Building a sustainable supply chain in the manufacturing industry

The importance of CSR in supply chain

Corporate Social Responsibility (CSR) is a sort of self-regulation practised by businesses with the goal of social accountability and having a good influence on society through a range of activities including but not limited to being environmentally sustainable and eco-conscious, fostering equality, diversity and inclusion in the workplace, treating employees with respect, giving back to the community through volunteering and donation, and ensuring ethical business choices.

Nowadays, contemporary supply chains are becoming global, more complicated, and multi-tiered, making unethical practices easier to occur without the brand’s awareness. Businesses hence need to be aware of the activities of not only their supplier, but also their supplier’s suppliers, and so on. Not being fully aware of the ethical levels of their whole supply chain could cost businesses significantly.

As CSR is becoming crucially important globally, 91% of customers want firms to act responsibly in order to address social and environmental challenges and 84% said they look for environmentally friendly items wherever feasible, businesses need to look at CSR in a bigger view, tracing back through their supply chain with great visibility and transparency. According to a survey, 66% of company executives say they have already begun changing suppliers that do not adhere to their corporate social responsibility standards in the recent year, and 92% of those asked indicated they now assess suppliers based on their social principles and effect, and 75% said a prospective supplier who does not share information about their social values will turn them down. A responsible supply chain would also assist to defend a brand’s reputation, foster long-term loyalty, and improve the consumer experience, as in a recent study, three-quarters of Millennials are prepared to pay more for environmentally friendly products. These numbers prove that building a sustainable supply chain is becoming a standard practice across industries, helping businesses become more transparent and meeting the tougher demands from the public and their business partners.

Moreover, sustainability regulations are becoming more stringent across the world, and it is critical that supply chains adhere to them to make sure the end products are accepted in the target market. The US Clean Water Act, for example, governs the discharge of contaminants into US waterways, or in the UK, the Modern Slavery Act of 2015 compels firms to declare how they evaluate their supply chains to prevent human rights violations each year.

