Meet our amazing precision engineering team in Singapore

Micro Systems started our journey in Singapore in 2009. Fast forward 14 years, and now we proudly expand to a team of 12 strong individuals with considerable expertise in precision engineering, micro mould design and engineering project management.

We first opened our Singapore facility in Science Park 2, which was then relocated to the MedTech Hub, a purpose built Medical Device GMP designed facility. Our Singapore facility is a great opportunity for us to showcase to our customers on this site of the world our state-of-the-art mould manufacturing operation and machinery, which duplicate our office in the UK and ensure seamless communication of designs, manufacturing and QA data between the 2 sites. Additionally, as the demand for micro moulding is increasing at a phenomenal rate, especially in Asia, having a well-established facility in Singapore helps us serve our customers there more efficiently with shorter lead times.

Since our establishment in Singapore, we have also built a strong partnership with Nanyang Technology University, running apprenticeship programmes and technology exchange.

Let’s meet some of our amazing humans at Micro Systems Singapore, who make us a greater company each day!

How long have you been working at Micro Systems? What’s your best memory of working at Micro Systems?

Teoh Chia Heap : I have worked here for 13 years. Hah, I once received a call at 2 a.m Singapore time from Mr. Gerry (based in the UK) as he was mistaken about the time difference 🙂

Lam Chee Keong : I have been here for 10 Years. Hmm, it was definitely attending a fun dinner & dance even in the UK!

Moses : It has been 7 years and 4 months. The first time I met Gerry, he kept saying my name as “Moses”. Like Moses Mill…..

Yvonne : I joined Micro Systems 12 years ago. I really enjoyed my time learning & working with Micro Systems in the UK for 5 months.

What is a “fun” or “interesting” or “challenging” project you’ve been on?

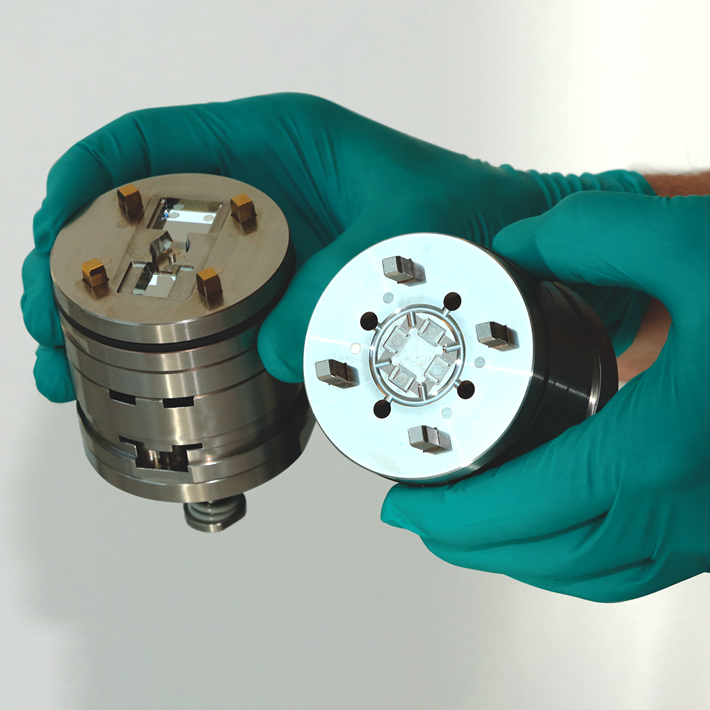

Teoh Chia Heap : Definitely it’s the 20160 Plunger tools as it is the first double colour project for me in Micro Systems.

Lam Chee Keong : It is my project on S10420 Nozzle Bodies manufacture of 0.20 ±0.005 holes.

Moses : Can’t forget the non-stop working for 34 hours for the project S11840_Grippers. We needed 5 settings per piece for this project.

Yvonne : A few times working overnight in the office to do Quality Control jobs.

What’s been your favourite team activity at Micro Systems?

Teoh Chia Heap : I can’t forget our 10-year anniversary celebration at Sentosa in Singapore.

