What Is IOL Moulding? A Technical Guide to Intraocular Lens Manufacturing

The intraocular lens (IOL) is a critical implant used in ophthalmic surgery, most commonly to replace the natural lens during cataract removal or for refractive correction. IOLs must meet rigorous standards for optical clarity, dimensional precision, and long-term biocompatibility. At the core of this production lies IOL moulding, a high-precision manufacturing process that combines micro-engineering, advanced polymers, and controlled processing environments.

What Is an Intraocular Lens (IOL)?

An intraocular lens (IOL) is a synthetic, implantable optical device that replaces the eye’s natural lens, typically after cataract extraction or as part of a refractive lens exchange. IOLs are designed to focus light precisely on the retina, restoring clear vision and often reducing or eliminating the need for corrective eyewear.

There are several types of IOLs in clinical use, including:

- Monofocal IOLs – Provide clear vision at one distance (typically far).

- Multifocal and Trifocal IOLs – Allow for vision at multiple distances.

- Toric IOLs – Correct astigmatism.

- Accommodative IOLs – Mimic the natural focusing ability of the eye by shifting position or shape.

IOLs are generally manufactured from biocompatible polymers such as hydrophobic or hydrophilic acrylics and must meet stringent optical and mechanical performance criteria over a lifetime of use within the eye [1].

What Is IOL Moulding?

IOL moulding is the process of forming intraocular lenses by shaping biocompatible polymers within precision-engineered moulds. Two primary moulding techniques are used in the industry:

- Compression Moulding – Typically used for hydrophilic acrylic materials. A pre-polymer gel or sheet is placed between two high-precision mould halves and cured under controlled temperature and pressure. This process ensures exceptional optical surface quality and is ideal for monofocal and multifocal IOLs [2].

- Injection Moulding – More common for hydrophobic acrylics or PMMA-based lenses, where the molten polymer is injected at high pressure into a steel mould cavity. Injection moulding is well-suited to high-volume, automated production, offering high repeatability and efficiency [3].

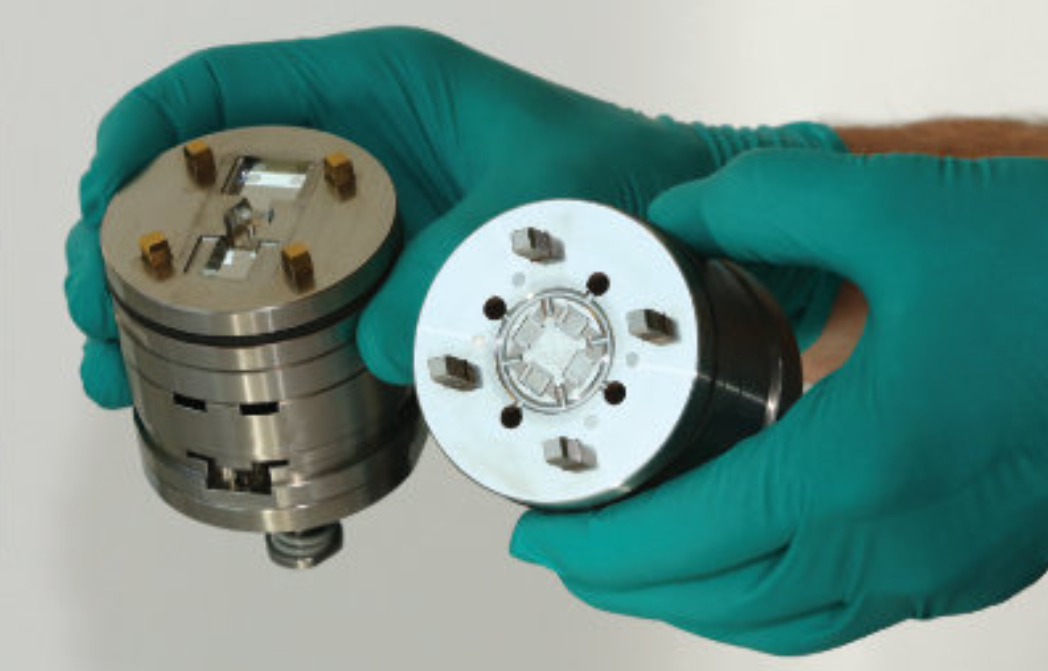

Both methods demand extreme tooling accuracy, often at sub-micron tolerances, to ensure the optical fidelity of the finished lens.

