Choosing the Right Mould Materials for Diagnostic Device Components

Selecting the correct mould material is one of the most important decisions in medical device manufacturing, particularly for diagnostic device components. Whether you’re producing microfluidic cartridges, optical cuvettes, or precision housings, the mould steel or alloy you choose will directly affect part quality, production efficiency, and regulatory compliance.

Why Mould Material Matters in Diagnostic Device Manufacturing

Diagnostic devices often require:

- Tight tolerances (micron-level precision)

- Perfect optical clarity or fluidic performance

- Consistency across high-volume production

- Resistance to wear, corrosion, and cleaning agents

In ISO 13485-certified cleanroom environments, the wrong mould choice can lead to surface degradation, inconsistent parts, longer cycle times, or costly downtime.

Key Criteria for Selecting Mould Materials

1. Wear Resistance for High-Volume Medical Production

Highly filled polymers or glass-reinforced plastics, used in some diagnostic housings, can accelerate tool wear. Steels such as H13 (DIN 1.2344) or 420 stainless (DIN 1.2083) offer excellent wear resistance for long-life medical mould tools.

2. Corrosion Resistance in Cleanroom Environments

Polymers like PVC or sterilisation processes such as gamma irradiation can corrode standard tool steels. Using stainless steels or applying PVD coatings ensures extended tool life.

3. Thermal Conductivity for Faster Cycle Times

Beryllium copper alloys in core or cavity inserts dissipate heat quickly, reducing cycle times in injection moulding for medical devices. This is particularly useful for thick-walled diagnostic parts.

4. Dimensional Stability for Micro Injection Moulding

For microfluidic channels or precision sealing features, dimensional stability is critical. Pre-hardened steels like modified P20 grades maintain accuracy over repeated thermal cycles.

Common Mould Materials for Medical & Diagnostic Devices

| Mould Material / Grade | Hardness (HRC) | Benefits for Medical Moulding | Example Applications in Diagnostics |

| P20 Tool Steel | 28–32 | Cost-effective, easy to machine | Medium-volume moulds, non-optical housings |

| H13 (1.2344) | 48–52 | Excellent wear resistance, high toughness | Long-run tools for abrasive or filled polymers |

| 420 Stainless (1.2083) | 48–52 | Corrosion resistance, high polishability | Optical cuvettes, transparent microfluidic devices |

| Beryllium Copper | ~30–40 | High thermal conductivity, reduces cycle times | Core inserts, hot spots in multi-cavity tools |

| Stavax ESR | 50–52 | Premium stainless, ideal for optical & cleanroom use | High-end diagnostic cartridges and lens housings |

Special Considerations for Diagnostic Device Tooling

Optical Clarity Requirements

Optical-grade diagnostic components require mirror-polished mould cavities (SPI A1 finish or diamond-turned). Steels such as Stavax ESR or 420 stainless are ideal.

Microfluidic & Lab-on-a-Chip Devices

Micro injection moulding demands steels that maintain micro-scale EDM or laser-textured features without rounding or deformation.

Cleanroom Compliance

Moulds in ISO Class 7 or 8 cleanrooms must withstand frequent cleaning with biocompatible disinfectants without corrosion or polish loss.

Multi-Cavity Balance

High-cavity tools for diagnostic consumables (e.g., pipette tips, cuvettes) need uniform cooling. Strategic use of thermal-conductive alloys ensures part uniformity.

Enhancing Performance with Surface Coatings

Even premium steels can benefit from:

- PVD coatings (TiN, CrN, DLC) for wear and corrosion resistance

- Electroless nickel plating for cost-effective protection

- Nitriding for increased surface hardness

For medical moulding, all coatings must be biocompatible and resistant to sterilisation processes.

