Accelerating Microneedle Innovation Through Precision Mould Tooling in Singapore

Manufacturing microneedle drug delivery systems is inherently complex, requiring micron-scale accuracy, material compatibility, and adherence to stringent regulatory standards. Singapore offers a unique convergence of infrastructure, technical expertise, and regulatory readiness, making it an ideal hub for end-to-end microneedle manufacturing, especially when partnering with advanced mould tooling specialists.

Precision Engineering Ecosystem for Micromoulding

Singapore’s manufacturing ecosystem is built on a foundation of ultra-precision engineering, ideal for microfabricated devices such as microneedles. Local toolmakers specialise in:

- Sub-micron machining and micro-EDM capable of producing features below 1 μm

- High-precision multi-axis CNC and micro-milling, enabling complex 3D tip geometries and tight tolerances across the tool cavity

- Optical surface finishing, achieving low Ra (<20 nm) for polymer transparency and biocompatibility

- Tool steels and coatings designed for high-wear resistance when processing bioresorbable or drug-loaded polymers (e.g. PLA, PLGA, COC)

These capabilities ensure dimensional accuracy, tip sharpness, and repeatability, all of which are critical for functional performance in microneedle arrays.

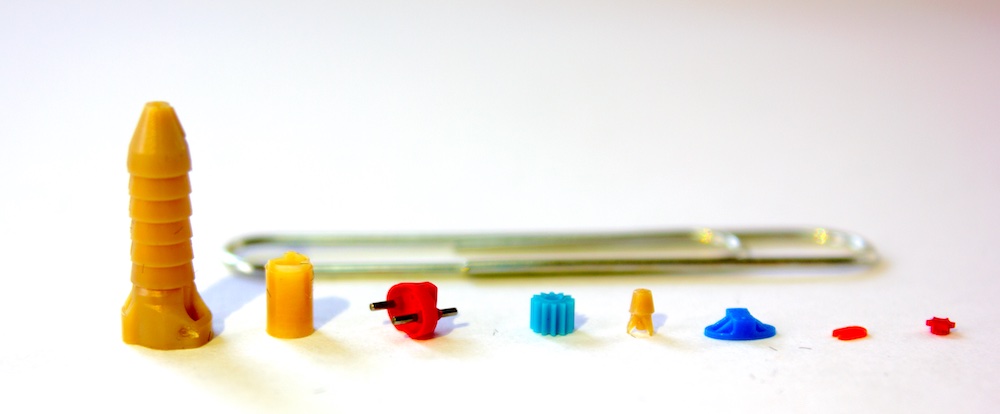

Micro mould tooling and micro injection moulding can help achieve outstanding precisions and dimensions in medical devices (Photo: Micro Systems)

Speed to Market: Rapid Tooling and Agile Production for Microneedle

In microneedle development, the ability to iterate quickly on tool design and molding parameters accelerates time-to-clinic and time-to-market. Singapore’s toolmakers and moulders offer:

- In-house tool design + machining, reducing lead times from weeks to days

- Pilot-scale tooling and short-run production, allowing clinical trial batches without scaling full production prematurely

- Simulation-driven mould design (Moldflow, Sigmasoft) for optimized filling of microcavities and cycle time reduction

- Co-located design, machining, and cleanroom injection moulding to streamline prototyping, validation, and scale-up

This vertical integration eliminates friction in the development pipeline, enabling faster iteration cycles and reduced development risk.

Regulatory-Ready, Medtech-Certified Infrastructure

Microneedles are regulated as combination medical devices, demanding compliance with global standards. Singapore offers:

- ISO 13485-certified manufacturers with experience in FDA/EMA submissions

- Cleanroom injection moulding facilities (Class 7/8), enabling sterile or low-bioburden production

- Validated processes (IQ/OQ/PQ) supported by digital manufacturing records for traceability

- GMP alignment and ready access to regulatory consultants, allowing faster approvals for clinical or commercial batches

This ecosystem enables regulatory readiness from day one, a critical advantage for startups and pharma partners alike.

Micro Systems’ ISO 9001 facilities for Medical mould tooling in Singapore

Talent and Technology: Bridging Engineering with Biotech

Singapore supports deep collaboration across disciplines through:

- Skilled technical workforce trained in mechatronics, biomedical engineering, and microfabrication

- Proximity to A*STAR, NUS, and NTU for R&D partnerships, materials science, and process validation

- Access to public-private consortia (e.g., SIMTech, ARTC) that offer joint development of micro-manufacturing technologies

- Embedded AI and digital twins for process control, ensuring consistent quality and predictive maintenance of tooling

This allows a microneedle project to tap into advanced design-for-manufacturability (DFM) principles from concept through to commercial scale.

Strategic Logistics and IP Protection

Singapore provides additional advantages in global supply chain and business continuity:

- Robust IP enforcement, crucial for proprietary microneedle designs and formulations

- Global logistics connectivity, facilitating rapid shipment of prototypes or final products to the US, EU, and APAC regions

- Political and economic stability, reducing operational risk for long-term manufacturing commitments

Micro Systems: Enabling High-Precision Microneedle Manufacturing

A standout example of Singapore’s capabilities is Micro Systems, a UK- and Singapore-based precision engineering company specialising in ultra-precision mould tooling and micro injection moulding for the medical and pharmaceutical sectors. Micro Systems brings nearly two decades of experience in toolmaking for complex, high-tolerance medical devices—including microneedles. Their Singapore facility features ISO 9001 certification, Class 7 cleanroom environments, and cutting-edge equipment such as 5-axis micro milling and micro-EDM. With integrated design, tooling, and injection moulding services, Micro Systems enables rapid prototyping, full-scale production, and validation under one roof—making them an ideal partner for biotech firms looking to bring microneedle innovations to market efficiently and compliantly.

Find us at:

Micro Systems Engineering Solutions Pte Ltd

JTC Medtech Hub 05-02, Singapore 618305