthcare sectors. The Asia-Pacific region is anticipated to grow the fastest, driven by increasing demand and the presence of key industry players.

The future of Microfluidics

In recent years, microfluidics has become essential for applications like gene sequencing and point-of-care diagnostics. The COVID-19 pandemic showcased its advantages, enabling rapid viral mutation identification, point-of-care testing, vaccine research through flow cytometry, and organs-on-a-chip for understanding viral entry and cell responses. In the future, microfluidics will enable more detailed analysis of DNA, proteins, bacteria, and single-cell research. Advances in high-throughput screening and organ-on-a-chip technology will speed up drug development, reduce risks, and lower costs. Lab-on-a-Chip and other microfluidic devices will make diagnostics more affordable and faster to market, benefiting regions with limited healthcare resources.

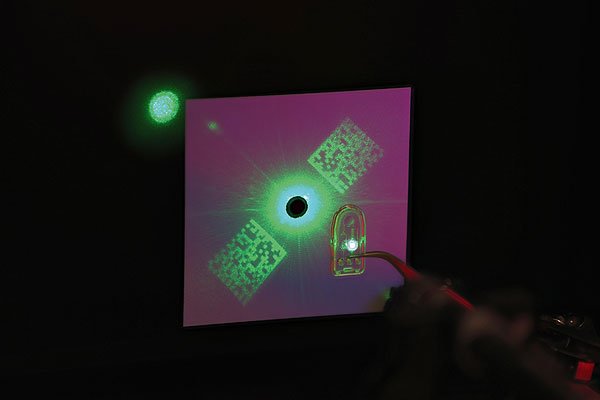

Micro Systems has the ability to add extra security verification by integrating a nano structure for the hologram of a QR code (a nanostructure of only 300 nm)

References:

Nguyen, N.-T., Wereley, S.T. and Mousavi, S.S.A. (2019) Fundamentals and applications of Microfluidics. Boston: Artech House.

Mu, X. and Zhang, Y.S. (1970) [PDF] Fabrication and applications of paper-based microfluidics: Semantic scholar. [PDF] Fabrication and Applications of Paper-Based Microfluidics | Semantic Scholar. Available at: https://www.semanticscholar.org/paper/Fabrication-and-Applications-of-Paper-Based-Mu-Zhang/276d3110228d7a8b18bba8c578d7557472c4674d (Accessed: 11 May 2023).

Digital Microfluidics (no date) Digital Microfluidics – an overview | ScienceDirect Topics. Available at: https://www.sciencedirect.com/topics/chemistry/digital-microfluidics (Accessed: 11 May 2023).

(No date) Developments of 3D printing microfluidics and … – Wiley Online Library. Available at: https://analyticalsciencejournals.onlinelibrary.wiley.com/doi/abs/10.1002/elan.201600043 (Accessed: 11 May 2023).

B. Weibel, W.R. DiLuzo and G.M. Whitesides, Microfabrication meets microbiology, Nature Rev. Microbiol. (2007), Vol. 5, No.3, pp. 208-218.

(No date) Developments of 3D printing microfluidics and … – Wiley Online Library. Available at: https://analyticalsciencejournals.onlinelibrary.wiley.com/doi/abs/10.1002/elan.201600043 (Accessed: 11 May 2023).

(No date) Developments of 3D printing microfluidics and … – Wiley Online Library. Available at: https://analyticalsciencejournals.onlinelibrary.wiley.com/doi/abs/10.1002/elan.201600043 (Accessed: 11 May 2023).

Brivio, M., Verboom, W., & Reinhoudt, D.N. (2006). Miniaturized continuous flow reaction vessels: influence on chemical reactions. Lab on a Chip, 6, p.329.

Micro Systems’s vast know-how in design, ultra-precision micro machining capabilities and expert knowledge in micro moulding technology allow us to manufacture advanced microfluidic moulds with tolerance as low as +/-0.001mm, with integrated optics. We have a dedicated micro moulding facility, and have ISO13485 and ISO9001 certifications. For more information, please Contact us or visit our website.