Beyond Ultra-precision Lens Moulds

Since being founded in 2003, Micro Systems has been solving complex manufacturing problems in tooling and moulding for advanced applications in ophthalmic, medical, pharmaceutical, diagnostics and micro industries.

In 20 years of operation, Micro Systems and its’ subsidiaries have grown from a small team consisting of just a handful of people, to become a team of 100 talented people, with more than 800 square metres of clean manufacturing environment including Class 7 and 8 cleanrooms and white rooms in Haydock, UK, as well as a modern facility in Singapore, serving hundreds of customers from all over the world.

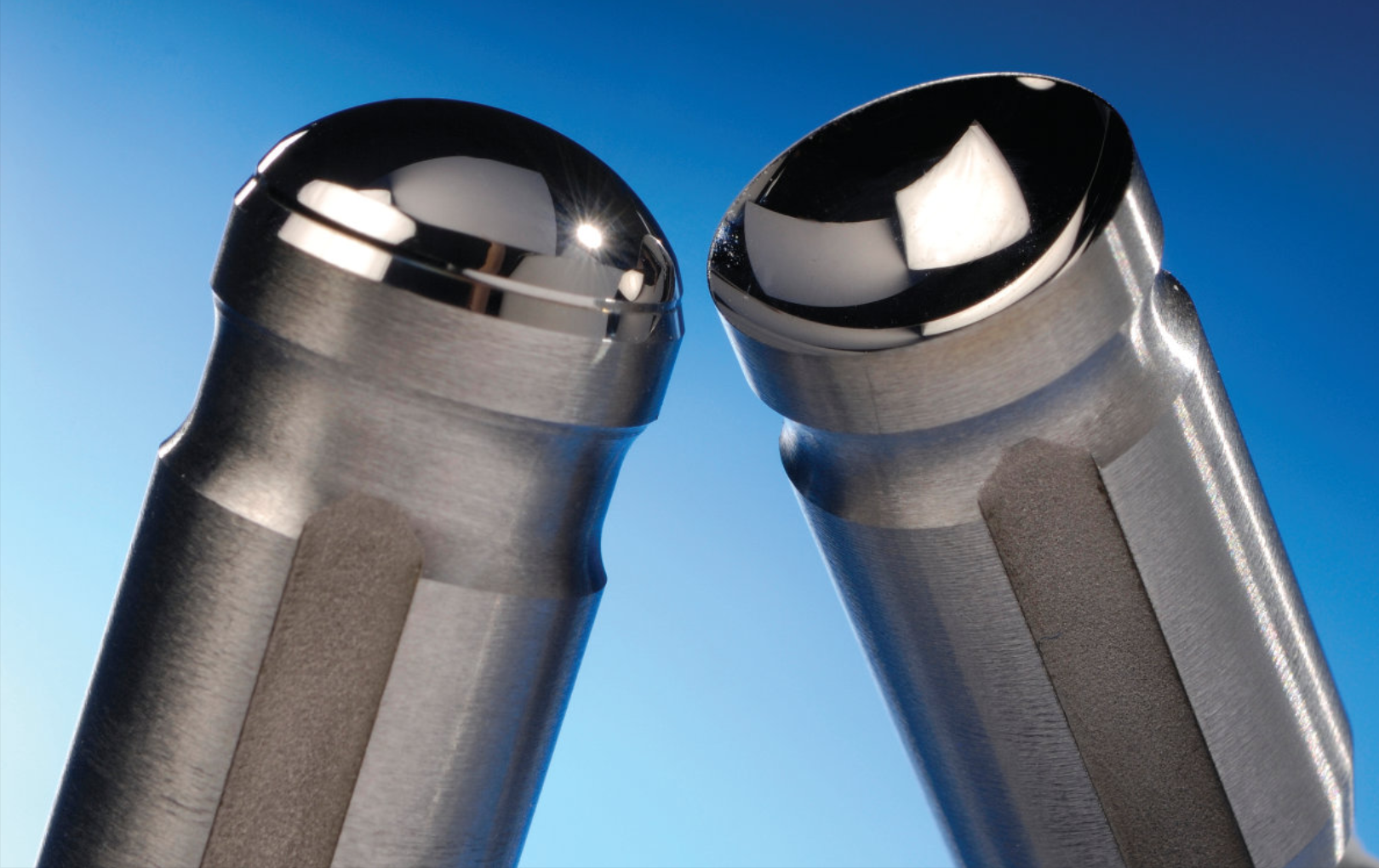

Photo: Hardened Steel inserts direct machined to ~20Nm Ra surface finish for lens and optical applications.

