ISO 13485 Traceability and Automated In-Line Inspection for Medical Injection Moulding: Ensuring Compliance and Quality

Introduction to ISO 13485 Traceability in Medical Injection Moulding

In the highly regulated medical device industry, achieving ISO 13485 traceability in medical injection moulding is essential to meet strict quality and regulatory standards. This international standard governs quality management systems specifically for medical devices, requiring manufacturers to maintain detailed traceability of materials, processes, and finished products to guarantee patient safety and product efficacy (Wikipedia 2025; Micro Systems 2025).

Key Requirements for Traceability Under ISO 13485 in Medical Injection Moulding

Effective traceability in medical injection moulding involves documenting every critical element of production, including batch-level raw material tracking, tooling information, machine settings, and quality inspection data (bprhub.com 2025). This traceability is critical for Class II and Class III medical devices where strict audit trails are mandatory.

Manufacturers must implement comprehensive documentation systems such as Device History Records (DHRs) and Device Master Records (DMRs), alongside process validation protocols like Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) to ensure reproducibility and regulatory compliance (Micro Systems 2025).

Benefits of Automated In-Line Inspection for Medical Injection Moulding Quality Control

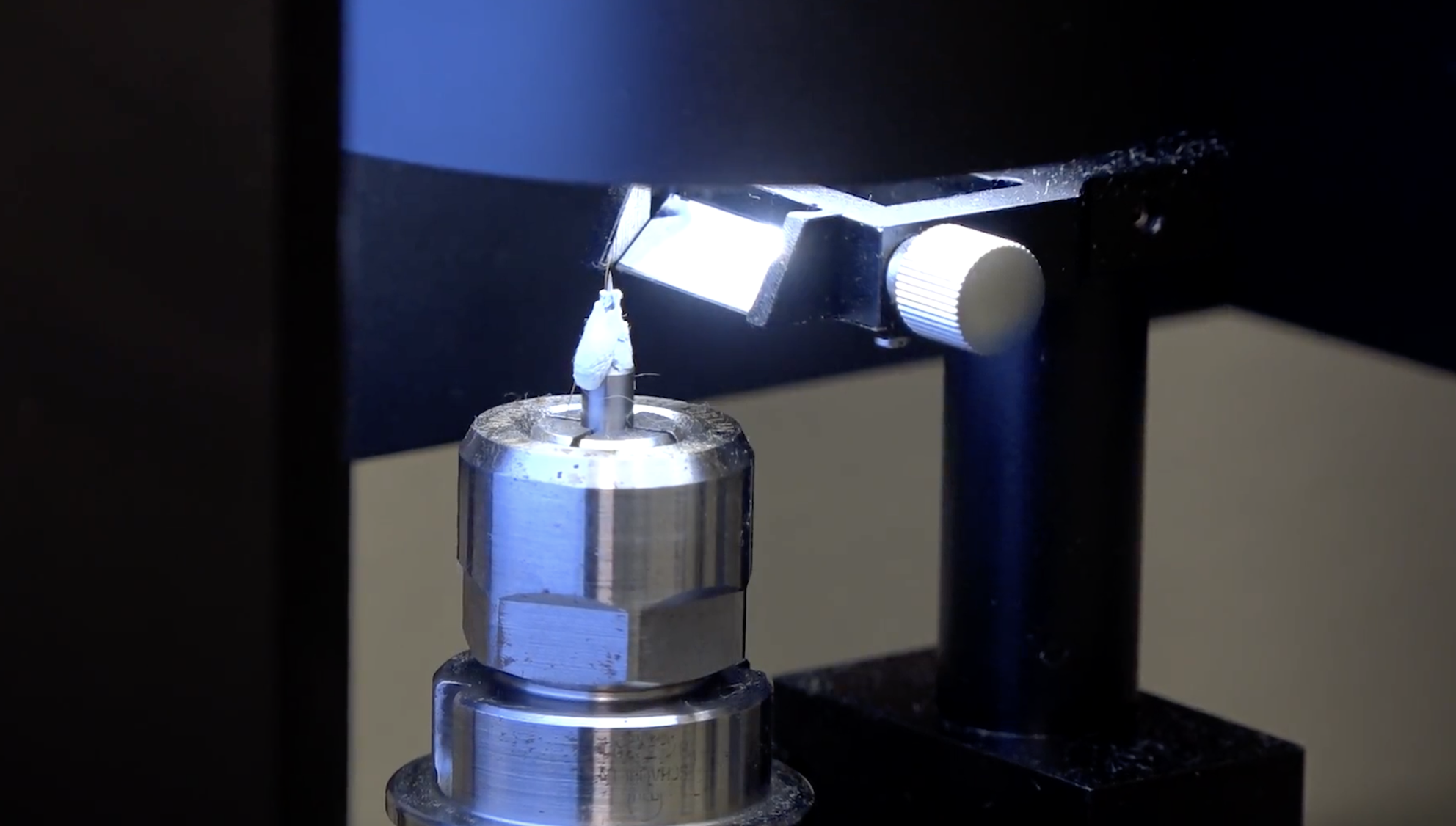

Integrating automated in-line inspection for medical devices within injection moulding lines significantly enhances defect detection and quality assurance. Using advanced machine vision systems and sensor technology, manufacturers can detect microscopic defects and dimensional variances in real time, minimising scrap rates and human error.

Coupled with Statistical Process Control (SPC) and First Article Inspection (FAI), automated inspection facilitates continuous process monitoring and rapid corrective actions to maintain the highest standards required in medical device production

Digital Thread Traceability: Revolutionising Medical Injection Moulding

The adoption of digital thread traceability in injection moulding connects every stage of the manufacturing process into an integrated, time-stamped digital record. From initial design and raw material sourcing to machine parameters and inspection results, the digital thread enables full visibility and audit readiness.

This continuous digital record supports regulatory compliance and intellectual property protection, while cloud-based Manufacturing Execution Systems (MES) allow real-time process control and rapid recall capabilities essential in medical device manufacturing (Med-Tech Insights 2025).

Regulatory Compliance and Operational Excellence through Traceability and Inspection

Complete traceability combined with automated inspection ensures adherence to global medical device regulations, including FDA QSR, EU MDR, and UK MDR (todaysmedicaldevelopments.com 2025).

Early defect detection through these systems improves First Pass Yield (FPY), reduces costly rework, and supports effective Corrective and Preventive Actions (CAPA), thereby enhancing product quality and reliability. This optimisation of processes strengthens trust with Original Equipment Manufacturers (OEMs) and increases competitive advantage.

For medical device manufacturers, integrating ISO 13485 traceability in medical injection moulding with cutting-edge automated in-line inspection and digital thread traceability is indispensable. These technologies guarantee compliance, ensure patient safety, and improve manufacturing efficiency. By embracing these systems, manufacturers can meet rigorous regulatory demands and maintain leadership in the competitive medical device market.

Micro Systems specialises in delivering advanced solutions tailored to the unique demands of medical injection moulding. Our expertise encompasses implementing fully integrated traceability systems that capture and manage comprehensive production data, from raw material batch tracking to final inspection records, ensuring compliance with ISO 13485 requirements. By partnering with Micro Systems, medical device manufacturers benefit from enhanced process visibility, faster defect identification, and seamless audit readiness, all critical to meeting regulatory demands and optimising operational efficiency.

Contact us today!