Designing Multi-Cavity Moulds for High-Volume Auto-Injector Component Production

Auto-injectors are critical drug delivery devices used for treatments such as biologics, epinephrine, and insulin. Their components, typically including housings, plungers, and activation mechanisms, are produced in very high volumes with tight regulatory and dimensional requirements. Multi-cavity moulds enable economical, high-throughput production, but they also present unique challenges in flow balance, thermal control, cavity-to-cavity variation, and regulatory compliance. A robust multi-cavity mould design ensures repeatability, reduced scrap, and accelerated time-to-market, particularly under ISO 13485 quality management requirements ([ISO 13485:2016]; [Goodship & Middleton, 2019]).

Why Multi-Cavity Moulds for Auto-Injectors?

High-volume auto-injector production demands millions of parts per year, often with annual quantities exceeding 20–50 million components for a single device programme. Multi-cavity moulds (commonly 8, 16, 32 or 64 cavities; high-output systems may reach 96 or even 128 cavities) deliver:

- Lower cost per part through cycle time efficiency and tooling amortisation.

- Consistent part quality via symmetrical cavity layouts and balanced melt flow.

- Improved scalability for global manufacturing platforms ([Plastics Design & Moulding, 2023]).

Typical cycle times for auto-injector components are:

- Thin-walled housings (PC, COC, ABS): 15–25 seconds

- Plungers and drive mechanisms (POM, PA, PP): 20–30 seconds

- Complex multi-material components (overmoulded TPE seals): 25–40 seconds depending on cooling requirements ([Menges & Mohren, 2018]).

The most frequently used medical-grade polymers include:

- Polycarbonate (PC): high dimensional stability and impact resistance.

- Cyclic Olefin Copolymer (COC/COP): excellent transparency and biocompatibility.

- Polyoxymethylene (POM): low friction for moving parts such as plungers.

- Polypropylene (PP): cost-effective for disposable housings.

- Polyamide (PA) and ABS: used in non-patient-contact structural parts ([Goodship & Middleton, 2019]).

Key Design Considerations

1) Cavity Balance and Hot Runner Design

A primary challenge in multi-cavity moulds is achieving consistent filling and pressure across all cavities. Unbalanced flow can cause dimensional variation, flash, or short shots. Strategies include:

- Using naturally balanced hot runner systems with equal-length flow channels.

- Employing melt flow simulations (Moldflow, Sigmasoft) to optimise gating and temperature zones ([Goodship & Middleton, 2019]).

- Incorporating valve gate technology for sequential filling in complex geometries.

2) Tool Steel Selection and Surface Finish

Auto-injector components require tight tolerances (±0.01–0.02 mm) and often involve medical-grade polymers (e.g., COC, PC, POM). Recommended tool steels:

- H13 or S136 (stainless) for corrosion resistance in cleanroom conditions.

- PVD or DLC coatings to reduce friction and wear on high-cavity tools ([Baldwin, 2021]).

Surface finishes should comply with VDI 3400 or SPI standards to ensure correct optical and tactile properties.

3) Cooling System Integration

Cycle time dominates cost in high-volume moulding. Conformal cooling channels (via additive manufacturing) improve thermal uniformity, reducing warpage and improving cavity-to-cavity repeatability ([Menges & Mohren, 2018]).

4) Ejection and Part Handling

Uniform ejection is critical for delicate auto-injector parts:

- Use multi-point ejector systems with minimal deformation risk.

- Integrate robotic pickers and in-mould sensors to detect non-ejected parts, preventing tool damage ([Plastics News Europe, 2022]).

5) Dimensional Tolerance Control

Auto-injectors are regulated as combination products, requiring consistent mechanical function. Tolerances must consider:

- Cavity-to-cavity variation due to thermal gradients.

- Mould wear over production lifetime (1–5 million cycles).

- Post-mould shrinkage of medical-grade polymers ([Goodship & Middleton, 2019]).

6) Cleanroom Compliance and ISO 13485

Multi-cavity moulds for medical devices must comply with ISO 13485:2016, which mandates:

- Controlled environments (ISO Class 7–8 cleanrooms).

- Lot traceability and documentation.

- Design validation and risk management (FMEA, pFMEA) ([ISO 13485:2016]).

Process Validation for High-Volume Production

Validation follows the IQ/OQ/PQ framework:

- Installation Qualification (IQ): Verifies tool and ancillary equipment installation.

- Operational Qualification (OQ): Confirms moulding parameters meet specification limits.

