Comparing Micro vs. Traditional Injection Moulding for Medical Devices

Injection moulding has long been a cornerstone manufacturing process for medical devices due to its precision, repeatability, and scalability. However, the growing demand for miniaturised and high-performance medical components has accelerated the development and adoption of micro injection moulding (μIM) technologies.

Introduction to Injection Moulding in Medical Devices

Medical devices often require components that are complex, made to tight tolerances, biocompatible, and produced in sterile environments. Injection moulding meets these criteria and is widely employed for components such as catheters, surgical instruments, drug delivery systems, and diagnostic equipment.

With miniaturisation becoming increasingly important—especially for minimally invasive and implantable devices—micro injection moulding is gaining traction. Understanding the distinctions between micro and traditional moulding is vital for manufacturers aiming to meet both design and regulatory requirements.

Definitions and Scope

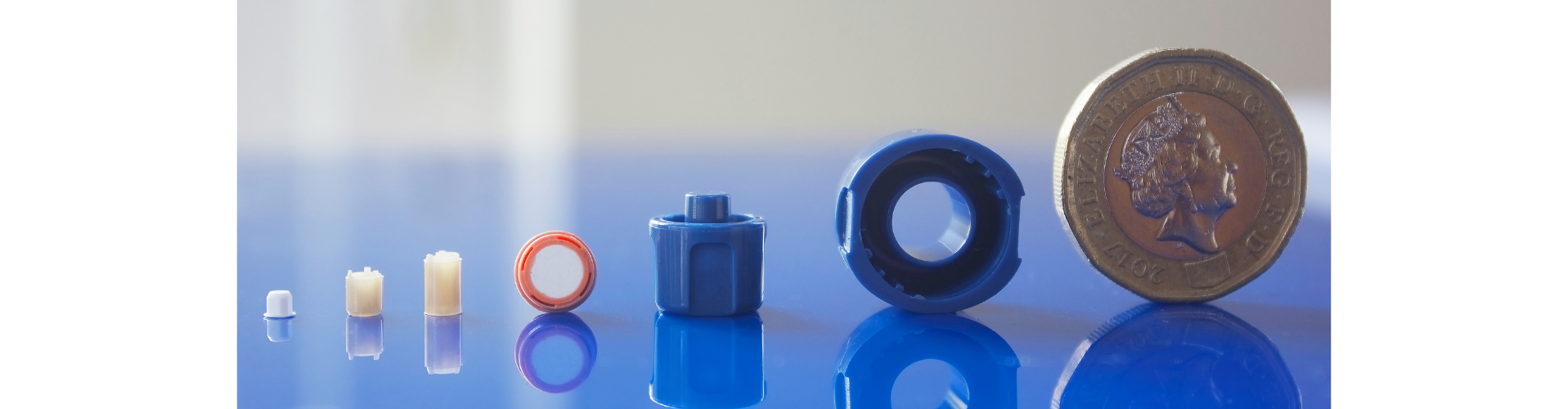

Traditional Injection Moulding typically refers to the manufacture of plastic parts with weights above 1 gram and tolerances in the range of ±0.05 mm or more.

