Design for Manufacturing in Mould Design and Manufacture

What is Design for Manufacturing?

Design for Manufacturing (DFM) is a critical aspect of product development, focusing on optimising a product’s design to streamline the manufacturing process. DFM is an engineering approach that prioritises manufacturability during component or tool design, resulting in a more efficient and cost-effective end product. By applying DFM principles, manufacturers can simplify, iterate, and optimise designs before production, reducing manufacturing costs and improving overall product performance. This makes DFM increasingly vital for companies across various sectors in today’s highly competitive global marketplace.

What are the principles of Design for Manufacturing?

The Design for Manufacturability (DFM) process examines five key elements: process, design, material, environment, compliance, and testing. This approach enables engineers and designers to create components that are both simpler to produce and more cost-effective.

Process

It’s crucial to carefully evaluate general criteria like cost and production volume when choosing the optimal manufacturing method for a certain product. Instead of only choosing the least cost approach, designers and engineers must also thoroughly consider all of the production possibilities available in order to determine which is the best one.

Design

Applying DFM concepts to production requires careful consideration of product design, since even little changes may have a significant impact on lead times and prices. Generally, going with a straightforward design is the best option. Not all designs can be so basic, but producing a design that is too complicated carries a higher level of risk. Hence, using DFM techniques for design analysis is essential to staying competitive in the market.

Material

Early material selection can help manufacturers save both money and time. Both price and quality are impacted by the chosen materials. When selecting materials, a few factors come into play, including conductivity, flammability, mechanical qualities, and thermal properties, to determine the optimal choice.

Environment

The quality standards of a product are heavily influenced by its intended operating environment. All operational conditions must be considered, ensuring each component performs under these circumstances. For instance, moulds used in medical environments, especially for internal medical parts, must meet higher standards. However, given the importance of production costs, DFM principles require designers to ensure that quality targets are both achievable and realistic.

Testing

Thorough testing is essential at every stage, ensuring all components and products meet industry standards. To avoid production issues, manufacturers should incorporate testing during the design phase. Addressing issues at later stages of development is considerably more costly, so DFM principles advocate for compliance testing prior to mass production.

Design for Manufacturing in Mould Design and Manufacture

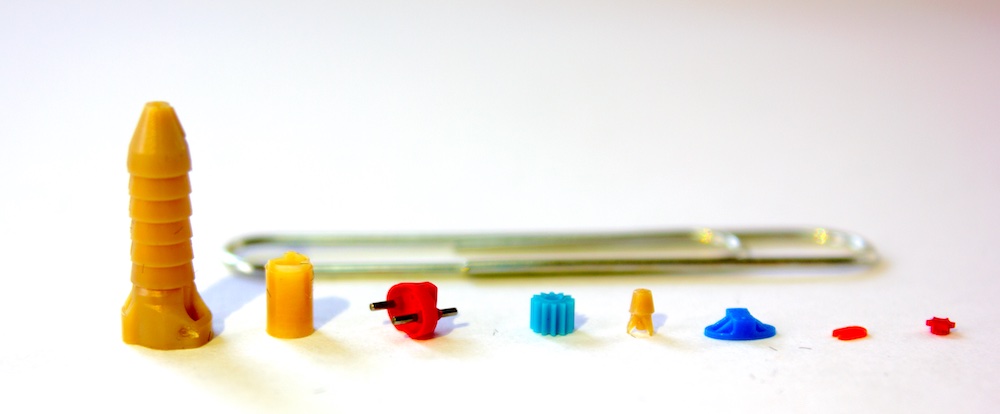

For a successful Mould manufacture and hence Plastic injection moulding project, the concept of Design for Manufacturing could simplify, optimise, and refine the product design to provide a more cost-effective, efficient product. DfM can also help guarantee manufacturing feasibility, minimise part failure and determine the complexities of manufacturing.

In mould design and manufacture, factors like draft angle, uniformity of wall thickness, location of gates, venting, edge radius, undercuts, texture and surface finish, tolerances are crucial to be considered. Besides, tooling consideration is also essential, hence designers should work closely with the tool maker to make sure the material qualities and part design match the mould design. Designers should also determine the optimal number and complexity of mould cavities by considering the demands of the manufacturing volume. For assembly and post-processing, designers need to incorporate features like self-locating tabs, snap fittings, and mating surfaces into your components design to make assembly simple, at the same time, reduce the amount of post-processing or secondary processes that are required.

The selection of plastic material for the injection moulding process is critical to DfM for moulds. The shrinkage rate of the plastic resin is one of the most challenging variables to control during moulding. Factors such as resin chemistry, fillers, additives, and component geometry all influence this rate. To optimise these key aspects, product designers and tooling engineers must maintain close collaboration to ensure the final mould is tailored for the specific plastic material selected.

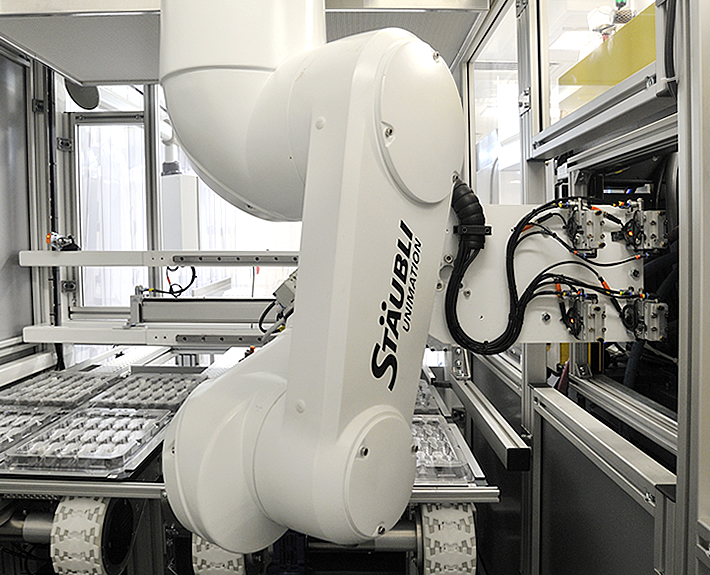

Choosing the correct manufacturing partner is crucial to the financial situation and level of achievement of a successful mould design and manufacture project. When it comes to mould tooling, professional toolmakers like Micro Systems will fully support their clients through a Design for Manufacture (DFM) process to help save time and money. As one of the leading mould tool makers in the UK and the world, our team of toolmakers at Micro Systems has years of experience designing and manufacturing ultra-precision moulds for the Medical, Pharmaceutical, Ophthalmics and Diagnostics industries.

Contact us today to discuss your Mould Manufacture project!