- Performance Qualification (PQ): Demonstrates consistent production at nominal process settings.

Statistical tools such as Cp/Cpk analysis are used to confirm that critical-to-quality (CTQ) features meet acceptance criteria (Cpk ≥ 1.33) ([Menges & Mohren, 2018]).

Emerging Trends in Multi-Cavity Tooling

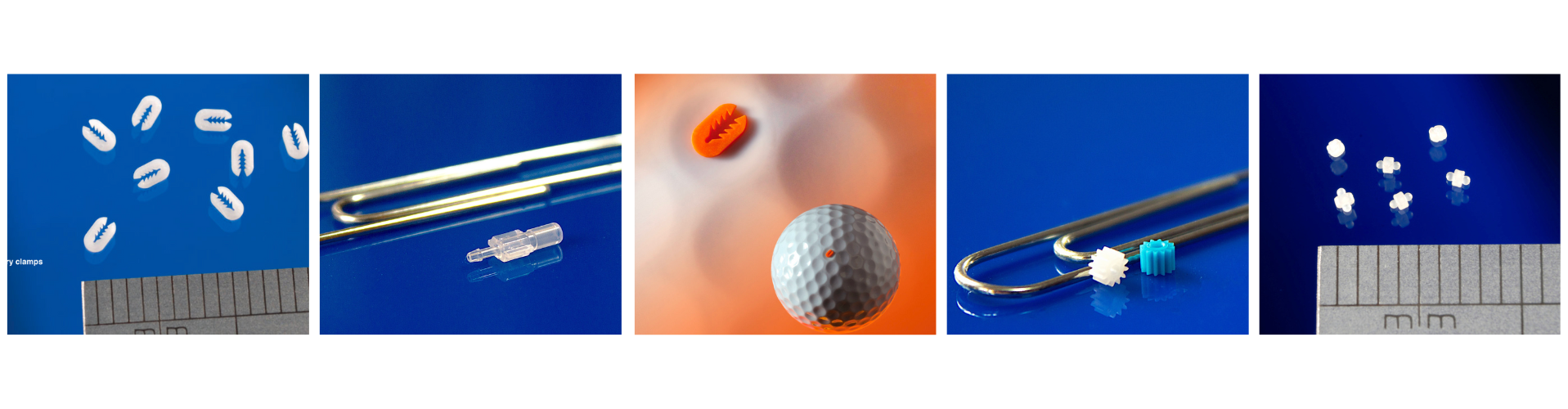

- Micro-moulding for integrated drug-delivery components, including microneedles.

- AI-assisted process control for real-time cavity monitoring.

- Modular tool designs allowing cavity expansion as production ramps ([Plastics Design & Moulding, 2023]).

How Micro Systems Can Help

Micro Systems specialises in precision multi-cavity tooling for medical and drug-delivery devices, including auto-injectors. Their capabilities include:

- High-precision machining and micro-milling achieving tolerances down to ±2 µm on functional features.

- Conformal cooling channel design for optimised cycle times.

- Integrated metrology and ISO 13485-certified quality systems ensuring full regulatory compliance.

- Rapid tool validation and process optimisation using advanced simulation and SPC techniques, reducing time-to-market for high-volume programmes.

By leveraging decades of expertise in medical moulding, Micro Systems assists OEMs in achieving repeatable, compliant and cost-effective mass production of auto-injector components.

Designing a multi-cavity mould for auto-injector components is a complex, multidisciplinary task involving melt flow, thermal management, regulatory compliance, and statistical process control. Early collaboration with experienced tooling specialists ensures:

- Consistent cavity balance

- Optimised cooling and cycle time

- Regulatory-ready validation packages

As the demand for self-administration devices grows, multi-cavity moulding will remain the cornerstone of high-volume, high-quality auto-injector production ([ISO 13485:2016]; [Baldwin, 2021]).

References

- ISO 13485:2016 – Medical devices – Quality management systems – Requirements for regulatory purposes.

- Goodship, V., & Middleton, D. (2019). Injection Moulding: Methods and Design. Smithers Rapra.

- Baldwin, R. (2021). Tool Steel Selection for Medical Device Injection Moulding. Plastics Technology Europe.

- Menges, G., & Mohren, P. (2018). How to Make Injection Moulds. Hanser Publications.

- Plastics News Europe (2022). Automation and Ejection Systems in High-Cavity Medical Moulds.

- Plastics Design & Moulding (2023). Trends in High-Volume Medical Device Moulding.