Tooling, Tolerances, and Surface Finishing

IOL moulds are typically manufactured using ultra-precision machining techniques, including diamond turning, electrical discharge machining (EDM), and CNC micromachining. These allow for the accurate reproduction of complex geometries such as aspheric or toric surfaces.

Surface finishes on optical moulds often reach Ra < 10 nm, which is critical for reducing scattering and ensuring lens clarity [4]. Post-machining, the moulds undergo multiple polishing stages and are inspected using non-contact interferometry to verify curvature and surface roughness. Even the slightest deviation can lead to aberrations in the optical profile of the intraocular lens.

Polymers and Curing Processes

The choice of material plays a major role in IOL performance. Common IOL materials include:

- Hydrophilic Acrylics – Known for foldability and biocompatibility. Typically used in compression moulding.

- Hydrophobic Acrylics – Offer reduced posterior capsule opacification (PCO) and are favoured in injection moulding applications.

- PMMA (Polymethyl Methacrylate) – Historically used, now largely replaced by foldable polymers for ease of surgical delivery [5].

These polymers require UV or thermal curing depending on formulation. Post-moulding steps include annealing to relieve internal stress, hydration (for hydrophilic lenses), laser marking, and final optical inspection. All processes are conducted in cleanroom environments to meet ISO 13485 and Class 7/8 cleanliness standards [6].

Why Micro Systems Leads in Intraocular Lens Moulding

Micro Systems is globally recognised for delivering ultra-precise mould tooling and cleanroom manufacturing solutions for the intraocular lens sector. Their experience spans:

- Design and manufacture of single- and multi-cavity IOL moulds

- High-tolerance lens inserts machined to nanometre specifications

- In-house metrology and validation, including white light interferometry

- Process development support for Class III implantable medical devices

Our cleanroom assembly capabilities and custom tooling solutions ensure regulatory compliance and production scalability, whether for monofocal, toric, or accommodating IOL platforms.

📍 Meet Micro Systems at MedTech Ireland 2025 on 24-25 September 2025 at Galway Racecourse, Ireland to explore their latest solutions in high-precision IOL tooling and automated lens manufacturing. Speak to their experts about upgrading your production workflow and achieving exceptional optical outcomes.

With increasing global demand for cataract and refractive surgeries, the need for precision-manufactured intraocular lenses continues to grow. Through the integration of micro-moulding technology, advanced materials, and automated cleanroom processes, IOL manufacturing has become a showcase of modern medical engineering. Choosing a trusted partner like Micro Systems ensures you remain at the forefront of innovation in intraocular lens production.

References

- Apple DJ, Mamalis N, et al. “Complications of Foldable Intraocular Lenses”, Survey of Ophthalmology, Vol. 48, 2003.

- G. Auffarth, N. Tetz, et al. “New Developments in Foldable Intraocular Lens Materials”, Journal of Cataract & Refractive Surgery, Vol. 36, 2010.

- Bhattacharjee, H. et al. “Injection Moulding Techniques for IOL Manufacturing”, Indian Journal of Ophthalmology, Vol. 64, 2016.

- Y. Zhou, T. Nakamura. “Surface Quality Evaluation for Optical Mould Inserts”, Precision Engineering, Vol. 45, 2016.

- Apple DJ, Mamalis N, et al. “Complications of Foldable Intraocular Lenses”, Survey of Ophthalmology, Vol. 48, 2003.

- ISO 13485:2016 – Medical Devices – Quality Management Systems – Requirements for Regulatory Purposes.