What is 2k injection moulding?

What is 2k injection moulding?

In 2K injection moulding, also known as 2-shot moulding, two materials or colours are processed into a single plastic component. This technique, utilising a 2K injection moulding machine, combines two distinct materials or colours, merging their unique properties into a high-performance, unified final product.

What is the 2k injection moulding process?

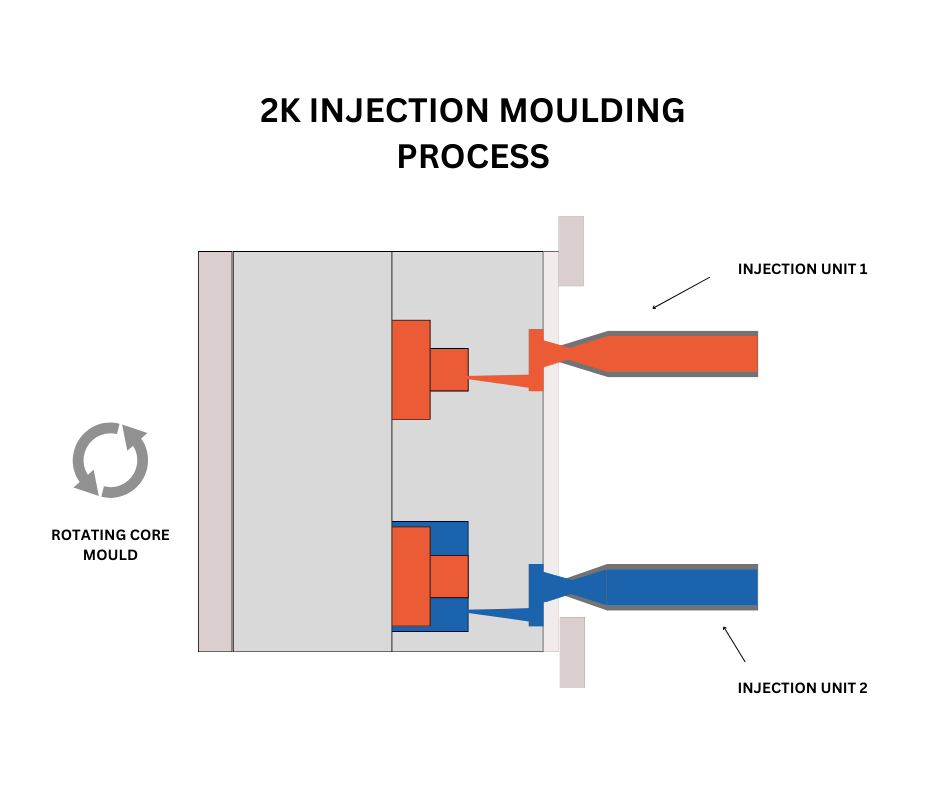

In the 2K moulding process, two materials are simultaneously injected into the mould cavity. Typically, this involves an elastic material such as TPE or TPV, combined with a rigid material like polypropylene. This dual-material approach allows for more complex designs and enhanced functionality compared to conventional single-material injection moulding.

Step 1: The two injection canisters are filled with raw ingredients, which are then heated and under pressure to preserve the viscous condition required for injection to take place. While the other moulding box stays closed, the first crate is opened and shot with the first injection.

Step 2: The part that was just formed from the first injection is robotically moved to the second mould as soon as the press on the first crate is opened. Thus, the first chamber is once more open and prepared for the second injection.

Step 3: After closing the second chamber’s press, the second injection is fired into the first chamber, which is now open, until it fills up just like the first one did, guaranteeing that the final items are uniform.

Step 4: Robotic arms are used to open the second chamber once more and move the second portion inside. This procedure is carried out as quickly as possible until the necessary quantity of goods is reached.

What are 2k injection moulding advantages?

- Improved aesthetics: The 2K injection moulding technique may be more appealing as it allows for the manufacture of two colours (2K) of the product in a single production process. Modification is hence easier to be added, for extra features like logos, patterns, colours, etc.

- Improved efficiency: Since the majority of it is automated, manufacturers can save a significant amount of time and money that would have been spent on labour expenditures.

- Design range: 2k moulding offers a lot of alternatives and is a good way to manufacture metallic mould items and transparent plastic at a reasonable price, and designers can be more flexible with their design choices.

- Reduced post-processing: The all-inclusive nature of the two-shot injection method eliminates the need for additional steps like post-processing, which typically result in needless increases in expense, time, and energy use, at the same time, increasing the precision of the final product.

- Part perfection: Conventional manufacturing techniques typically produce separate components in individual batches, which are then assembled, resulting in resource inefficiency. Two-shot injection moulding reduces the number of required parts, saving time, cost, and energy, while minimising the risk of errors between the two materials.

- Reduced time: The secondary processing time is not necessary during the 2k moulding process.

What are 2k injection moulding applications?

Two shot moulding design injection, or 2k injection moulding, is a highly adaptable process that may be used to make complicated and complex components with a variety of design elements. The medical sector is the most frequent user of this moulding technique. For example:

- Medical instruments: 2k moulding is useful in the medical profession for applications such as ergonomic handles with soft-touch grips, multi-material housings for medical instruments, and over-moulded grips for surgical tools.

- Automobile industry: 2K injection moulding is extensively used in the automotive industry to produce components such as multi-material gaskets, instrument panels, and gear shift knobs, where the combination of flexible and rigid materials is essential.

- Consumer Electronics: Both soft-and hard-touch surfaces are needed for many electrical components. Products like smartphone covers, remote control buttons, and electrical enclosures with integrated seals are made with 2k injection moulding.

What are the mould requirements for 2k injection moulding?

In order to guarantee that the two materials are injected correctly and that the final product satisfies the required criteria, the mould design and manufacture for 2k moulding is an essential part of the process. The two-shot mould must be designed with two separate chambers to prevent material leakage between them. Additionally, the mould requires adequate cooling channels to ensure proper cooling and solidification of the materials during the moulding process. It should also be capable of rotating 180 degrees, with symmetrical inserts to facilitate the correct material injection.

2k injection moulding vs over moulding

Another kind of injection moulding technique that enables the blending of two or more distinct materials into a single product is over moulding. A stiff plastic foundation component is often covered with a thin, malleable layer of thermoplastic elastomer (TPE) or other material utilising a 1 shot (insert moulding) or 2 shot (2k) process.

While sounded similar, 2k moulding and over moulding share certain key differences:

- Number of shots: Over moulding can be done in two steps or in one shot (insert moulding). Two-shot moulding is all that 2K moulding is.

- Amount of production: When it comes to larger operations, 2k is typically much larger than over moulding.

- Material: The material used in the over moulding process needs to be cool in order to be removed. However, as the polymer is usually still heated and flexible after 2k moulding, it offers additional utility. A wide range of materials may be moulded on or used as the moulding substance thanks to 2k moulding, however, there are limitations on the materials that may be used for over moulding.

At Micro Systems, our team of experts in injection moulding can provide turnkey solutions for your 2k moulding projects, for a variety of applications in the medical and pharmaceutical, diagnostics, drug delivery and other applications. We are ISO 9001 and ISO 13485 accredited, with ISO Class 7 cleanrooms and more than 20 years of experience supplying precision moulds and injection moulding solutions to major life sciences companies all over the world.

Contact us today to discuss your 2k injection moulding project!