The forging of reliable and long-lasting partnerships between Micro Systems and world-leading ophthalmic OEMs, who share in Micro Systems’ vision and drive for continuous improvement and development of technologies to improve manufacturing efficiency, has enabled Micro Systems to invest heavily in the latest technology from design software to injection moulding machines and state-of-the-art metrology equipment. Micro Systems UK site in Haydock, UK is home to a wide array of the top-of-the-range machinery and equipment, from Agie EDM and WEDM, Kern Micro Milling machines, Studer Grinding machines, Wittmann-Battenfeld MicroPower micro moulding machines, as well the ultimate metrology equipment from vision systems, digital microscopes, white-light interferometers and an in-house CT Scanner equipped with leading GOM CAD comparison software, all of which allow Micro Systems to offer unrivalled services and products to OEMs, which improve stakeholder outcomes and, ultimately, end-products for consumers.

One such boundary constantly being pushed at Micro Systems is Cycle Time Reduction, with the adoption of conformal cooling technology reducing cycle times of lens packaging moulds by up to 70%. This has been achieved through a combination of enhanced mould cooling times due to the complex geometry of cooling channels now possible, as well as material reduction R&D, enhancing our customers ESG performance and enabling them to become more competitive in an environment in which ever-increasing importance is placed on sustainability goals.

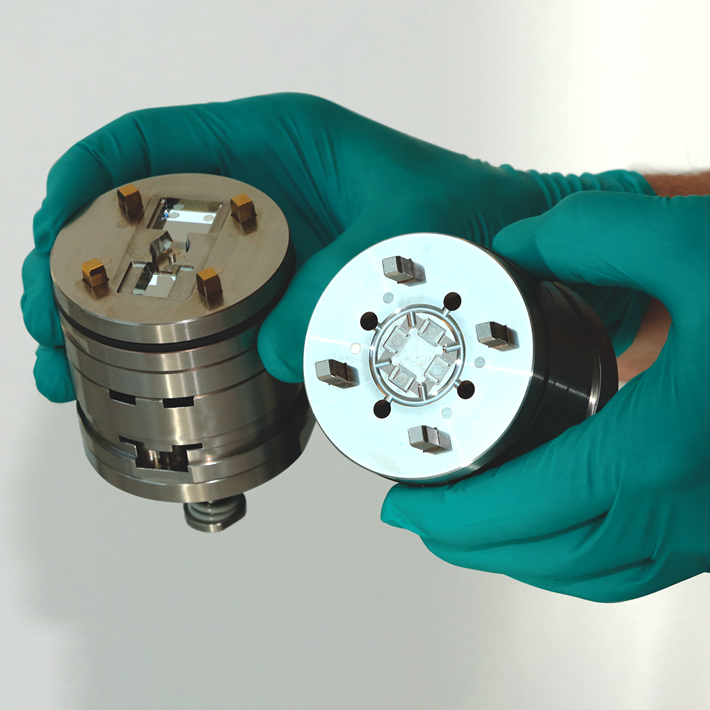

Other key innovations attributable to Micro Systems include our patented Quick Change Plate concept, enabling component reconfiguration for part customisation within a single mould, to reduce tooling costs and improve efficiency of production, and our bespoke in-mould adjustment mechanisms allowing for incremental adjustment to micron level.

‘Since the very beginning, Micro Systems has always been committed to providing the very best quality of products and service to our customers. We consistently achieve this through continuous improvement and by investing in the best equipment which empowers our staff to achieve their potential and push the boundaries of possibility in engineering.’

– Gary Clark, Founder, Managing Director of Micro Systems (UK) Ltd.

Micro Systems now proudly boasts world-leading capabilities in the manufacture of precision-engineered injection moulds and micro moulds for the medical, pharmaceutical and ophthalmic markets. Micro Systems offers innovative solutions for designing and manufacturing multi-cavity, high-volume fast-cycling moulds, as well as turnkey solutions for ophthalmic and medical device manufacturing needs, with Class-7 cleanroom production capabilities. In addition to mould making and component supply, Micro Systems also provides factory acceptance testing (FAT), mould validations and technical moulding support as part of our comprehensive service. The company is ISO 9001 and ISO 13485 certified, and has facilities in Haydock, UK and in Singapore.

Contact us today to discuss your Lens Mould project!