Design for Sustainability and its future in manufacturing

What is Design for Sustainability?

Design for Sustainability (DfS) is an integrated approach that prioritises environmental and social well-being in product design (Mazini, 2020). It focuses on resource efficiency, the use of eco-friendly materials, and the broader impacts on people and communities. DfS considers the long-term sustainability of products, ensuring that future generations’ needs are not compromised. With growing consumer demand and industry emphasis on sustainability, the DfS approach has become increasingly relevant, particularly in the development of new products and processes.

According to the European Commission’s Sustainable Product Policy, up to 80% of a product’s negative environmental effect is finalised at the design stage, as a result, it is critical to analyse and minimise environmental implications during the design process.

By applying DfS, businesses can guarantee that products and services aim to minimise negative environmental and human health effects during their entire lifespan. It inspires designers and manufacturers to think about how to use more abundant and readily available basic materials or more readily recyclable materials and waste-reducing design approaches. It also encourages engineers to consider if sustainable transportation choices may be employed to minimise pollution and greenhouse gas emissions, and urges managers to design such that they can source materials more sustainably, both socially and environmentally.

Towards Circular Economy

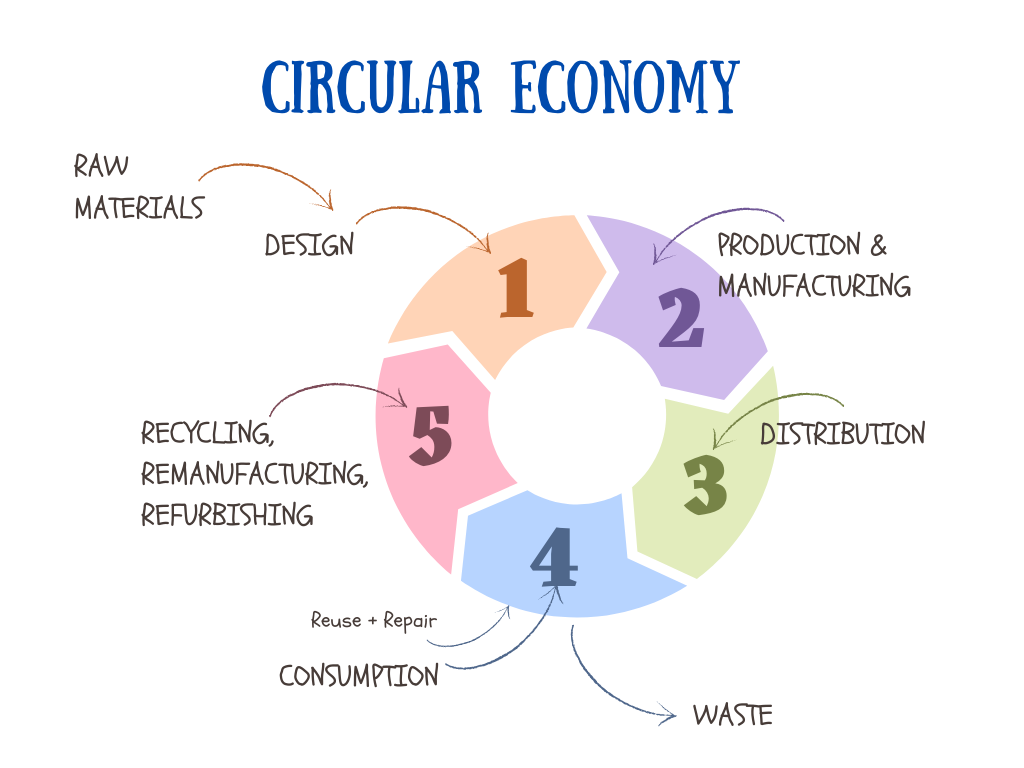

Moving away from the traditional linear economy of Take-Make-Consume-Throwaway, the world is working towards the concept of Circular Economy. This growing popular concept includes sharing, reusing, repairing, remanufacturing, and recycling products and resources in order to extend their life cycles and reduce total waste. This starts with the design stage, when value is added to the goods, allowing them to circulate within the system for as long as feasible. This is a preventative strategy that supports the overall aim of minimising waste and managing the world’s limited resources. According to a report by the University of Cambridge, the movement towards Circular Economy could help increase resource productivity by 3% annually, generating over 200,000 jobs and a growth of 7% in GDP by 2030 compared to the current model.