Lam Chee Keong : Our company trip to Phuket Island in Thailand in 2019, just before the Covid-19 lockdown! It was so much fun for the whole team. We all hope that we can go to other places too like Macau, Taiwan for our coming trips.

Moses : We have a lot of after-work activities, like going bowling or eating out with our managers and other colleagues.

Yvonne : Just like Lam Chee Keong, it is definitely our company trip to Phuket Island in 2019. I look forward to more trips for our team bonding.

What would you want someone to know coming into your role?

Teoh Chia Heap : I think to be successful in this competitive industry, having experiences in the moulding will be best.

Lam Chee Keong : Knowledge in machining is highly valued when you come to this industry.

Moses : The first must have is machining knowledge.

Yvonne : I would strongly recommend having experience in mould manufacturing process planning, and Quality Control (QC) & Quality Management System (QMS), as well as other administration works.

What’s been the most challenging part of your role?

Teoh Chia Heap : I will say how to come up with simple and compact designs, but they have to be doable and fun to work with.

Lam Chee Keong : Manufacturing of tight tolerance parts, which is probably one of the most challenging things for all experts in this industry.

Moses : I will say it’s the aim to lessen the time to set up a task, and to maintain the highest quality for all pieces before delivering to our customers.

What’s something you’ve worked on that you’re proud of?

Teoh Chia Heap : I definitely love all the design and the assembly of the tools that I design.

Lam Chee Keong : Machining of -0.002 mm profiles!

Moses : It always gives me great satisfaction when I could complete a project in less time and at a lower cost.

Yvonne : I was so proud of myself when I managed to learn and help our team when Micro Systems Singapore started the implementation process of the QMS (ISO 9001).

Who do you admire in the micro mould/moulding industry and why?

Teoh Chia Heap : To me, it’s Mr. Moses Lee (CAM) because he can machine the 2 micron tolerance of flatness for FR 1.5 project with Micron S500. What a great piece of work it is!

Lam Chee Keong : Mr. Gary (our managing director) because he set up Micro Systems in both the UK and Singapore, and develops future technologies in the medical field.

Moses : Mr. Tang Gek Hai (our ex-manager). He is the person who is able to handle the mould by himself, from raw material to a finishing mould set.

Yvonne : It’s Mr Henry Tay, our manager at Micro Systems in Singapore. He is very passionate about the mould industry and always eager to guide our team.

How is the team at Micro Systems helping you in your daily work? Do they support your future career growth?

Teoh Chia Heap : In both the UK and Singapore, everyone is super helpful and we are all working really well as a team with great teamwork spirit. I definitely feel that everyone here supports my future career growth.

Lam Chee Keong : I love the fact that all people of Micro Systems are understanding of each other, and they always help each other whenever possible.

Moses : Everyone is extremely friendly and helpful to solve my problems. And yes, definitely I receive great support from the company to excel in my future professional growth.

Yvonne : I love the fact that everyone is so kind and helpful.

How does the cooperation work between the teams in Singapore and the UK? What do you enjoy the most from working within a multinational team?

Teoh Chia Heap : For the last 13 years that I have been working here, I think the way both teams work together is good. All information needed is passed around effectively without any problem. The designers from both sides always help each other in updating or modifying our drawings for best results.

Lam Chee Keong : The teams in Singapore and the UK are always on the same page when it comes to the design requirements from our customers, and from the other team. I do enjoy getting to know more about each other’s culture and social customs.

Moses : I think that despite the differences in time zones and geography, we all provide the required information very clearly and effectively. We could share different ideas with each other and solve problems quite quickly.

Yvonne : Both the UK and Singapore offices manage to communicate well through email and conference calls despite being in different time zones (It’s a 7 hour difference!). I definitely enjoy sharing different cultures, stories and ideas when working with this multinational team!

Our team in Singapore would love to help you with your micro mould project!

Microsystems Engineering Solutions Pte Ltd

JTC Medtech Hub 05-02

Singapore 618305

Tel: +65 9794 4700

Singapore fun fact!