Environment

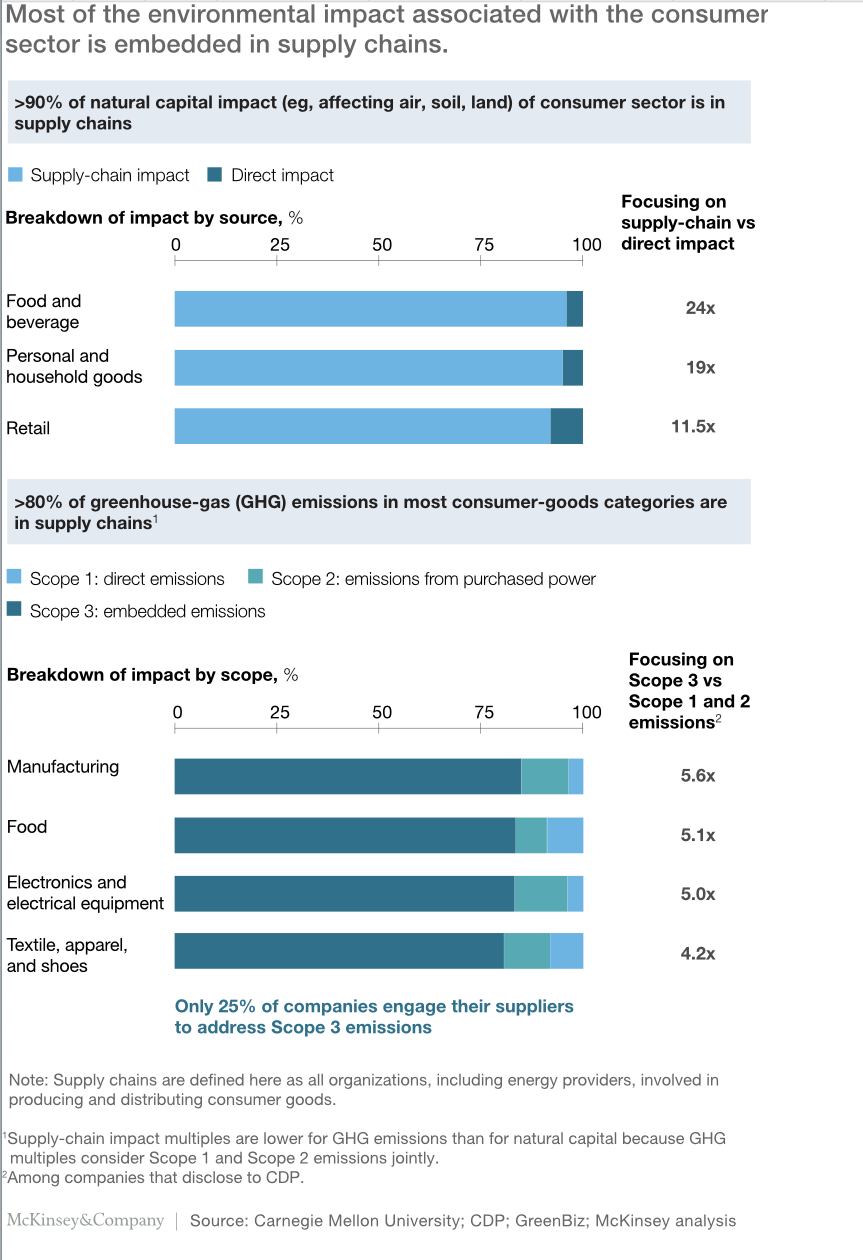

A business’s environmental impacts do not simply start at the business itself but throughout its supply chain, hence choosing eco-friendly partnerships with suppliers is a key step in minimising its environmental footprints. According to McKinsey, the average consumer company’s supply chain incurs significantly bigger social and environmental costs than its own activities, accounting for more than 80% of greenhouse-gas emissions and 90% of the effect on air, land, water, biodiversity, and geological resources.

Supply chains have a major role in the consumer sector’s environmental effect (Photo: McKinsey & Company)

The report Transparency to Transformation: A Chain Reaction also pointed out some shocking numbers:

- For the next 5 years, companies might incur expenditures of up to US$120 billion due to environmental concerns in their supply chains;

- Google, L’Oréal, Walmart, Braskem, and Toyota are among the 150+ big purchasers that have called for openness and action from suppliers to address these concerns;

- Supply chain GHG emissions are 11.4 times higher than operational emissions on average;

- Emission reduction reduces costs: Suppliers engaged in measures that reduced emissions by 619 million tC02e while saving $33.7 billion, which is the equivalent of 159 coal power plants operating for a year.

The study also found that notwithstanding COVID-19 demands, major corporate purchasers are increasing their demand for their suppliers to be open about environmental problems and take measures to mitigate them. In 2020, the number of purchasers requesting transparency through CDP‘s system increased by 24%, and they sought data from 15,600+ suppliers, representing a 19% rise over the previous year. This surge in market demand has been fueled in part by multinational corporations increasingly adopting science-based objectives, which often require them to reduce supply chain (Scope 3) emissions.

Social pillar

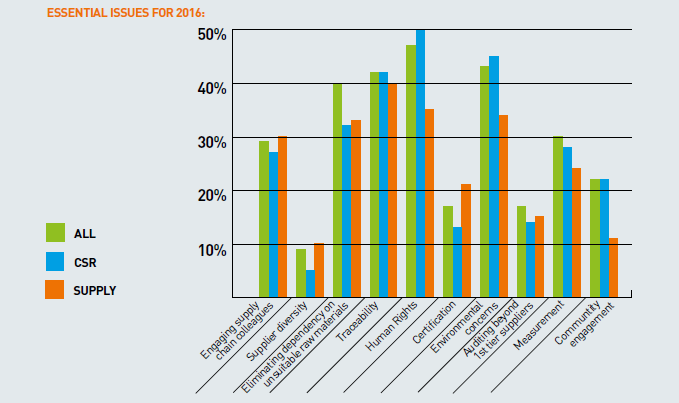

Social aspects covering workplace risk, occupational health and safety, human rights and fairness are all key criteria when analysing the CSR performance of suppliers, ensuring the highest level of ethical business practices as possible. Based on a survey by State of Sustainable Supply Chains (2016), 47% of respondents believed human rights to be an essential focus within their supply chain, followed by environmental concerns (43%) and traceability (42%). According to recent research, the ethical supply chain is also proven to be more evolving, as 69% of organisations polled are working to eliminate workplace prejudice, 57% are keeping an eye on work conditions and 56% are combating corruption (extortion, bribery).