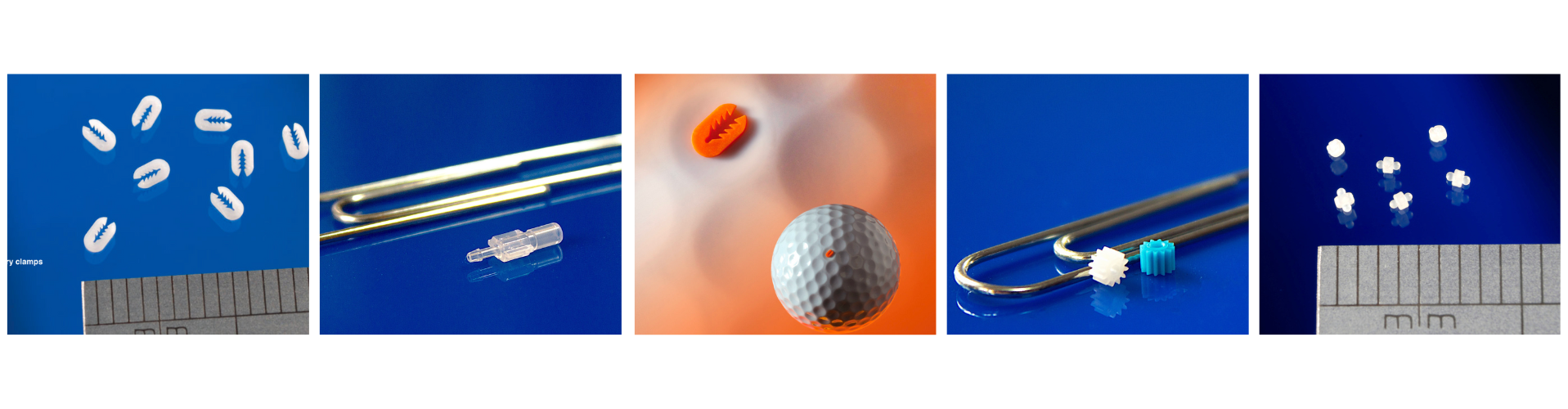

Micro Injection Moulding, on the other hand, is generally defined by:

- Part weights < 1 gram (often < 0.1 g)

- Feature sizes in the micrometre range

- Tolerances down to ±0.005 mm

- Shot weights as low as a few milligrams

These criteria make μIM suitable for components such as microfluidic devices, microneedles, and micro-optics used in advanced diagnostics and therapeutics.

