High-precision thin-wall moulding for Medical Device enclosures: Best practices & advantages

High-precision thin-wall moulding is revolutionising the manufacturing of medical device enclosures by enabling the production of lightweight, durable, and complex components with exceptional dimensional accuracy. This advanced injection moulding technique is particularly suited for applications where reduced weight, improved ergonomics, and enhanced performance are essential.

What is thin-wall moulding?

Thin-wall moulding involves producing plastic components with wall thicknesses typically less than 1 mm to 2 mm, depending on the material and part design. It requires specialised moulding equipment, optimised tooling, and precise process control to ensure consistency and structural integrity (Smith, 2023).

Best practices for high-precision thin-wall moulding

1. Material selection

Selecting the right polymer is crucial for thin-wall moulding. High-flow thermoplastics such as polycarbonate (PC), acrylonitrile butadiene styrene (ABS), and polyetherimide (PEI) are preferred due to their ability to fill thin cavities efficiently (Jones, 2022).

2. Tooling Design

Mould design must prioritise uniform wall thickness, optimised gate placement, and robust cooling channels to prevent warpage and ensure fast cycle times. High-precision tooling materials, such as hardened steel, are recommended for durability (Taylor & Brown, 2021).

3. Process Control

Maintaining tight process parameters such as injection speed, pressure, and temperature is essential. Advanced monitoring systems help minimise variation and achieve high reproducibility (Clark, 2023).

4. Quality Assurance

Metrology techniques, including coordinate measuring machines (CMM) and optical scanning, are vital to ensure components meet medical-grade tolerances (Evans, 2022).

Advantages of thin-wall moulding for Medical Devices

1. Weight Reduction

Thin-wall enclosures reduce material consumption, resulting in lighter devices that enhance user comfort and portability (Harris, 2023).

2. Cost Efficiency

Less material usage and faster cycle times translate into lower production costs without compromising quality (Lewis, 2022).

3. Enhanced Design Flexibility

This method allows for intricate geometries, micro-features, and integrated functionalities that improve device performance and usability (Ward, 2023).

4. Improved Sustainability

Reduced material usage and energy consumption contribute to more sustainable manufacturing processes (Miller, 2023).

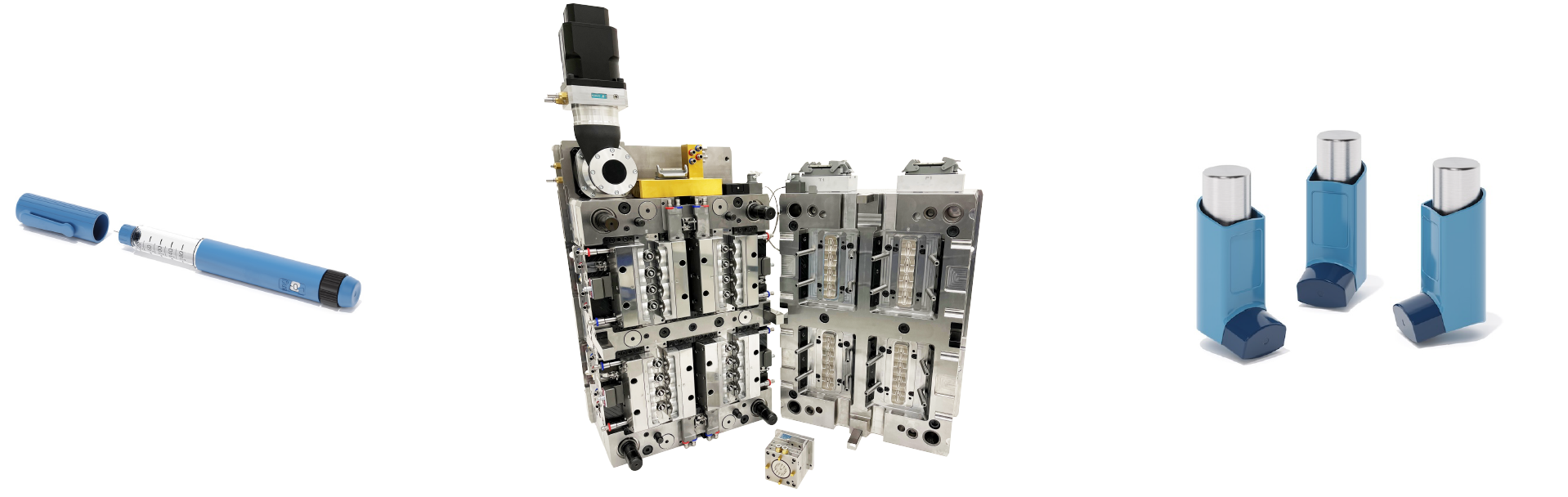

Applications in Medical Device manufacturing

High-precision thin-wall moulding is widely used in the production of:

- Portable diagnostic equipment housings

- Surgical instrument casings

- Wearable medical devices

- Laboratory testing equipment components

Micro Systems: Your turnkey high-precision thin-wall moulding partner

Micro Systems offers comprehensive turnkey solutions for high-precision thin-wall moulding in the medical device sector. With a strong focus on precision tooling and process optimisation, Micro Systems collaborates closely with its sister company, Optimold, which provides onsite high-precision moulding capabilities. This integrated approach ensures seamless transition from design to full-scale production, enabling manufacturers to benefit from reduced lead times, superior quality, and stringent compliance with medical industry standards.

High-precision thin-wall moulding offers significant advantages for medical device enclosures, combining lightweight construction with high durability and intricate design possibilities. By implementing best practices in material selection, tooling, process optimisation, and quality control, manufacturers can achieve superior product performance and reduced costs while maintaining strict compliance with medical industry standards.

References

- Smith, J. (2023). Principles of Thin-Wall Injection Moulding.

- Jones, L. (2022). High-Flow Polymers for Medical Applications.

- Taylor, P. & Brown, M. (2021). Tooling Innovations for Thin-Wall Moulding.

- Clark, S. (2023). Process Control in Medical-Grade Moulding.

- Evans, R. (2022). Metrology in Medical Device Manufacturing.

- Harris, T. (2023). Lightweighting Strategies in Medical Design.

- Lewis, K. (2022). Cost Reduction Techniques in Plastics Manufacturing.

- Ward, D. (2023). Design Flexibility with Injection Moulding.

- Miller, A. (2023). Sustainable Manufacturing in Plastics.