Essential social issues (Photo: Source)

How to build a sustainable supply chain network?

As CSR could cover a wide spectrum of criteria, businesses need to first analyse and revise their current business models and resources, to identify and prioritise the suitable CSR criteria for their business in the short-term and long-term, such that they could achieve a stronger CSR performance without affecting their business operation. Some common CSR criteria that businesses could look for from their existing and potential buyers include:

- The environment: pollution control, resource sustainability, carbon footprint, renewable/non-renewable energy source, etc.

- Human rights: responsibility of care, discrimination, equal pay, protection from forced labour and trafficking, etc.

- Labour relations and working conditions: occupational health and safety, social discourse, wellbeing, work-life balance, health insurance, etc.

- Consumer concerns: fair marketing practices, data privacy, etc.

- Others: Corporate ethics, management, corruption, fair business practices, etc.

Some actions that businesses could take to secure a sustainable supply chain:

Supply chain mapping and transparency: The first stage in any transformation process should be to get a comprehensive awareness of the business’s existing ground reality with the help of technology. Businesses should start chasing the movement of products from the manufacturer to the customer, concentrating on sustainability aspects, paying attention to resource use, wasteful behaviours and process efficiency. By doing so, businesses could track how labour and resources are used at each level of the supply chain and identify particular areas for improvement.

To guarantee that suppliers are adhering to sustainability requirements, supply chain managers must have visibility into how they extract or create raw materials. Technology like Blockchain technology or Internet of Things (IoT) devices may be used to record and verify supplier sourcing practises. IoT devices may monitor and report on working conditions as well as environmental elements. Marketplaces may also help a company’s suppliers become more transparent. The more integrated they get, the more visible they become to people who have access to the internet.

Supplier engagement: Businesses need to engage with their suppliers and encourage the adoption of sustainable practices, by laying down compliance standards and performance metrics and conducting periodic audits. Businesses should also work with their suppliers to help them implement new processes aligned with collective sustainability goals. Other activities could include providing training programmes on sustainability best practices, communicating expectations on sustainable supply chain operations, instituting recognition/rewards programs for achieving sustainability goals.

There are also several international standards that businesses may expect from suppliers to ensure that they are trustworthy business partners. For example, ISO 14001 is a standard that demonstrates a company’s environmental practices, ISO 26000 standard is the first worldwide standard on social responsibility with the goal of assisting organisations in thinking strategically in order to implement ambitious CSR programmes. Global Reporting Initiative (GRI) 408 and 409 or Sustainable Accounting Standards Board (SASB) human capital practices reflect worldwide guidelines on child and forced labour concerns.

Set benchmarks and goals: Realistic, achievable targets enable businesses and suppliers to align plans and governance for sustainable performance. When paired with audits and incentive systems, these measures effectively drive sustainability across the supply chain. Where direct business rewards aren’t feasible, alternative incentives—such as enhanced branding or future opportunities—can also encourage supplier progress.

Planning and re-designing: Using the same suppliers, businesses could increase their sustainability through effective planning and better designing.

Misalignment between supply and demand, such as excess or insufficient raw materials, production, and distribution, leads to rework and waste. To address this, businesses must leverage predictive analytics, machine learning, and AI to forecast demand and optimise supply and production processes.

Firms can enhance transportation sustainability by reducing fossil fuel consumption, optimising routes, and maximising container utilisation. Predictive analytics enable efficient shipment consolidation, reducing greenhouse gas emissions per unit of cargo by optimising assets like containers and transportation.

As a leading micro moulding company in the UK with operations in Singapore with customers across continents, Micro Systems understands our key role in helping our customers achieve a more sustainable, ethical and resilient supply chain. With our effective supply chain management, in which the majority of our key suppliers are implementing successful CSR practices, we can ensure the highest standards, transparency and commitment to strengthening your sustainable supply chain network. For more information, please Contact us or visit our website.

As a leading micro moulding company in the UK with operations in Singapore with customers across continents, Micro Systems understands our key role in helping our customers achieve a more sustainable, ethical and resilient supply chain. With our effective supply chain management, in which the majority of our key suppliers are implementing successful CSR practices, we can ensure the highest standards, transparency and commitment to strengthening your sustainable supply chain network. For more information, please Contact us or visit our website.