- Singapore is one of the smallest nations in the world.

- There are 64 islands in this metropolis, not just one!

- Singapore is one of the greenest cities in the world, with green space covering about half of its total area (~700 km2).

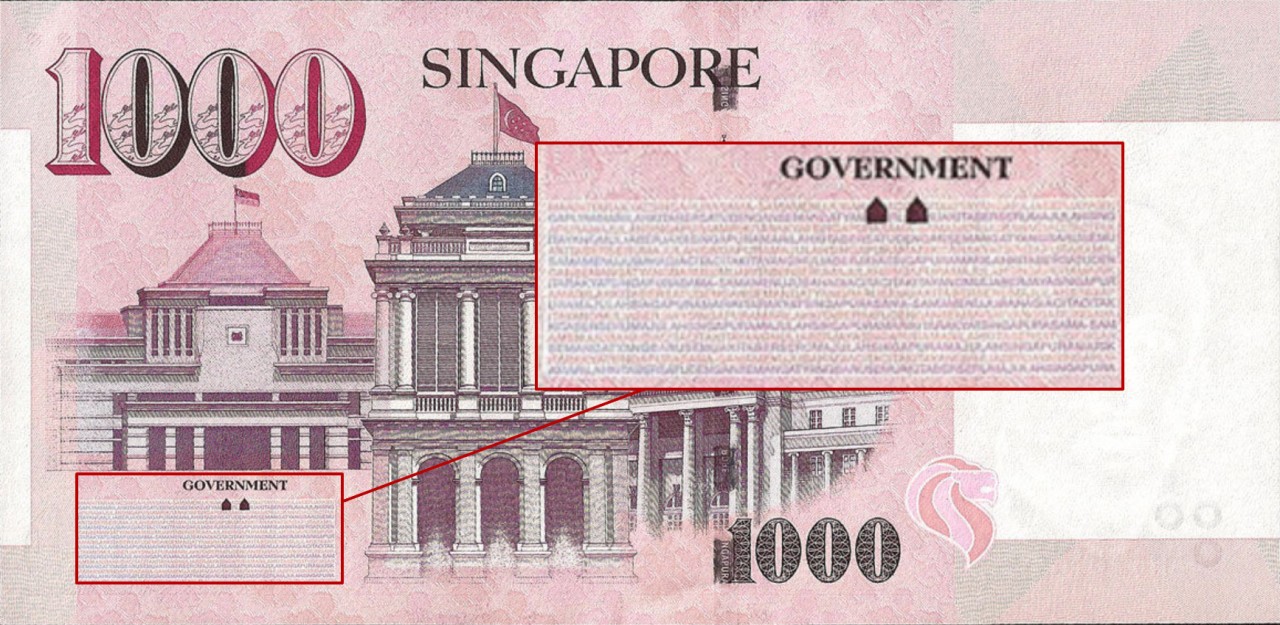

- The National Anthem of Singapore can be found on the back of the SGD 1000 note, written in micro text.

- Singapore’s four official languages are Malay, Mandarin, Tamil and English. Because of its bilingual education policy, most citizens speak two or more languages.

- 19.4 degrees Celsius was the lowest temperature ever measured in Singapore on January 31, 1934.

- Everything from sand to freshwater is imported, and Singapore’s whole economy is centred on shipping.

- According to a business ranking released by the World Bank, Singapore is the second-easiest location to conduct business globally, after New Zealand.

- Singapore is the fifth-least corrupt city in the world and the least corrupt city in Asia.

- Singaporeans walk at an average pace of 6.15 kilometres per hour, making them the world’s quickest walkers!

Micro Systems specialises in the design, manufacture and validation of ultra precision micro moulds for the medical, pharmaceutical and optical markets, at the same time, the development and use of micro and nano technologies in the design and manufacture of injection moulded components. We have a dedicated micro moulding facility, and have ISO13485 and ISO9001 certifications. Micro Systems strives to create a positive working environment where respect, teamwork, training, communication and opportunity are at best. For more information, please Contact us or visit our website.