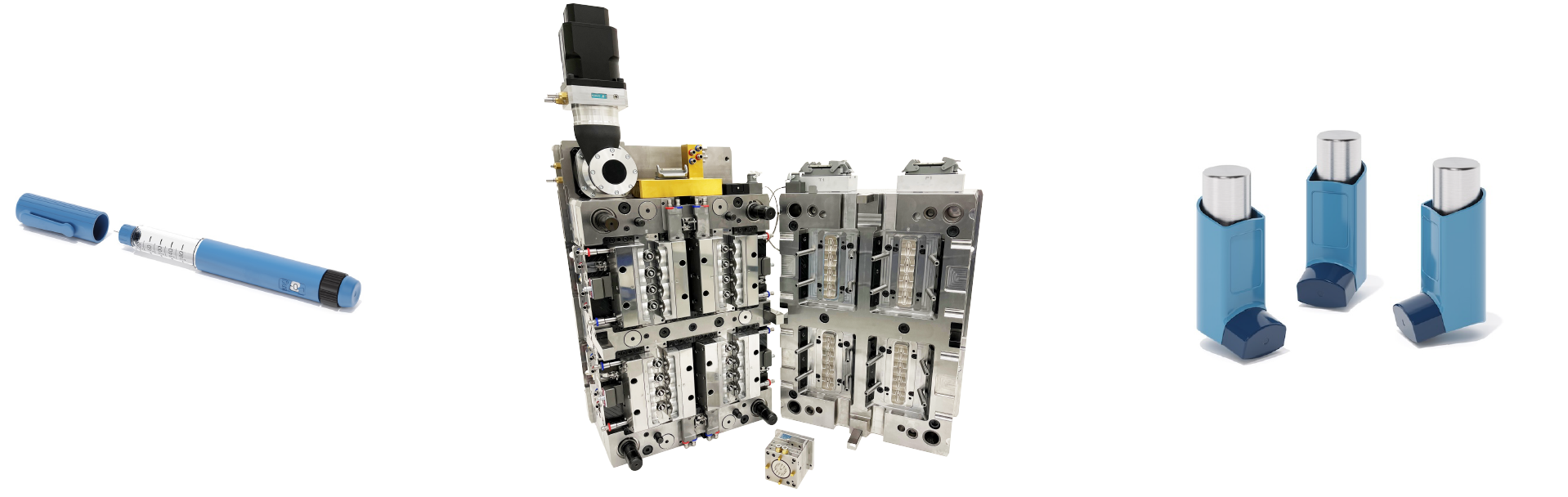

Tooling and Mould Design Differences

Mould Base and Cavities

Micro moulds often use high-precision steel alloys and require ultra-fine machining techniques such as electrical discharge machining (EDM), laser ablation, and micro-milling. Unlike traditional moulds that can accommodate multi-cavity layouts, micro moulds are typically single- or few-cavity due to stringent dimensional controls.

Tolerances and Surface Finish

Achieving surface roughness as low as Ra 0.05 μm is not uncommon in μIM. In contrast, traditional moulds typically aim for Ra 0.2–0.8 μm, sufficient for most medical housings and connectors.

Thermal Management

Temperature control is far more critical in micro moulds due to small shot volumes and the rapid heat transfer required to avoid premature solidification. Conformal cooling, variothermal systems, and high-precision thermoregulation are often employed.

Machine and Process Considerations

Injection Units

Micro injection machines use precision screw or plunger systems, often with a shot-to-shot control resolution below 0.1 mm³. Traditional machines may lack the resolution required for such small volumes, making them unsuitable for micro components.

Process Stability and Repeatability

In micro moulding, even minor fluctuations in pressure or temperature can lead to part rejection. Therefore, μIM relies heavily on real-time process monitoring and closed-loop control systems. Traditional processes, while controlled, can tolerate a greater margin of variation.

Materials

Both processes utilise medical-grade polymers such as PEEK, LCP, PMMA, and PC. However, material selection in μIM must consider flow characteristics at micro-scale, including shear thinning and wall-slip phenomena.

Validation and Regulatory Compliance

Due to the critical nature of medical applications, both mould types must comply with ISO 13485 and FDA regulations. However, μIM often necessitates additional validation steps, including:

- Enhanced metrology (e.g., white light interferometry, micro-CT)

- Microscopy-based dimensional analysis

- Specialised DOE (Design of Experiments) for micro-scale process validation

Cost and Scalability

While traditional injection moulds offer lower cost per part at high volumes, the upfront tooling for μIM is significantly more expensive due to the required precision. However, for ultra-small parts, the material savings and functionality gains (e.g., integration of features into a single component) can offset these initial costs.

Application-Specific Considerations

| Application | Traditional Moulding | Micro Moulding |

| Syringe Barrels | ✓ | ✗ |

| Catheter Tips | ✓ | ✓ |

| Microneedle Arrays | ✗ | ✓ |

| Hearing Aid Components | ✓ | ✓ |

| Microfluidic Chips | ✗ | ✓ |

Both traditional and micro injection moulding have essential roles in the production of medical devices. Traditional moulds remain ideal for larger, less complex components where cost-efficiency and high throughput are key. Micro injection moulding excels in applications requiring miniaturisation, extreme precision, and integration of fine features.

Choosing the right moulding approach depends on part geometry, material selection, regulatory requirements, and the intended volume of production. As the demand for micro medical devices grows, μIM will continue to play a pivotal role in the evolution of next-generation healthcare technologies.

Micro Systems: Your Partner in Precision Medical Moulding

Micro Systems is uniquely positioned to support the medical sector with world-class expertise in both micro and traditional injection mould tooling. With in-house design, ultra-precision machining, validation, and cleanroom moulding capabilities, Micro Systems delivers turnkey solutions that meet the stringent quality and regulatory standards required for critical medical applications. Whether you are developing a novel drug delivery system, diagnostic platform, or implantable device, Micro Systems combines innovation with engineering excellence to bring your product from concept to market with confidence.

Contact us today!