Micro Systems Singapore celebrates 15 years of mould tooling Innovation and Excellence

Micro Systems Singapore, one of the market leaders in ultra-precision moulds and tooling, is pleased to celebrate the company’s 15 anniversary in Singapore, marking a major milestone of Micro Systems’ operations abroad.

After 15 years of successful operation, Micro Systems is well established in Singapore, initially occupying space at Science Park 2, before relocating to the prestigious MedTech Hub, a purpose built Medical Device GMP designed facility. Micro Systems Singapore enables Micro Systems to fully support and service customers operating in South East Asia and the far-East, with shorter time-scales and more efficient customer support with a multilingual team at close call.

Micro Systems Singapore has extensive expertise and technologies to meet your precision engineering demands in medical device, diagnostic, microfluidics, ophthalmic and other specialist projects. The machinery on hand in Singapore is a duplicate of our UK facility, which ensures Micro Systems Singapore performs to the highest standards set by Micro Systems (UK). The duplicate machinery and software, coupled with the closely-knit team across Singapore and UK, allows for seamless communication and data transfer between designers, manufacturing engineers and quality assurance across the 2 sites. Both UK and Singapore sites ensure that Micro Systems have contingency arrangements in place should there be disruption in either of the sites.

Photo: Micro Systems Singapore’s facilities at MedTech Hub

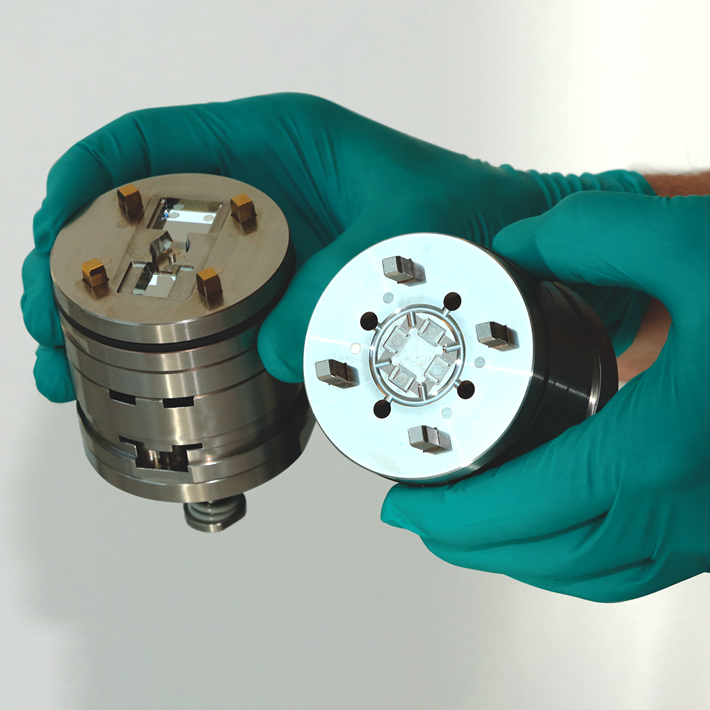

The operations in Singapore are geared towards efficient and cost effective first stage manufacturing of medical device moulds with reduced lead times. Micro Systems Singapore is equipped with an Injection Mould Manufacturing EDM Section, Specialist Micro and Wire EDM machines, Kern Micro milling and Mikron HSM, together with inspection capabilities accurate to sub-micron, in-line with Micro Systems high standards across the board. Micro Systems Singapore also provides mould testing and validation for small parts and micro moulded components with Micro Systems’ 50 micro moulding machines, conventional all-electric Fanuc 15T – 100T injection moulding machines to allow for mould testing and development without needing to ship the tools back to Micro Systems UK. Micro Systems Singapore is ISO 9001 accredited, with ISO 13485 accreditation planned for 2024, and houses cleanroom production facilities for medical devices.

Talking about the 15th year celebration, Henry Tay, General Manager at Micro Systems Singapore, said: “It is another great milestone for us, especially to our pioneer staff. We owe our achievement to our unwavering trust and support from the Company board, management and staff, when they are thousands miles away in the UK. We are preparing ourselves to meet up with new technologies for the next lap, fulfilling higher engineering requirements and standards for Micro Systems”.

Looking forward, Micro Systems Singapore aims to reach more customers in this fast-growing part of the world, where the demand for advanced technology in medical, healthcare and diagnostics is developing at an amazing speed. At the same time, Micro Systems Singapore hopes to become the bridge between the UK and Singapore, connecting talents and new opportunities within medical/pharmaceutical, ophthalmics, diagnostics and drug delivery industries, welcoming new innovations and product developments to further improve the lives of millions around the world.

Photo: Our amazing team at Micro Systems Singapore

About Micro Systems

Micro Systems is a leading manufacturer in precision-engineered injection moulds and micro moulds for the medical, pharmaceutical and ophthalmic markets. Micro Systems offers innovative solutions for designing and manufacturing multi-cavity, high-volume moulds, and turnkey solutions for medical device manufacturing needs, with Class-7 cleanroom production capabilities. In addition to mould making and component supply, Micro Systems also provides factory acceptance testing (FAT), mould validations and technical moulding support as part of our comprehensive service. The company is ISO 9001 and ISO 13485 certified, and has facilities in Warrington, UK and in Singapore.

Micro Systems (UK) Ltd

101 Golborne Enterprise Park, Warrington, WA3 3GR