Factors of Design for Sustainability

To incorporate sustainability and circularity concepts throughout processes, production operations, goods, and product consumption, manufacturers must innovate and restructure their present operating models. Businesses could achieve this by pursuing an ecosystem-driven approach that satisfies their demands from design through consumption and further reuse, repurposing, or remanufacturing, such that satisfying the Scope 1, 2, and 3 compliance requirements by default. However, for certain industries with strict laws, codes and standards, design changes can be more difficult, and the expenses of redesign, requalification and certification are sometimes prohibitive, hence, it is important for manufacturers to analyse their current situations and the industry requirements, to choose and prioritise the suitable elements based on their resources.

Material selection

Sustainable material selection involves a careful balance between meeting design requirements, reducing environmental impact, improving product performance, and achieving cost objectives. This process can be time-consuming and costly, as it requires evaluating extensive information from various stakeholders while ensuring the materials meet established performance standards.

Materials should be recycled, renewable, non-toxic, or sustainably sourced, while still fulfilling the necessary design specifications. Packaging material selection is equally crucial, as it should enhance product utility for consumers, be environmentally friendly, and easily recyclable. In B2B contexts, returnable packaging for reuse is also a viable option in many cases.

Design for disassembly

Reusing a product’s original components, either in the same or new products, offers significant environmental benefits by reducing the need for raw materials, the energy required for extraction, and minimising waste when done correctly. Designers should focus on using durable, high-quality materials with components that are easy to disassemble and designed to last beyond the product’s initial use. Key considerations for designing for disassembly include material quality (for hygiene and strength), ease of disassembly, fastening methods (e.g., glue, screws, or snap-fit connections), responsibility for managing disassembled parts, and providing clear instructions to guide users in the disassembly process.

Design for durability

The durability of a product plays a crucial role in minimising both economic and environmental impacts, ultimately enhancing sustainability throughout its life cycle. A durable design typically consumes fewer resources, reduces energy use, generates less waste, and distributes environmental impacts over a longer lifespan. It also requires less maintenance, boosts business reputation for high-quality products, and enhances customer satisfaction. According to the Ellen MacArthur Foundation, product durability is defined by:

- Physical endurance: Mixing material selection, including component reinforcement, to create very durable items that can withstand damage over time.

- Emotional endurance: Using tactics to grow and sustain a product’s relevance and attractiveness to users, or a group of users, over time.

- Remake and recycling: Creating items that can be dismantled and their components and materials reused or recycled to create new products.

According to a survey by Eurobarometer, in the EU, 69% of consumers want their mobile phones and tablets to last at least 5 years, however, due to battery degradation, most users are forced to replace their gadgets every 2 years. If designers improved battery performance, the device would be more likely to reach its projected life of 5+ years because all other components are still functional after 2 years.

Yet, due to factors such as existing technology and material solutions, these design considerations will almost certainly include certain trade-offs that businesses need to be aware of.

Design for reusability

Recycling involves converting an object into its basic elements for creating a new product, typically through an energy-intensive process. In contrast, reusing an object means utilising it as is, without modifications, reducing waste and pollution, and enhancing sustainability. For reuse, a product must be reliable, durable, lightweight, and able to maintain its quality, making material selection crucial. Additionally, adopting modular design provides further advantages, simplifying repair, refurbishment, and eventual recycling.

Renewable

Active products, which require a continuous or periodic energy source to operate, increasingly rely on electric drives, particularly in the automobile and shipbuilding sectors. To create more sustainable designs, designers should prioritise renewable energy sources, either as primary or secondary options. Emphasising alternatives such as wind, solar, and hydroelectric power, rather than traditional fuels like petrol, diesel, gas, and coal, promotes sustainable growth while enhancing living standards for both consumers and businesses.

With offices in 2 different continents, we pride ourselves on the ability to generate positive impacts where our businesses operate. Learn more about our great works so far with our CSR Report!

Working closely with our customers from the first stages, from design to manufacturing, enables Micro Systems (UK) to maximise design efficiency and simplify production, hence resulting in a higher level of sustainability of the final products for both ourselves and our customers. Contact us today to start planning your mould design, mould manufacture, injection moulding project!