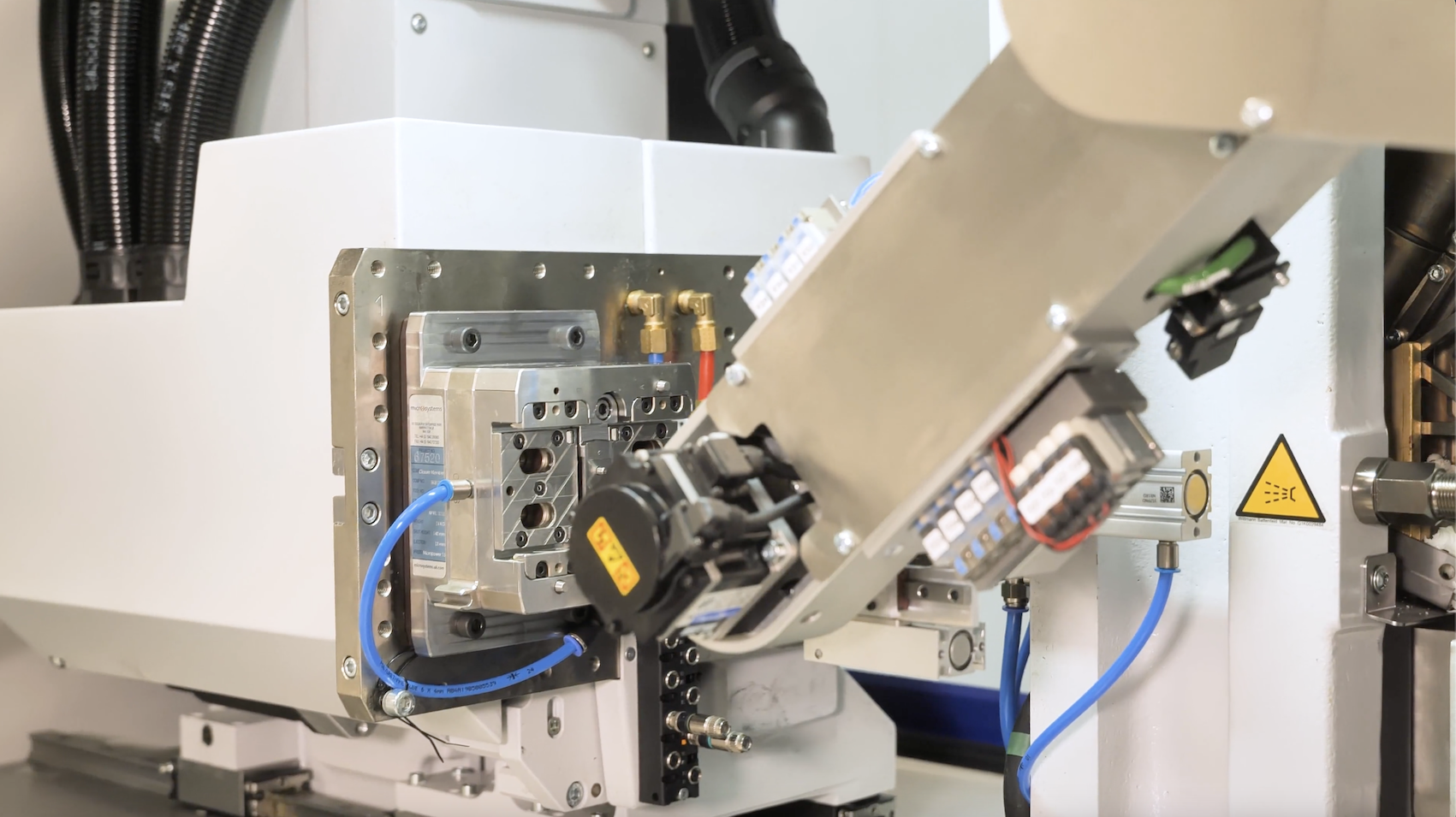

Why Micro Systems UK is the Ideal Mould Partner for Diagnostic Devices

Micro Systems is a leading specialist in precision injection mould tooling for the medical device and diagnostic sectors. Their unique capabilities make them the perfect partner for producing high-quality moulds for diagnostic device components:

- Proven MedTech Expertise: Extensive experience in ISO 13485-compliant environments ensures moulds meet stringent regulatory standards.

- Micro & Multi-Cavity Capability: Industry-leading micro injection moulding expertise allows for ultra-fine feature replication, essential for microfluidics and lab-on-a-chip devices.

- Integrated Design-to-Tooling Service: From CAD design optimisation to final mould validation, Micro Systems provides a full end-to-end service.

- Advanced Manufacturing Technology: Utilising high-precision CNC, EDM, and laser texturing equipment to achieve micron-level tolerances.

- Cleanroom-Ready Tooling: All moulds are built to withstand frequent cleanroom cleaning and sterilisation without loss of surface finish.

- Global OEM Partnerships: Trusted by top-tier diagnostic device manufacturers worldwide.

With state-of-the-art facilities and a track record in delivering moulds for some of the most complex and high-precision diagnostic components, Micro Systems UK helps clients bring reliable, compliant, and cost-effective medical products to market faster.

Choosing the right mould material for diagnostic devices is about balancing precision, durability, and cleanroom compatibility. By considering wear resistance, corrosion resistance, thermal conductivity, and micro-scale precision, manufacturers can ensure high-performance moulds that meet both technical demands and regulatory standards.

Contact us today!